SHOP MANUAL

Ch 6 page 30

ELECTRICAL SYSTEM

For a new compressor to be used in this type of system,

subtract the delivered oil amount from the desired total

oil charge to determine how much oil should be added to the com-

pressor and system.

Remove the oil filler plug and charge the compressor with the

amount of additional oil determined in previous picture. Use only

new oil of the correct type as shown on the compressor label. If cal-

culated amount is greater than 300cc (10oz) oil can be added

to other system components.

Repair

If a repair is performed on an R134a compressor or system, evacu-

ate the system for at least 30 minutes before recharging to ensure the

removal of moisture which may have been absorbed by the PAG oil in

the compressor and system.

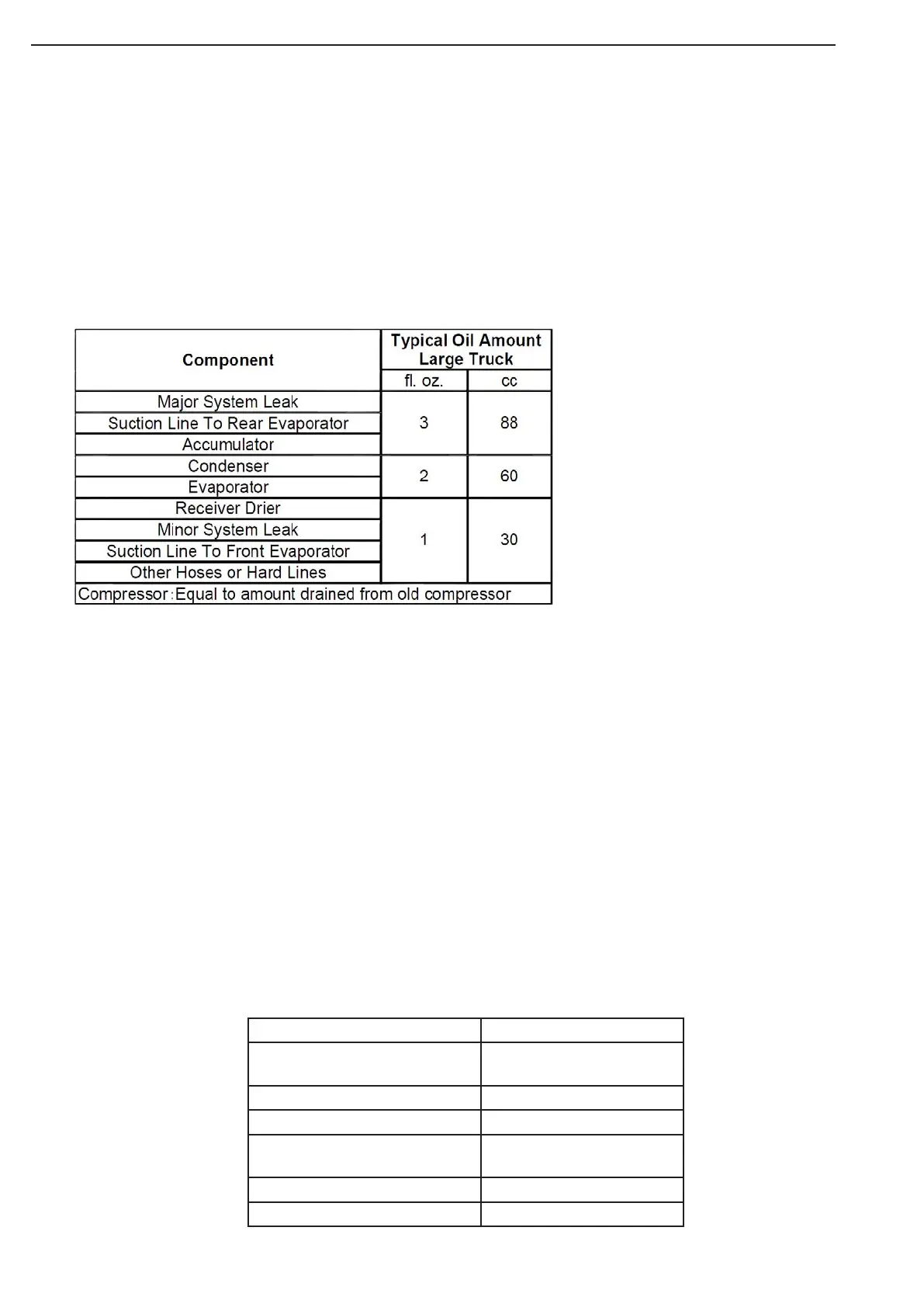

Oil replacement amount during service:

When replacing a system component the goal is to restore to the

original factory amount. This can be found on compressor label. Use

the chart below as a guide for restoring oil quantities when replacing

system components.

Figure 21

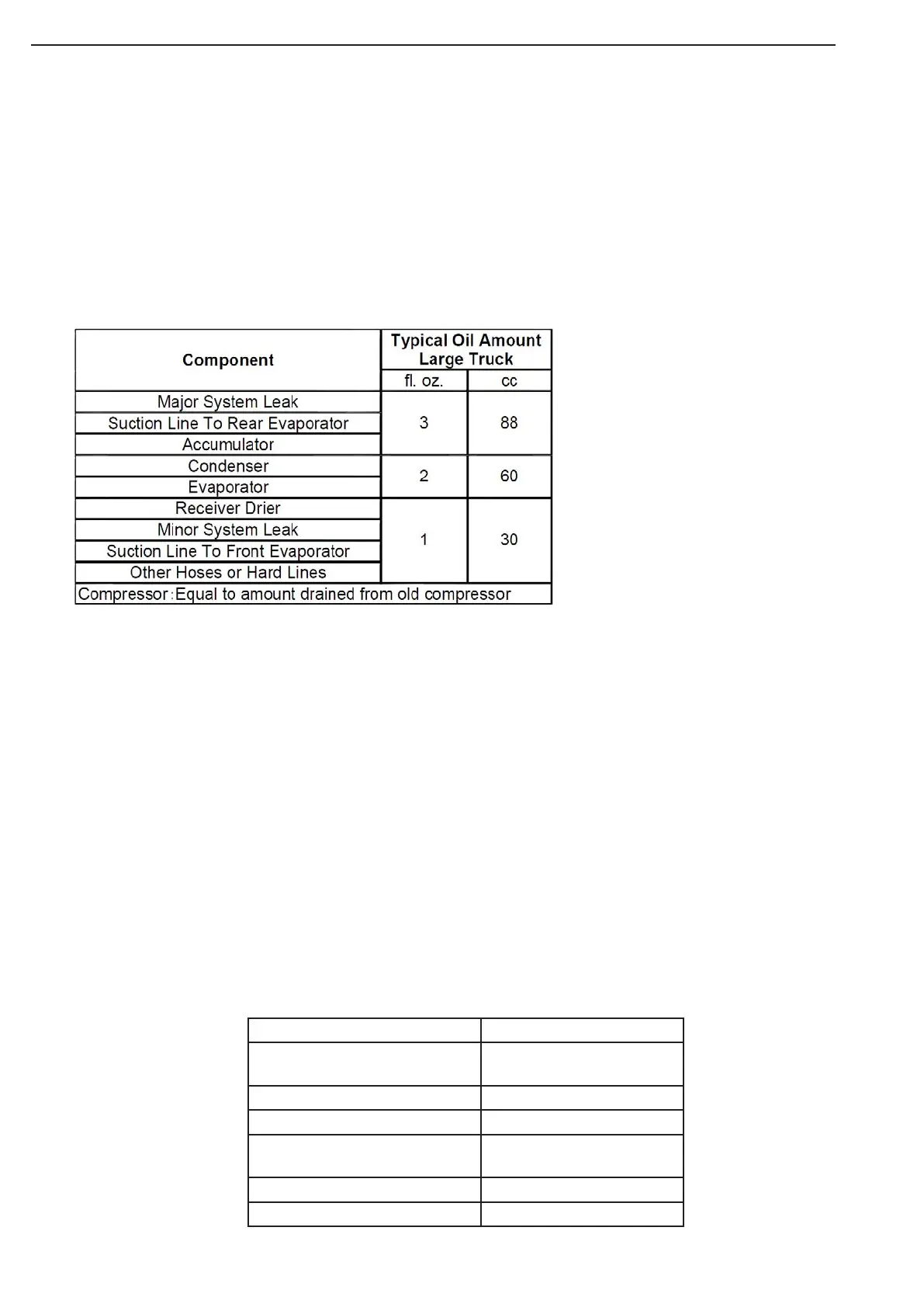

Fitting Torque

Discharge compressor 15.4Nm

Suction compressor 24.4Nm

Inlet condesnsor 15.4Nm

Outlet condensor and

filter drier

15.4Nm

Inlet evaporator 15.4Nm

Outlet evaporator 24.4Nm

To avoid damage or leaks to connections:

Unscrew the fitting of screw using a torque wrench and a back-up spanner

Always use the torque wrench on the fitting that is being tightened, and set it to

the specified torque for each fitting size.

Loading...

Loading...