Ch 6 page 29

ELECTRICAL SYSTEM

SHOP MANUAL

Always wear eye and hand protection when working on an A/C system or compressor. Liquid

refrigerant can cause frostbite and / or blindness.

Do not discharge R134a into the atmosphere. Even though its ozone

depletion potential is zero, it does have global warming potential. Re-

covery and recycling are mandated by the clean air act. Use recovery

equipment designated only for R134a. Never introduce another

refrigerant into the R134a equipment.

WARNING

R134a gas properties:

Solid phase - Melting point: 1.1013bar -101°C

Liquid phase - Liquid density: (1.013bar and 25°C) 1206kg/m³

Boiling point: (1.013bar) : -26.55°C

It’s imperative to install a new lter receiver drier after opening of the air conditioning circuit !

WARNING

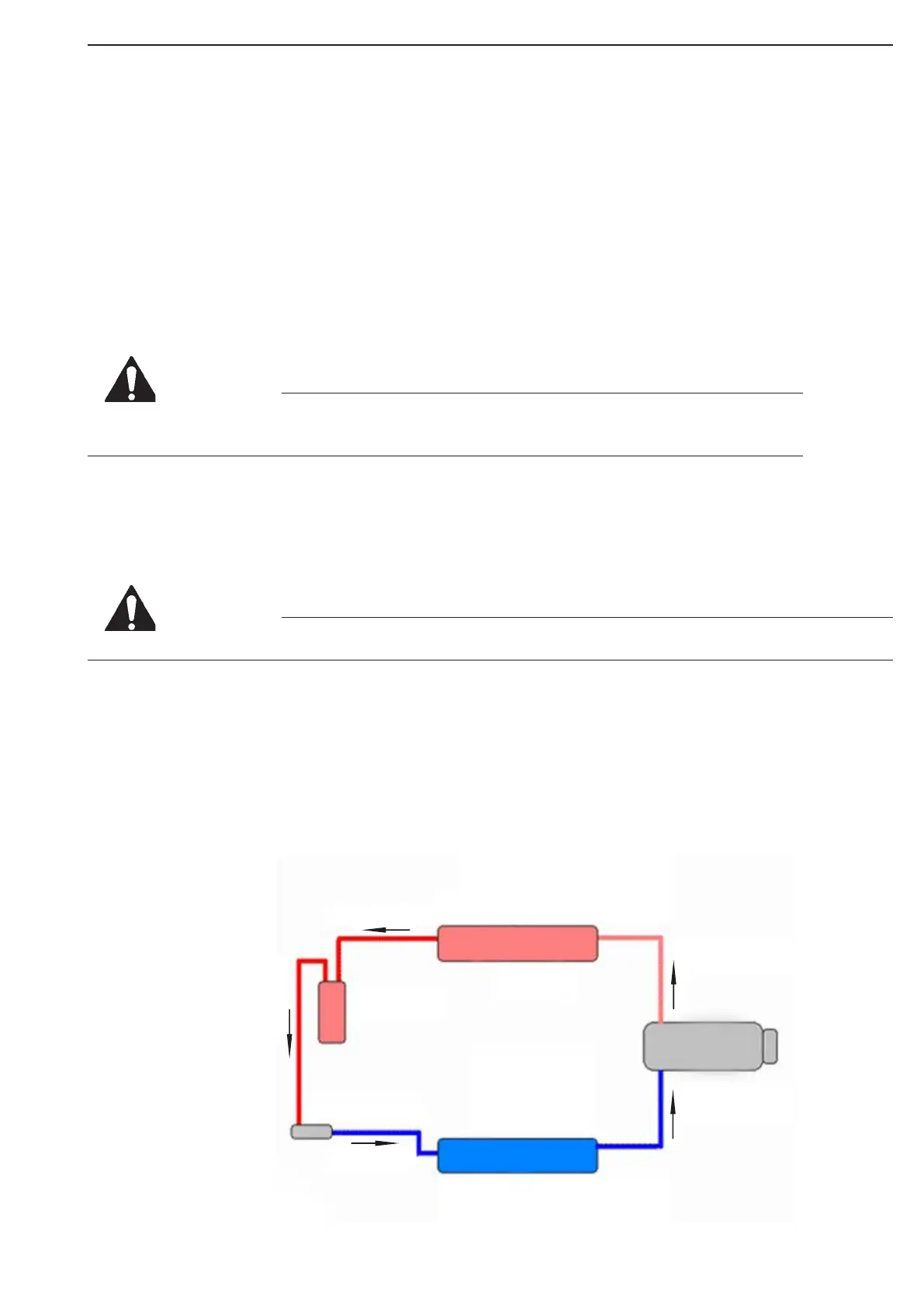

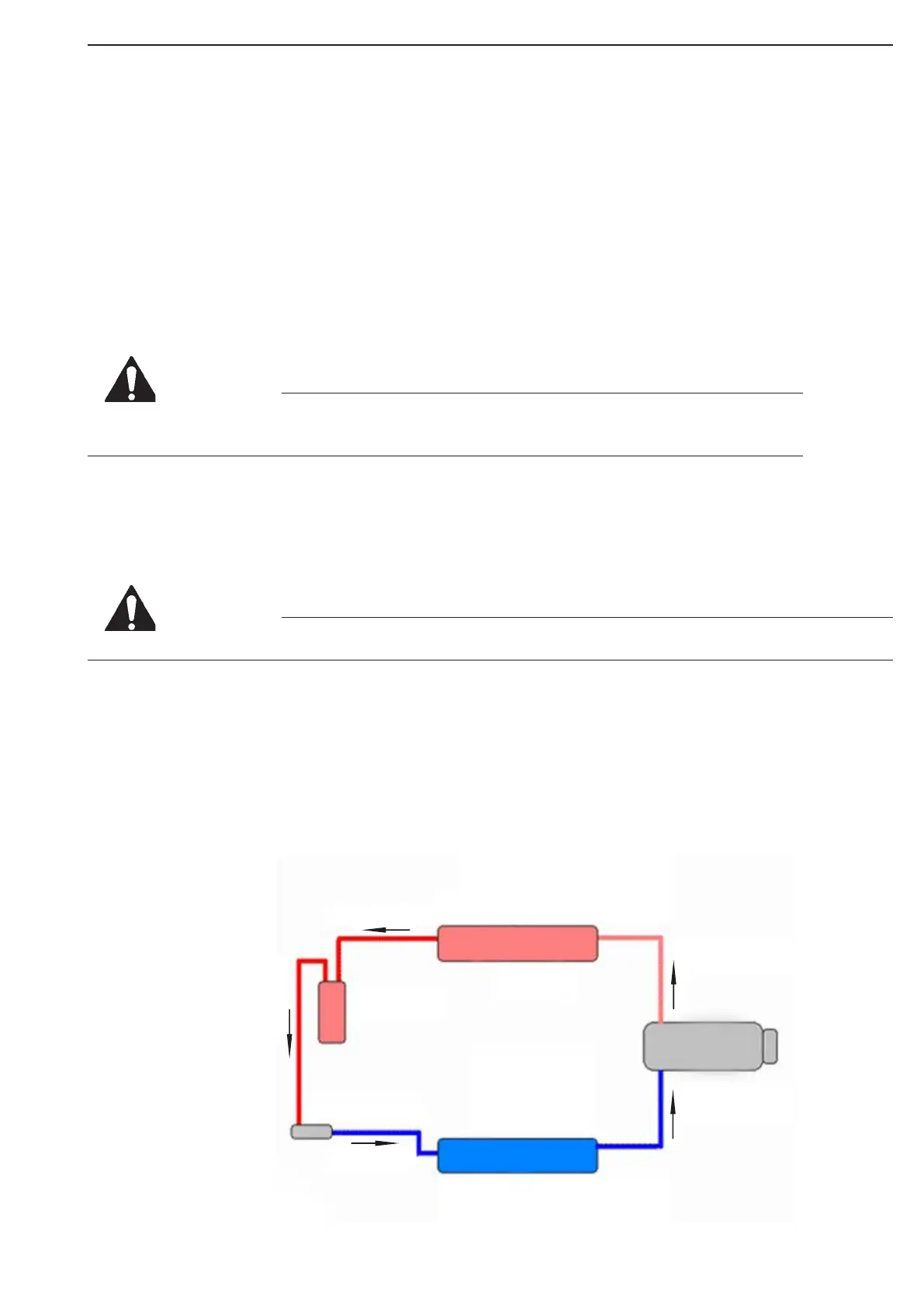

Liquid phase

Receiver/drier

Expansion valve

Liquid phase inlet

Evaporator

Vapour phase

Compressor

Vapour phase

Condenser

Vapour phase outlet

Liquid phase

Regulation controll

Prior to the inspection:

• Check that the air inlets are not blocked by any residues.

• Check that the cab air louvers are opened to avoid evaporator freeze.

• With the automatic slack adjuster, check the compressor drive belt movement and ten-

sion: A too high tension: early wearing of the compressor bearings

A too low tension: early wearing of the belt

AIR CONDITIONING CONTROL

Commands must be set as follows:

· Air recirculation at maximum

· Temperature setting at minimum

· A/C symbol ON

Loading...

Loading...