SHOP MANUAL

Engine

Ch 1 page 138

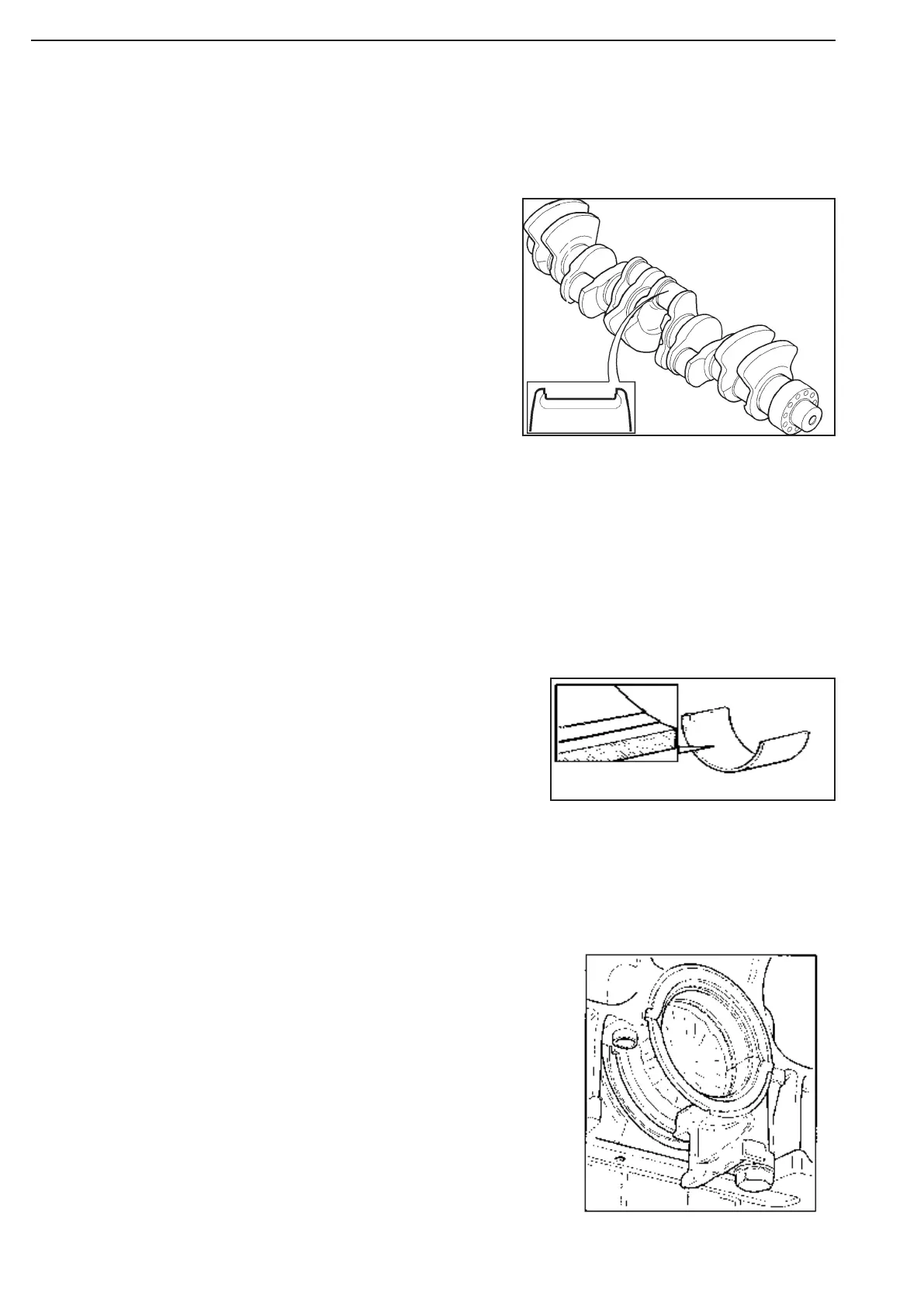

Each compression stroke ”brakes” the crankshaft and each com-

bustion stroke attempts to increase the speed of rotation of the

crankshaft.

The pistons and connecting rods change their direction of travel

twice during each rotation of the crankshaft. This exposes the

crankshaft to numerous power pulses during each revolution.

The material is of major importance for the useful life of the crank-

shaft. Its design and surface treat ment also help to extend its life

- for instance, the surface quality of the shaft journals is an impor-

tant factor in providing protection against fatigue failure.

The bearing surfaces on the crankshaft are hard ened to a depth

which allows them to be ground several times.

Only the bearing surfaces are hardened as it is important to retain

the toughness of the material in other parts.

Crankshaft

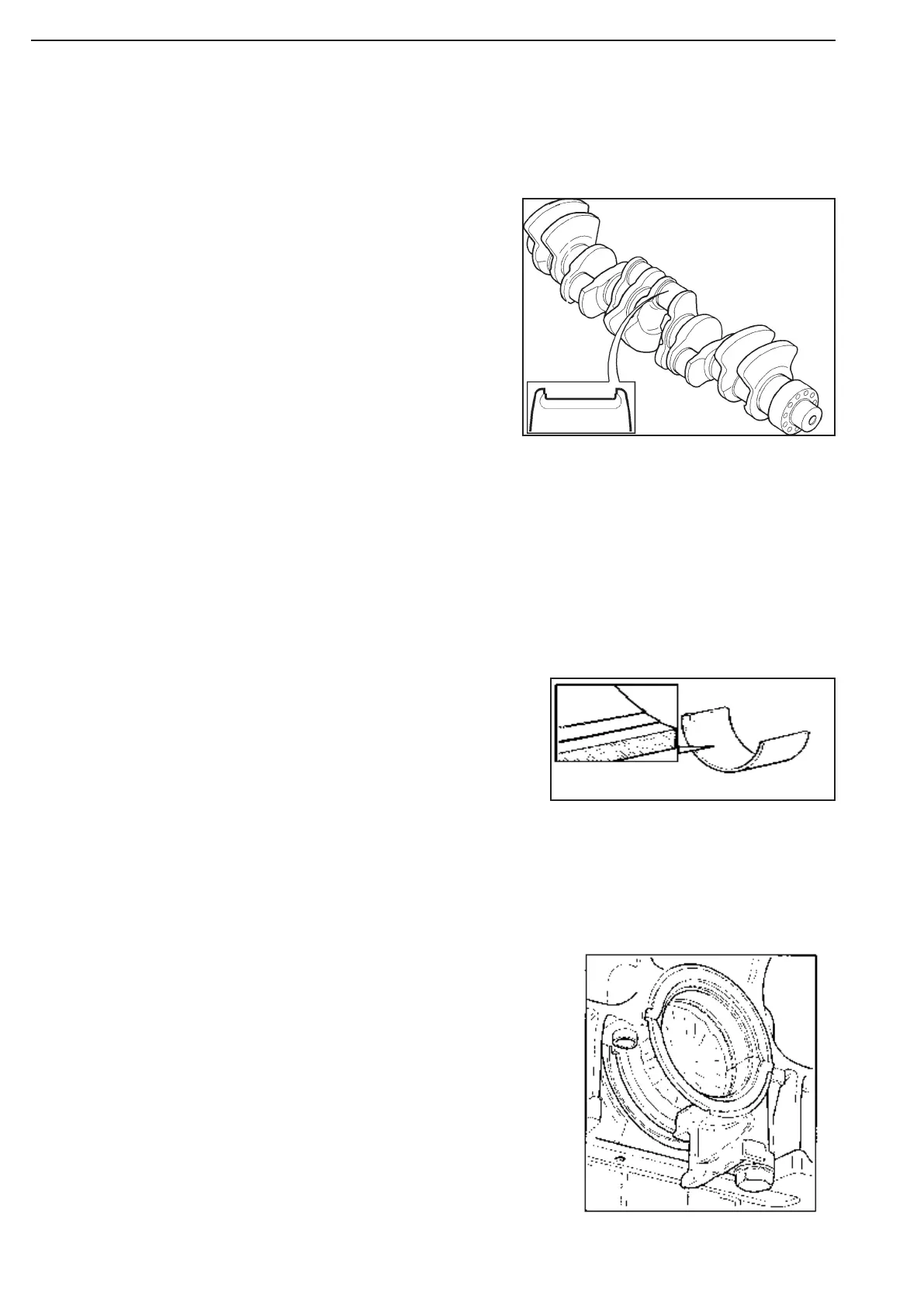

The bearing shells of the main and big-end bear ings consist of

three layers. An outer layer or backing of steel, an interlayer of

lead-bronze and, nearest the crankshaft, an overlay consisting

of a mixture of lead and indium or lead, tin and cop per. The in-

nermost layer is usually worn away during the course of engine

utilization.

Thrust washers are used for endways location of the crankshaft

at the rear main bearing. These thrust washers are available in

different thick nesses so that the crankshaft can be adjusted to

the correct clearance. The thrust washers have the same types

of layer as the big-end bearing shells.

Figure 274

Figure 275

Figure 276

Loading...

Loading...