Engine

SHOP MANUAL

Ch 1 page 143

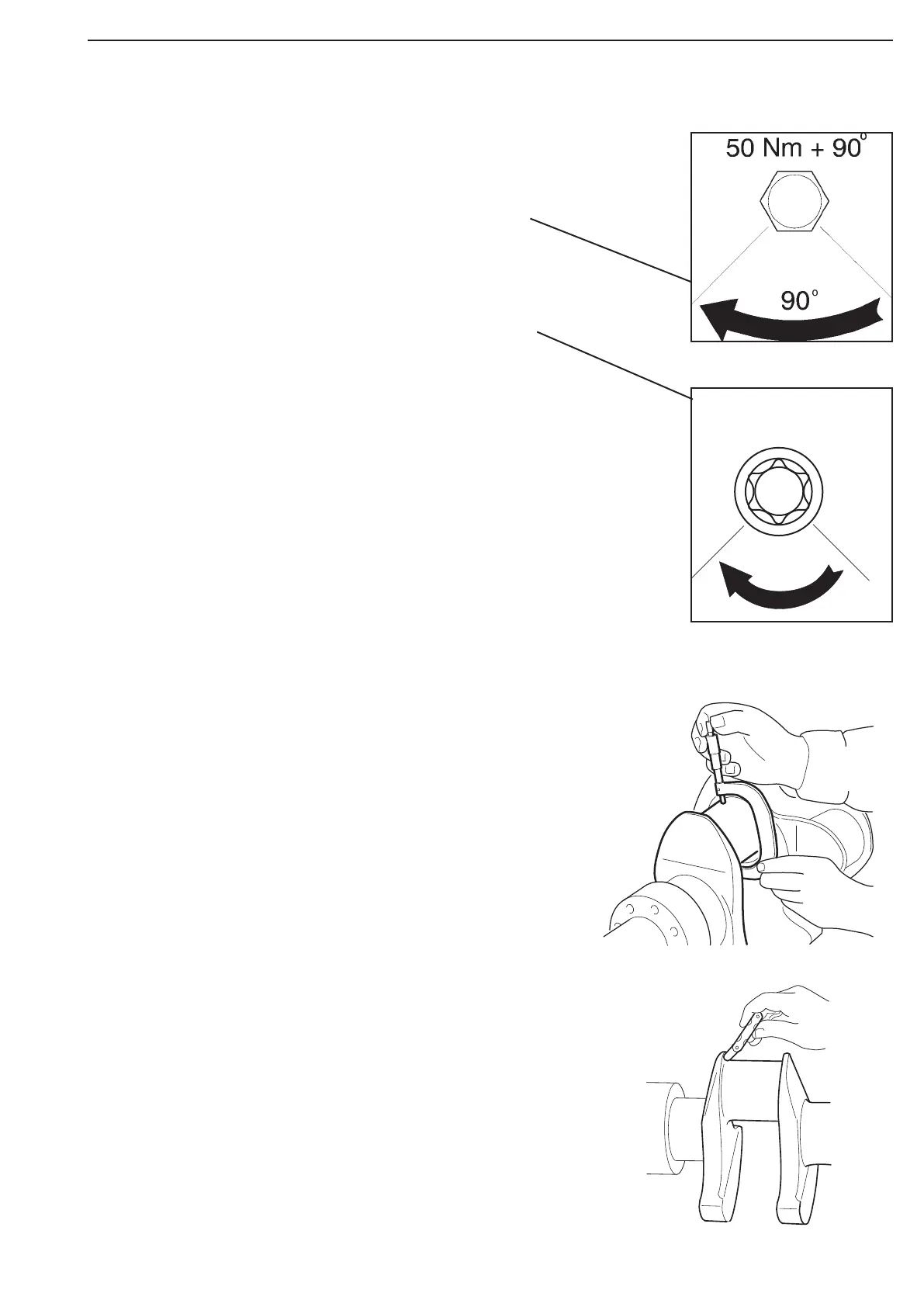

200 Nm +90°

90°

Figure 284

Figure 285

NOTE the machine serial number!

5.

Machine 810001 - 810108

Tighten the bearing cap bolts to 50 Nm

+ 90°.

5.

Machine 810109 (Tier3) -

Tighten the bearing cap bolts to 200 Nm

+ 90°.

6. Fit the pistons with connecting rods as

described in Fitting the connecting rod and

piston.

7. Fit the oil pump, oil suction pipe with strainer

and the oil sump.

8. Renew the seal in the front cover. Fit the

spacing sleeve on the crankshaft journal. Fit

the driver and crankshaft damper.

See Belt transmission, Renewing the seal in

the front cover.

9. Fit the crankshaft gear as described in

Crankshaft gear, fitting.

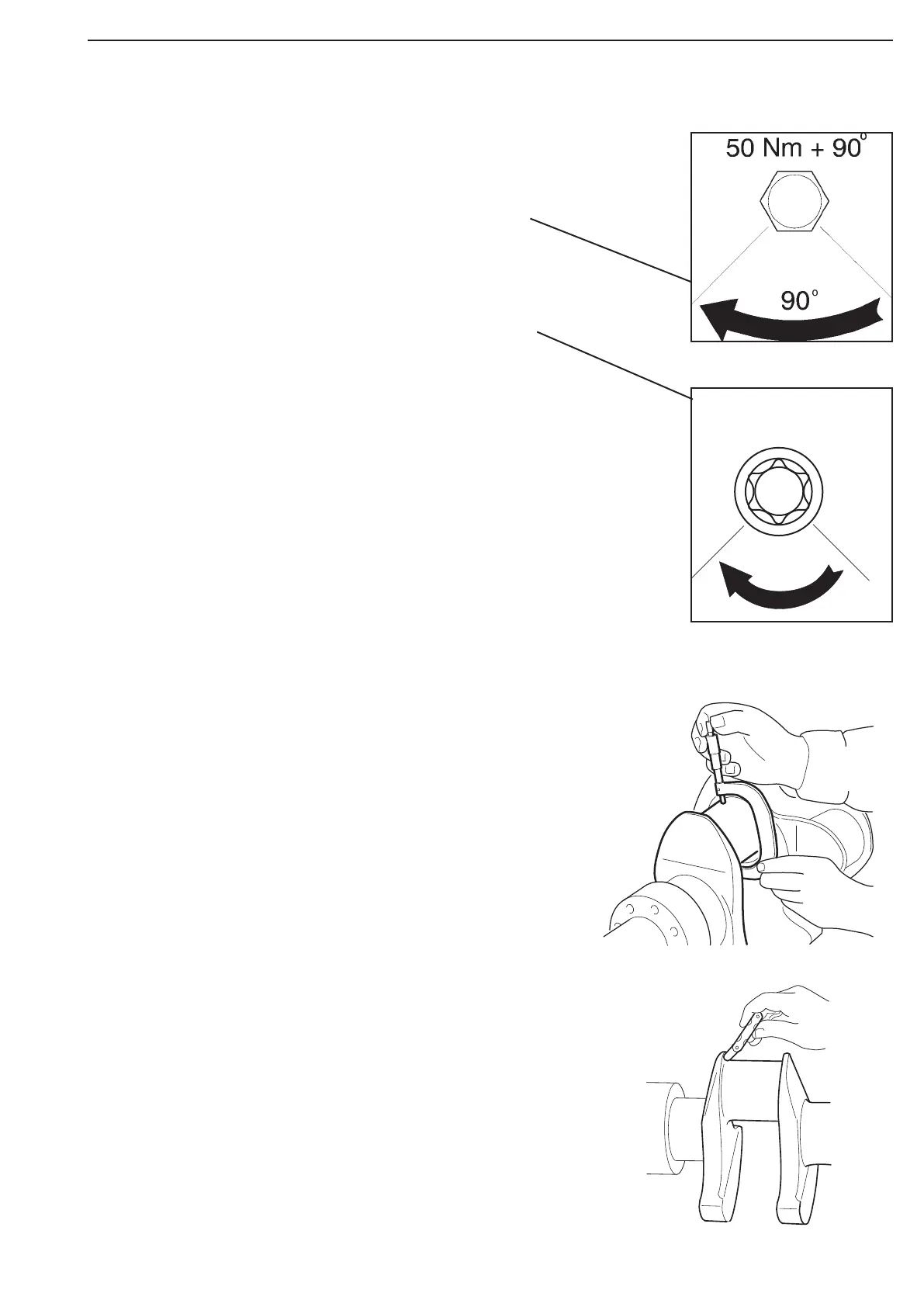

1. Measure the diameter of the crankshaft bearing journal using

a micrometer. Measure at several points around the bearing

journal.

If any of these diameters is lower than the minimum indicated

limit, regrinding of the crankshaft should be considered. Refer

to the dimensions under the tab “Specification”.

Oil pressure should also be checked, as it is affected by such

factors as wear in the main bearings and connecting rod bear-

ings.

2. When regrinding, keep to the undersizes indicated in the

“Specification” tab. Suitable bearings are available for these

sizes.

It is important that the fillet radius of the bearing journals is

correct. Use a template to check fillet radius.

Adjust - Machining the crankshaft

Figure 287

Figure 286

Loading...

Loading...