Engine

SHOP MANUAL

Ch 1 page 215

Important !

After renewing an injector with internal leakage, the engine oil must be changed and the oil filter renewed. If

there is internal leakage, soot quickly builds up in the engine oil. (For fluid type and specifications, refer to the

DOOSAN Operating & Maintenance Manual Chapter 6)

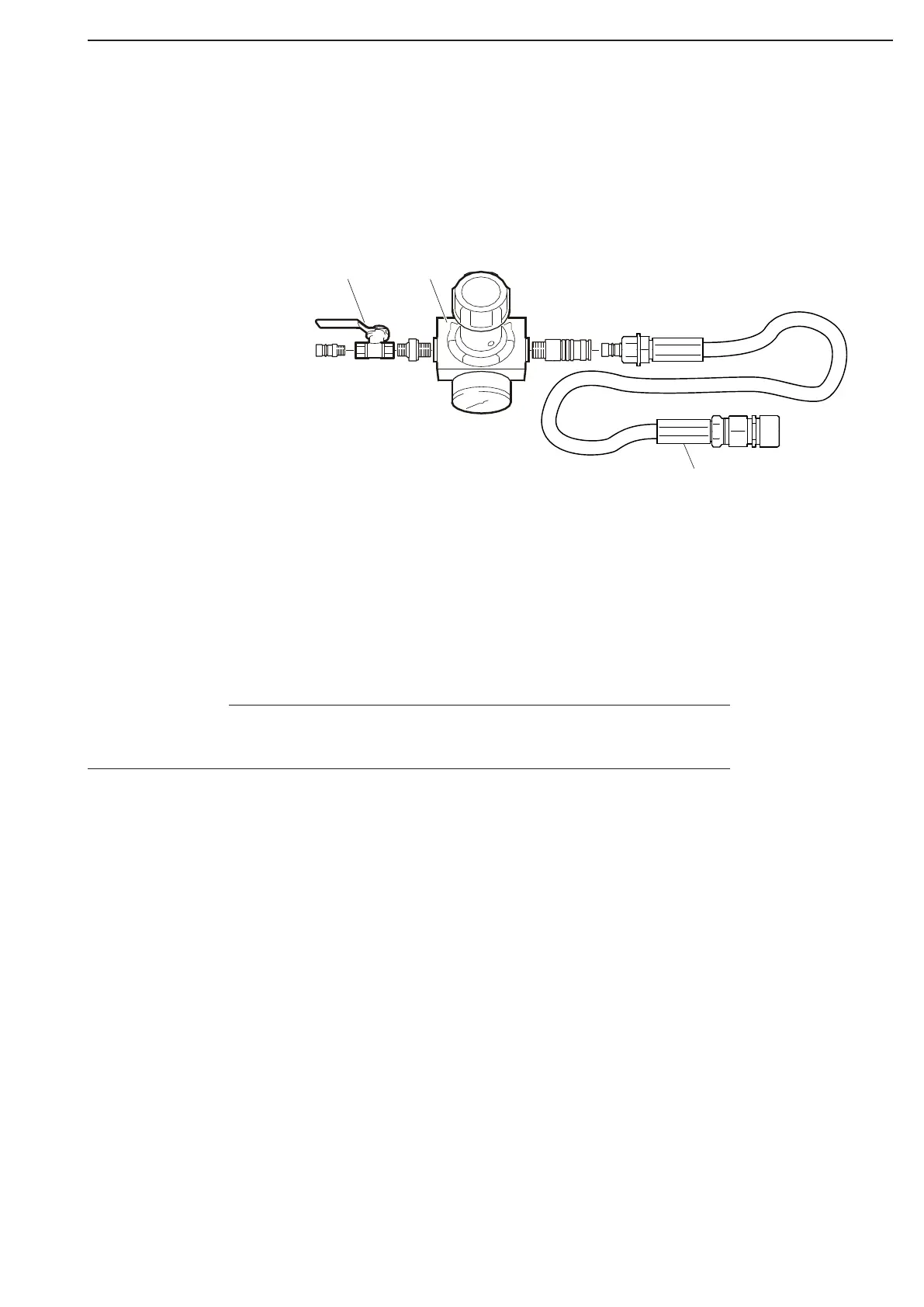

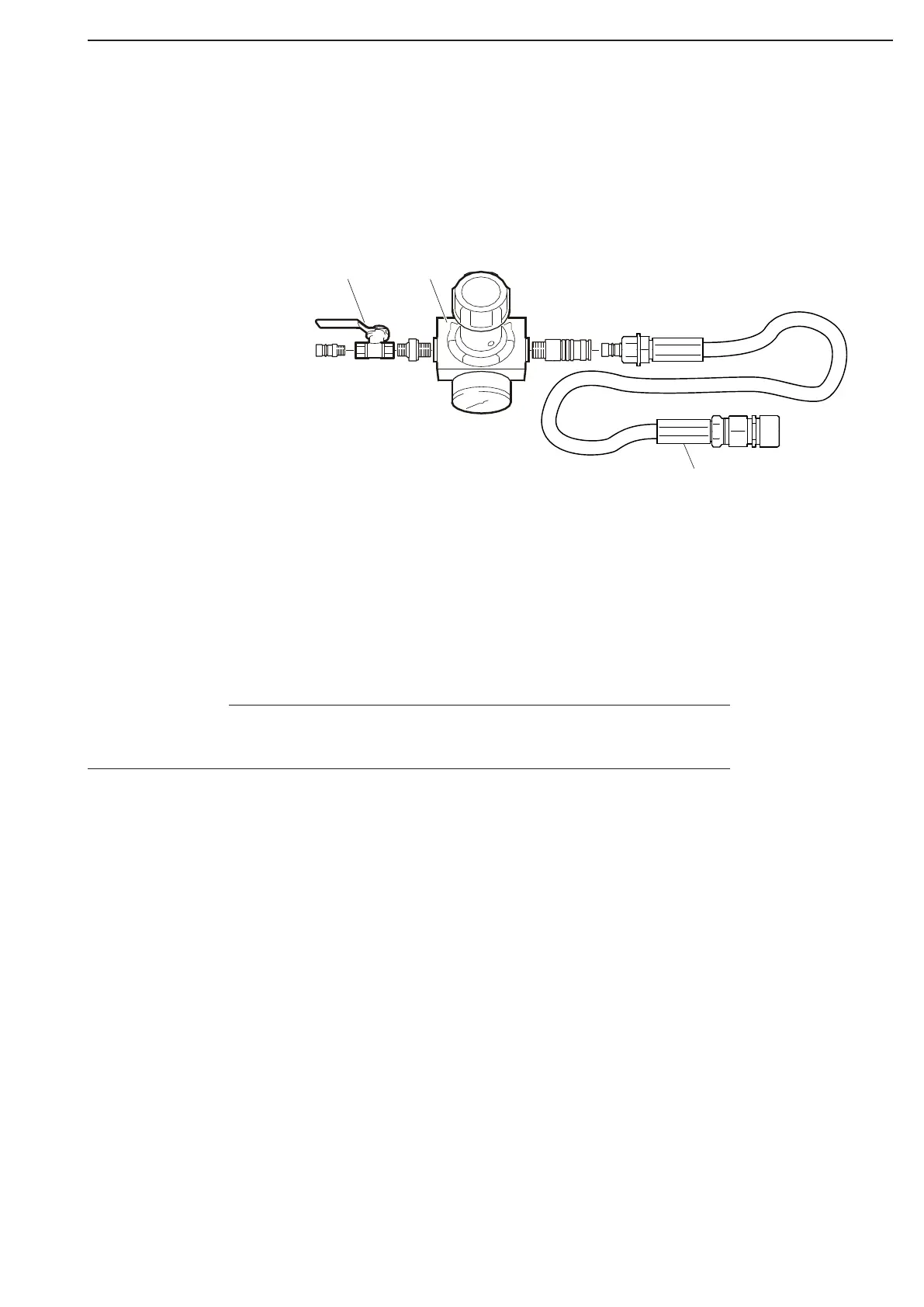

Tools for test pressurising the fuel system

A - Shut-off valve

B - Pressure regulator

C - Hose for connection to the fuel system

H7 – Checking the return fuel pressure

1. Connect pressure gauge 99 362 to the test connection on the return fuel manifold and open the test

connection.

2. Crank the engine using the starter motor. Read the pressure after approximately 20 seconds. The pressure

should be below 0.8 bar.

3. If there is no detectable value after 20 seconds, let the starter motor cool and repeat step 2.

4. Remove the pressure gauge and close the test connection.

H8 – Checking the safety valve

1. Remove the return line from the safety valve to the return fuel manifold so that it vents straight out into the

atmosphere.

2. Crank the engine using the starter motor. If fuel leaks out of the safety valve, it is faulty and must be

renewed.

3. Refit the engine pipes. Torque tighten.

H9 – Checking the high pressure pump

1. Check the cylinder head on the high pressure pump as described in the workshop manual, see section

03-00 Fuel system Scania XPI. If a fault is detected, then renew the cylinder head.

2. If the cylinder head is OK or if there are still problems, it may be due to a defective fuel inlet metering valve.

Try fitting a new fuel inlet metering valve.

3. If the problem still persists, the problem may be in the high pressure pump. Renew the high pressure pump

and continue to S-a to confirm.

A B

C

If there is air in the lter housing, pressure cannot build up. Vent the lter housing

and try again.

NOTE

Figure 385

Loading...

Loading...