SHOP MANUAL

Engine

Ch 1 page 140

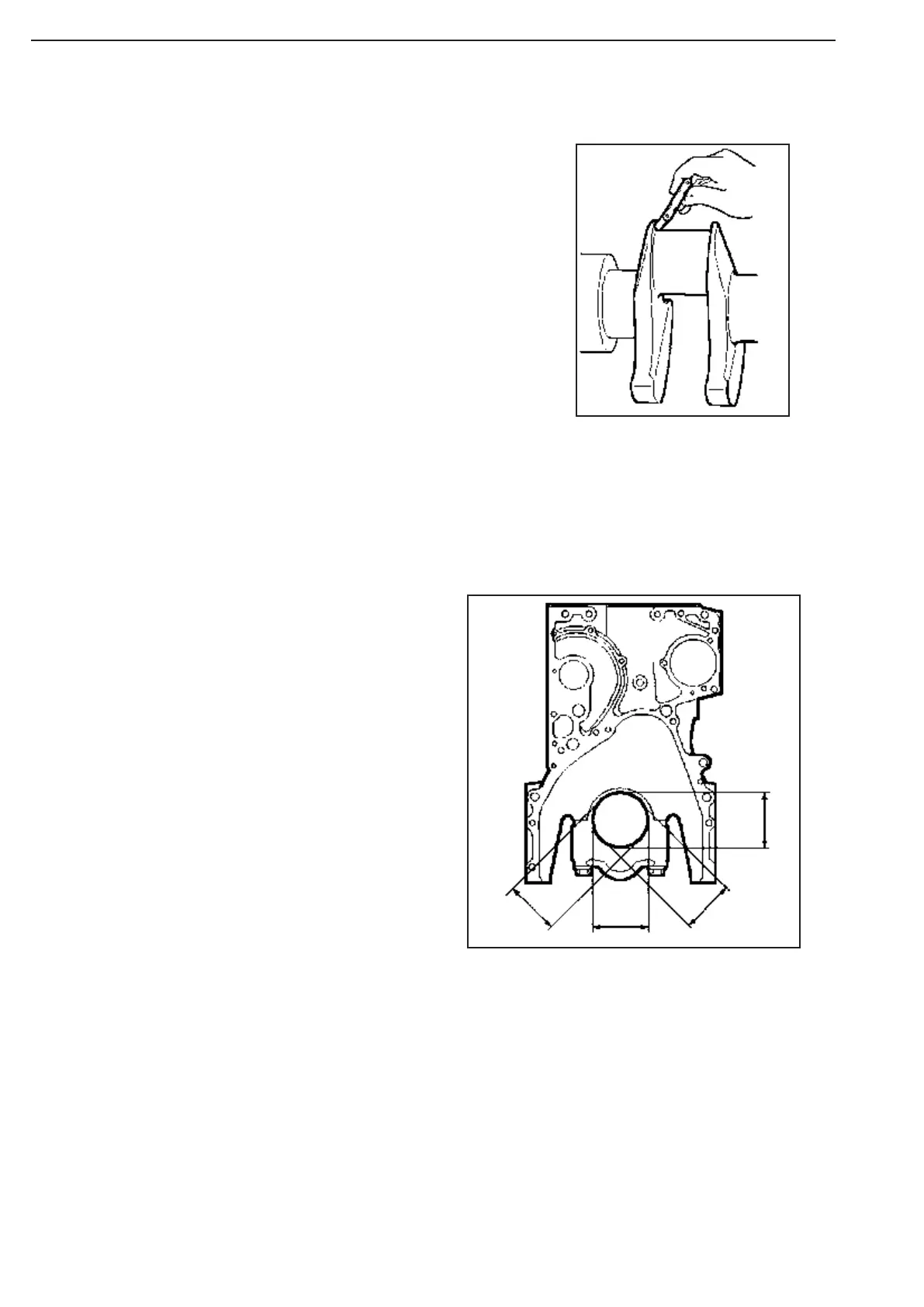

- When regrinding, stated undersizes must be

complied with. Suitable bearings are

available for these sizes.

- Refer to the next page for the diameters

required for different undersizes.

- It is important that the fillet radius of the

journals is correct.

- After grinding the journals, the oil hole

connections to the bearing surfaces should be

rounded off and polished.

Cylinder block

Reconditioning

Heat arising from the main bearings seizing and

rotating in the cylinder block will change the

properties of the material in the cylinder block.

These cylinder blocks must be discarded.

If the main bearing seizes but does not rotate in

the cylinder block, the cylinder block can be

overhauled. The main bearing seats must

comply with the demands on roundness given in

the table. Machining out-of-round main bearing

seats is something we do not recommend.

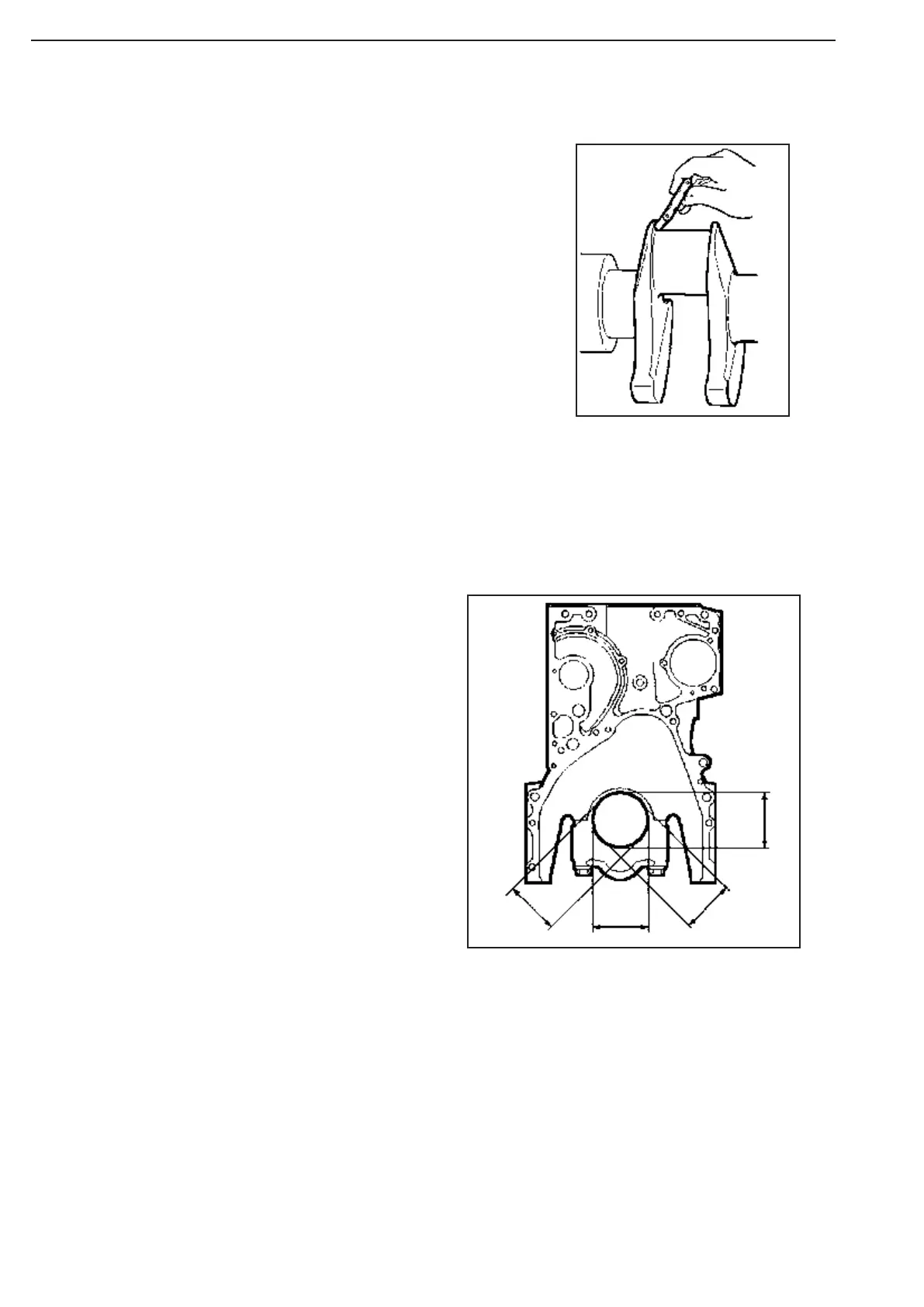

1. Measure the diameter at four different

positions as illustrated. The diameter must

be measured with the main bearing caps

tightened and without main bearings.

2. Check the dimensions with those in the

table.

Minimum Maximum Maximum

permitted permitted permitted

diameter diameter difference*

112.200 mm 112.222 mm 0.016 mm

* Maximum permitted difference between the largest

and smallest diameter on the same main bearing

seat.

Figure 279

Figure 280

Loading...

Loading...