Engine

SHOP MANUAL

Ch 1 page 233

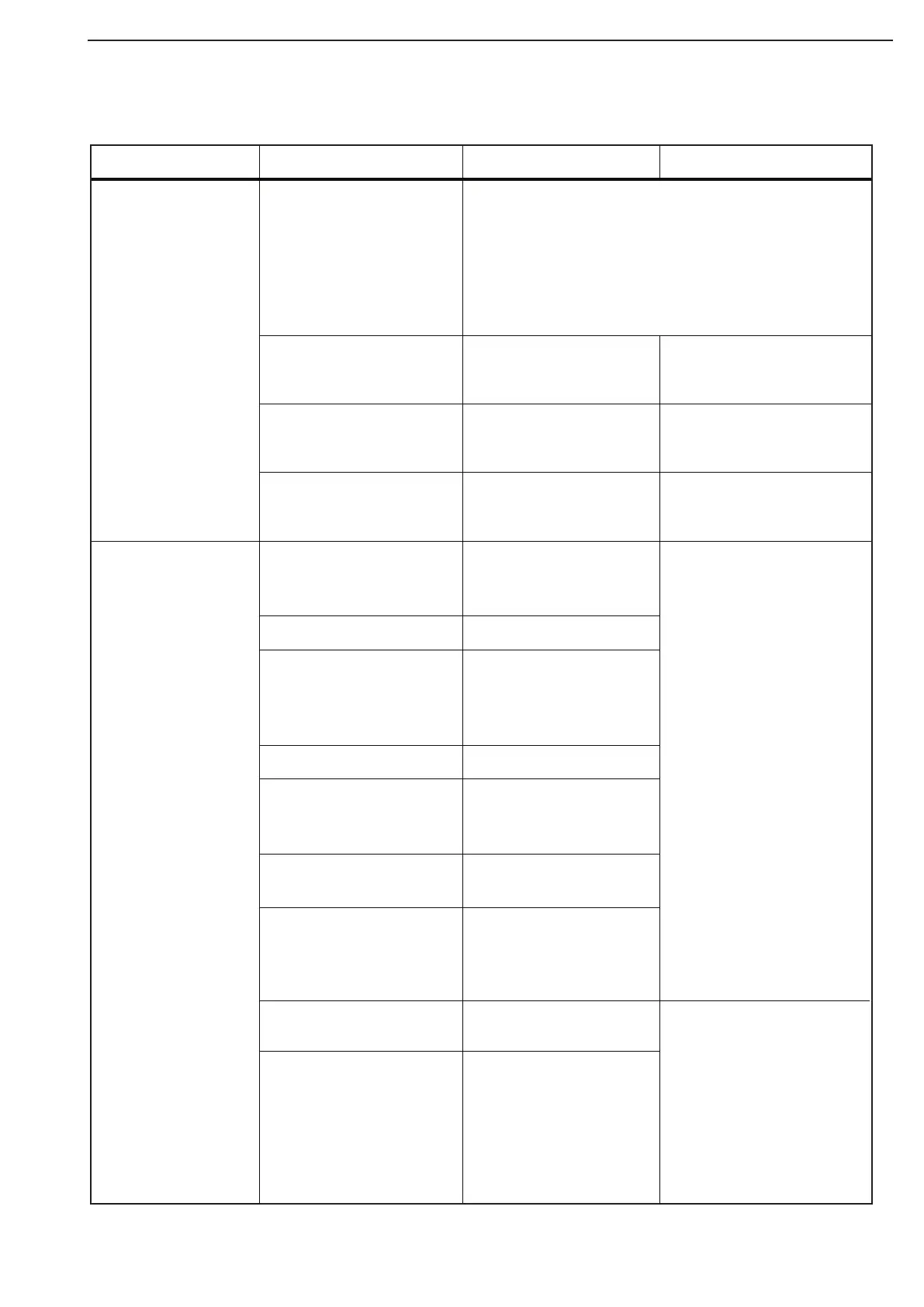

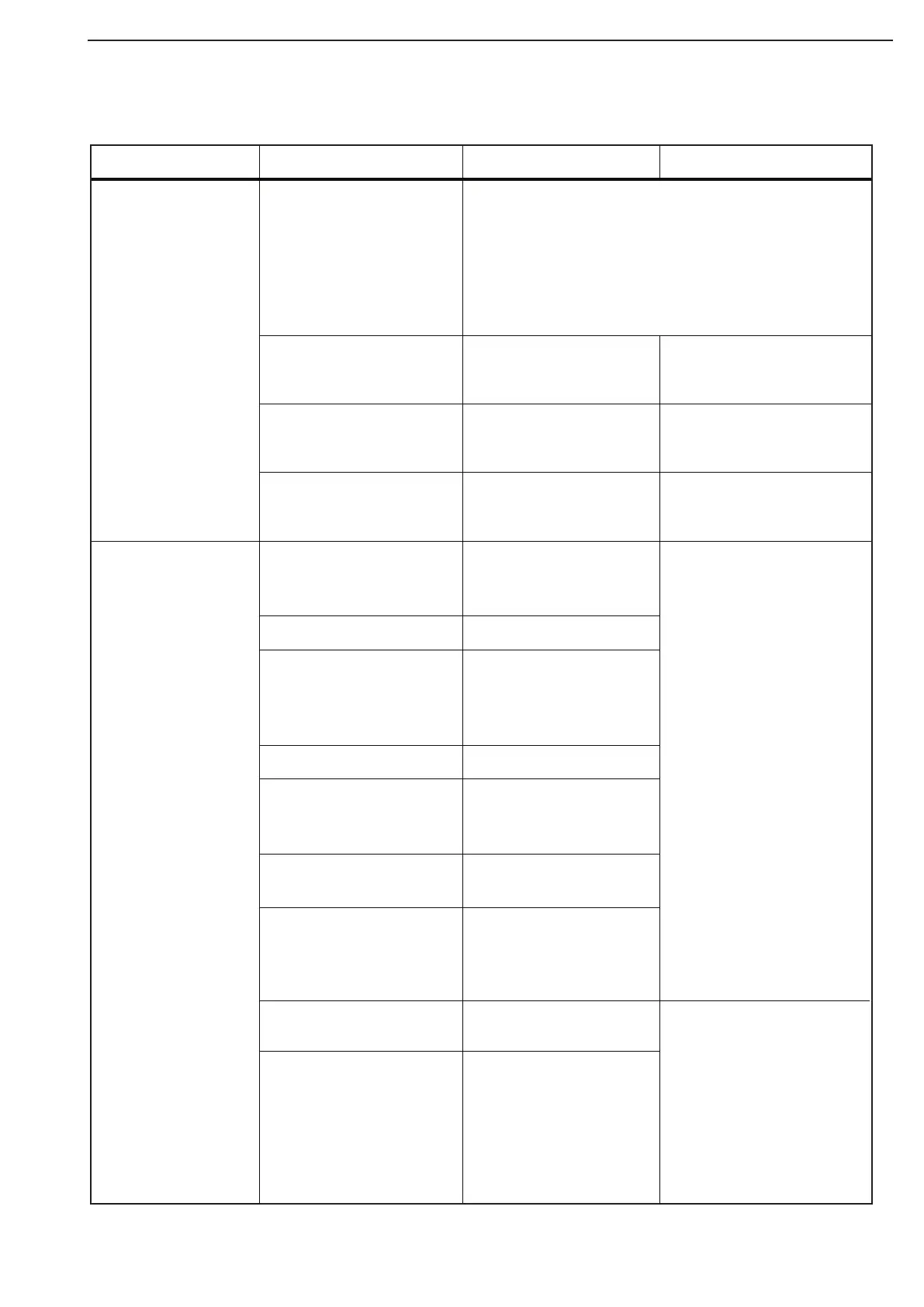

Low oil pressure

Eect Cause Trouble shooting Action

Gauge shows low

pressure

Defective sensor/instru-

ment

Take a reading of the oil pressure on warmed-up

engine using a mechanical pressure gauge directly

on the engine:

Minimum 1 bar at 800 r/min.

Maximum 6 bar > 800 r/min.

Obs! Single-speed engines must not be tested

at 800 r/min. Risk of damage to the exi -

ble coupling

Incorrectly adjusted oil

relief valve

- 1 shim = 0.2 bar

(screw adjustment on

14-series engines)

Broken spring in oil

relief valve (14-series

engines, earlier version)

Max. oil pressure 2 bar

at 2000 r/min

- Check/remedy

relief valve

The piston in the oil

relief valve has jammed

in open position

Gauge shows low

pressure

Loosened guide plates in

the oil cooler prevent

passage of the oil

Worn/damaged oil pump

Plug in cylinder block

under the relief valve

has come loose (11-

series engine)

Clogged oil cooler

Seized/worn bearings in

compressed air compres-

sor, see Compressed air sys.

Pressure varies when

compressor charges/

relieves

Loose screws in timing

gear’s intermediate gear

Gauge indicates low

pressure at maxi-

mum speed but not

at idling speed

The main oil duct (to

piston cooling nozzles)

plug in the rear of the

engine has come loose

(also at front of engine,

9-series engine)

Oil pressure at idling/

low engine speed is not

aected since the deliv-

ery valve closes at 3 bar

No oil pressure at

idling speed

(14-series engine)

Oil valve sleeve screwed

out of oil pump housing

(gives “by-pass” and

disables the overow

valve)

Check that the oil

valve sleeve is correctly

tted

- Tighten the oil valve

sleeve

- If damaged, change the

sleeve

Crankshaft bearing/main

bearing of wrong size

has been tted on

reground crankshaft

Max. oil pressure 2 bar

also when engine cold

- Change to bearings of

the correct size. Check

the bearing seats before

assembly

Excessive play in big-

end and main bearings

Seizing in camshaft

bearings

If the bushing slides all

the way out of the bear-

ing seat, the oil pressure

warning lamp will come

on.

The engine throws out

oil through the crank-

case ventilation

Piston cooling nozzle

has come loose

Seizing in the bearing on

engine power take-o

ED140 (14-series engine)

Oil pressure can be

increased ~ 1 bar when

the power take-o is

under load

Loosened oil duct plugs

at camshaft bearing

seats, under

the protection plate in

the V (14-series engine)

Pressure drops to 0 bar

Suction pipe to oil pump

has come loose, the

pump sucks air

Engine too hot

Extremely low lubricat-

ing oil viscosity

- Choose a viscosity that

is suitable for the ambi-

ent temperature

Worn bushings or loose

shaft in oil cleaner

- Change rotor if bush-

ing is worn oval

- Change worn/dam-

aged shaft

Broken O-ring on

cyclone part of oil

cleaner

Defective oil pump drive

Internal leakage in oil

cleaner

Ch

eck that the oil

cleaner is correctly

assembled

Loosened guide plates in

the oil cooler prevent

passage of the oil

Worn/damaged oil pump

Plug in cylinder block

under the relief valve

has come loose (11-

series engine)

Clogged oil cooler

Seized/worn bearings in

compressed air compres

sor, see also page

Pressure varies when

compressor charges/

relieves

Loose screws in timing

gear’s intermediate gear

Continuation next page

Loading...

Loading...