Engine

SHOP MANUAL

Ch 1 page 25

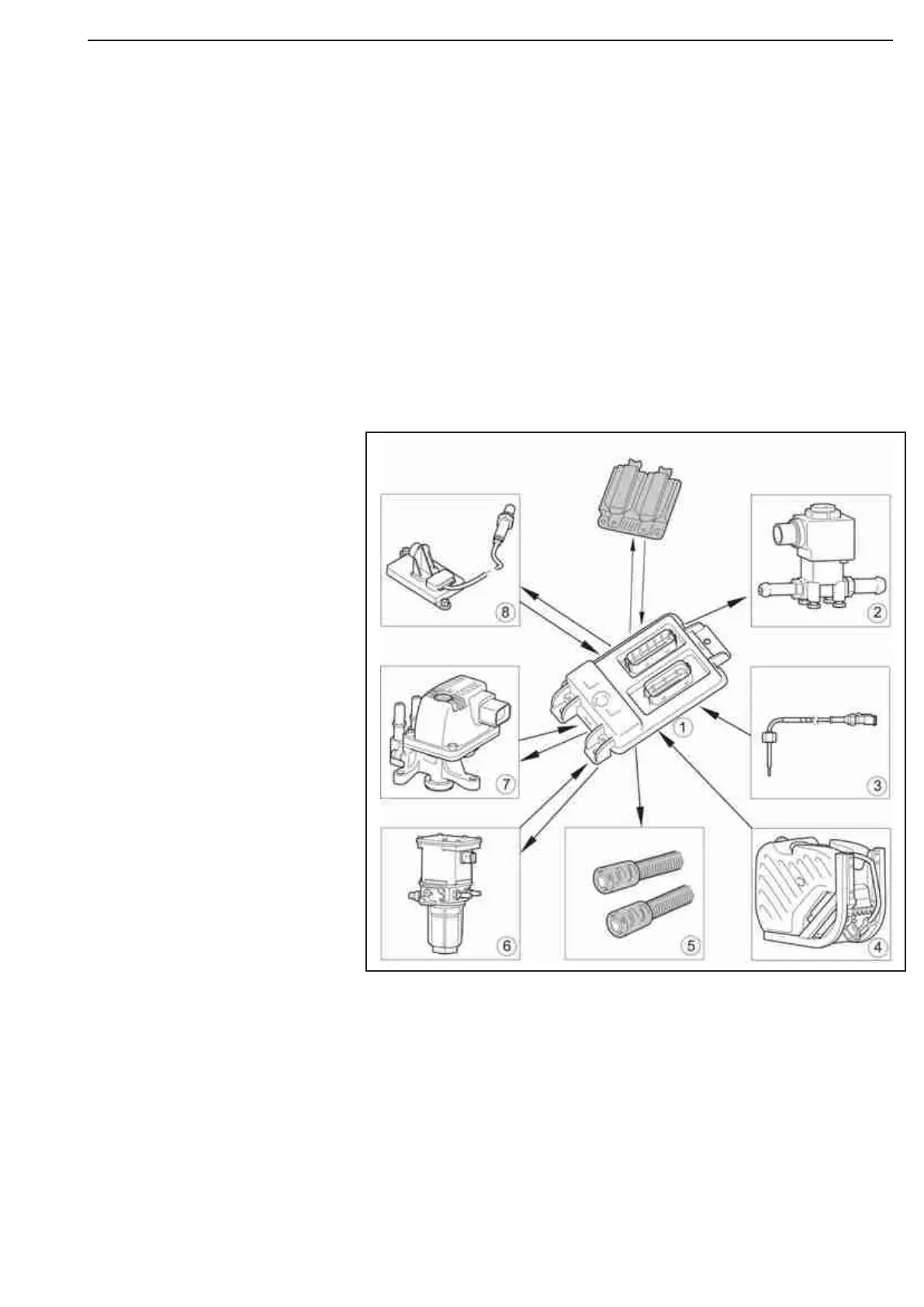

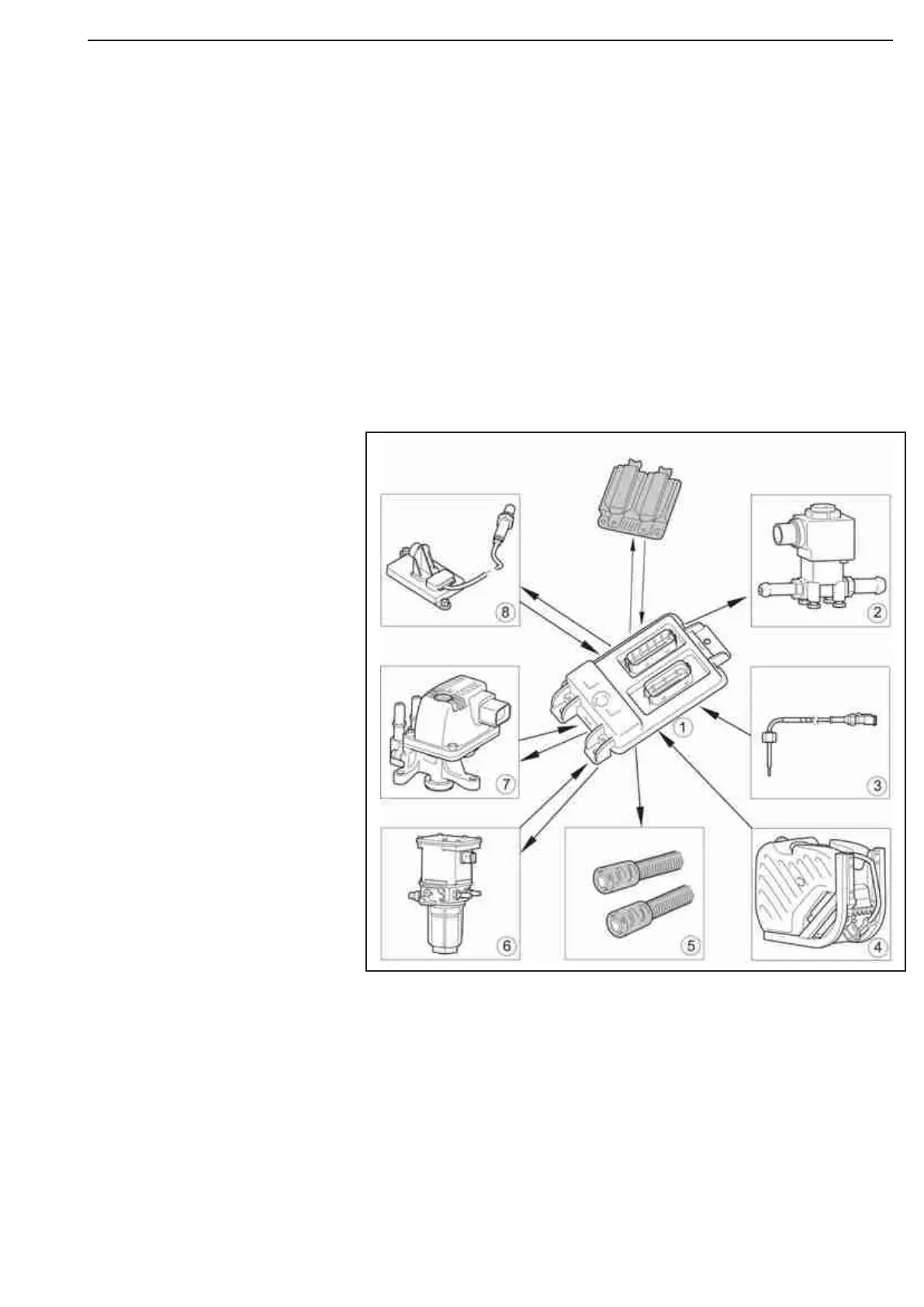

Control system for exhaust gas aftertreatment

Overview - Exhaust gas aftertreatment system structure and components

Exhaust gas aftertreatment is made up of the electronic control system for exhaust gas aftertreatment, EEC

(Exhaust Emission Control system), with sensors and electrical components such as the reductant pump

and reductant doser. Together with components such as catalytic converters, reductant tank and electrically

heated reductant hoses, the exhaust gases are cleaned to remove harmful substances.

Control system for exhaust gas aftertreatment

The control system consists of a control unit (EEC3), NOx sensor, temperature sensor for exhaust gases,

level and temperature sensor in the reductant tank, reductant pump, reductant doser, coolant valve and elec-

trically heated reductant hoses.

1 Control unit EEC3

2 Coolant valve

3 Temperature sensor

4 Level and temperature sensor

in reductant tank

5 Electrically heated reductant

hoses

6 Reductant pump

7 Reductant doser

8 NOx sensor

Control unit EEC3 (E67)

The EEC3 control unit retrieves data from the system’s sensors and components. EEC3 communicates with the

engine control unit EMS. EMS decides on what measures are to be executed, e.g. what quantity of reductant is

to be metered to the exhaust gases, and notifies EEC3. The EEC3 control unit is independently responsible for

the functions which supply reductant to the exhaust gases.

The EEC3 control unit is located on the reductant tank bracket underneath the reductant tank.

Figure 38

Loading...

Loading...