SHOP MANUAL

Engine

Ch 1 page 102

Assembling piston and connecting rod

1. Clean the piston and its rings thoroughly

without scratching the sides of the ring

grooves. The oil holes in the piston should be

cleaned using a suitable drill.

2. Make sure the piston ring gaps do not exceed

the permitted limit.

Place the piston rings in the cylinder liner

and measure the gap using a feeler gauge.

For permitted gap, see section entitled

Specifications, piston rings.

Make sure the piston ring gaps do not exceed the permitted limit.

Place the piston rings inside the cylinder liner and measure the

gap with a feeler gauge. Permitted gap according to values listed

below.

Maximum piston ring gap for 9 and 13 litre engines with XPI:

Compression ring 1 (upper) 0.9 mm

Compression ring 2 (lower) 1.1 mm

Oil scraper ring 0.8 mm

Maximum piston ring gap for 9 and 13 litre engines with PDE:

Compression ring 1 (upper) 0.9 mm

Compression ring 2 (lower) 1.8 mm

Oil scraper ring 0.8 mm

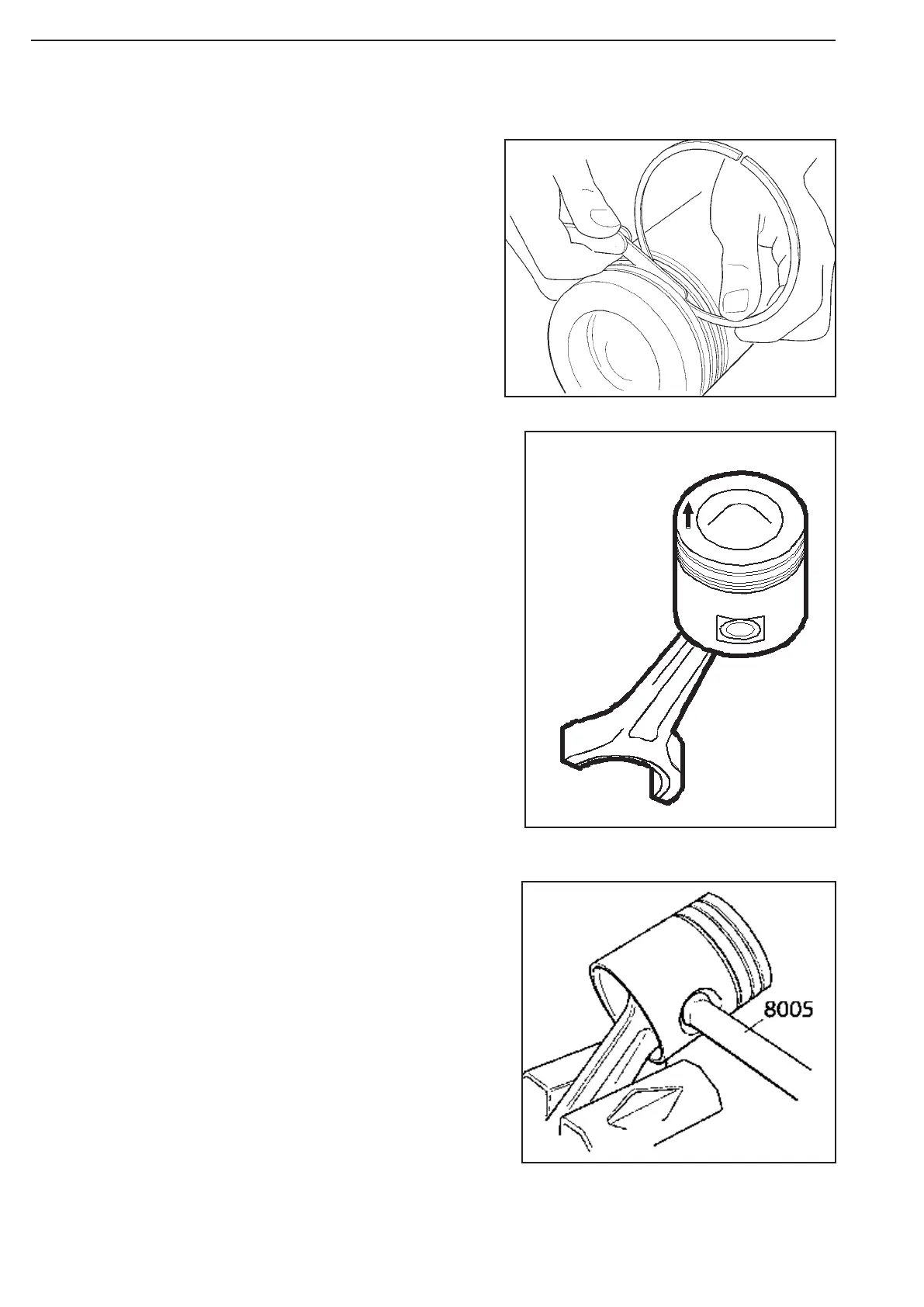

3. Fit the piston rings using tool 8395. The

oil scraper ring has an expander. Pistons

rings marked with TOP must be turned with

TOP face up.

4. Oil all the bushings, the gudgeon pin hole

and the gudgeon pin before assembling.

5. Place one of the retaining rings in the piston.

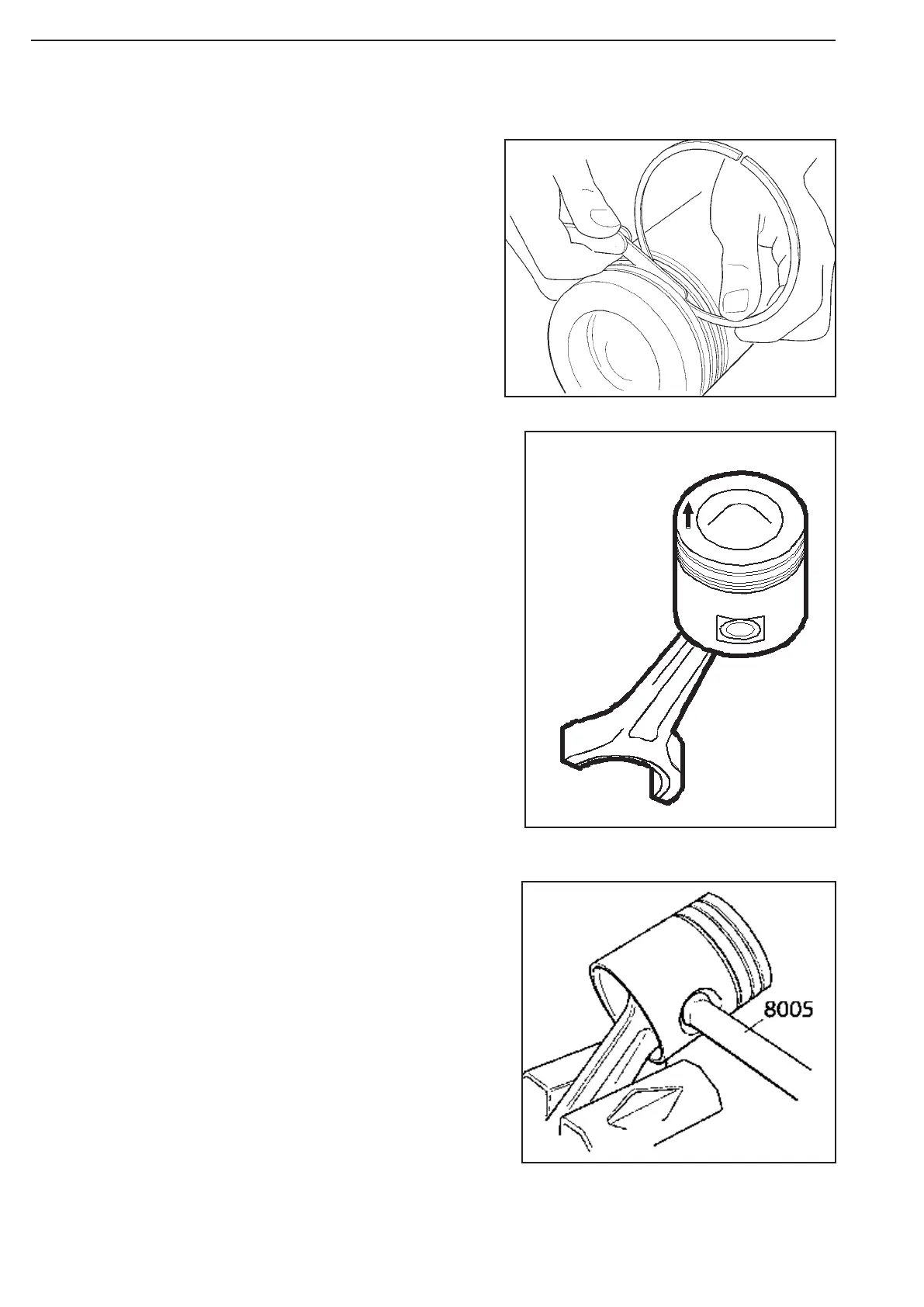

6. Turn the piston and connecting rod as

illustrated. The arrow mark should point

forward on the engine.

7. Insert the gudgeon pin using tool 8005 and

fit the second retaining ring for the gudgeon

pin.

Figure 195

Figure 196

Figure 197

Loading...

Loading...