Engine

SHOP MANUAL

Ch 1 page 219

IMPORTANT!

After renewing an injector with internal leakage, the engine oil must be changed and the oil filter renewed.

If there is internal leakage, soot quickly builds up in the engine oil. (For fluid type and specifications, refer to the

DOOSAN Operating & Maintenance Manual Chapter 6)

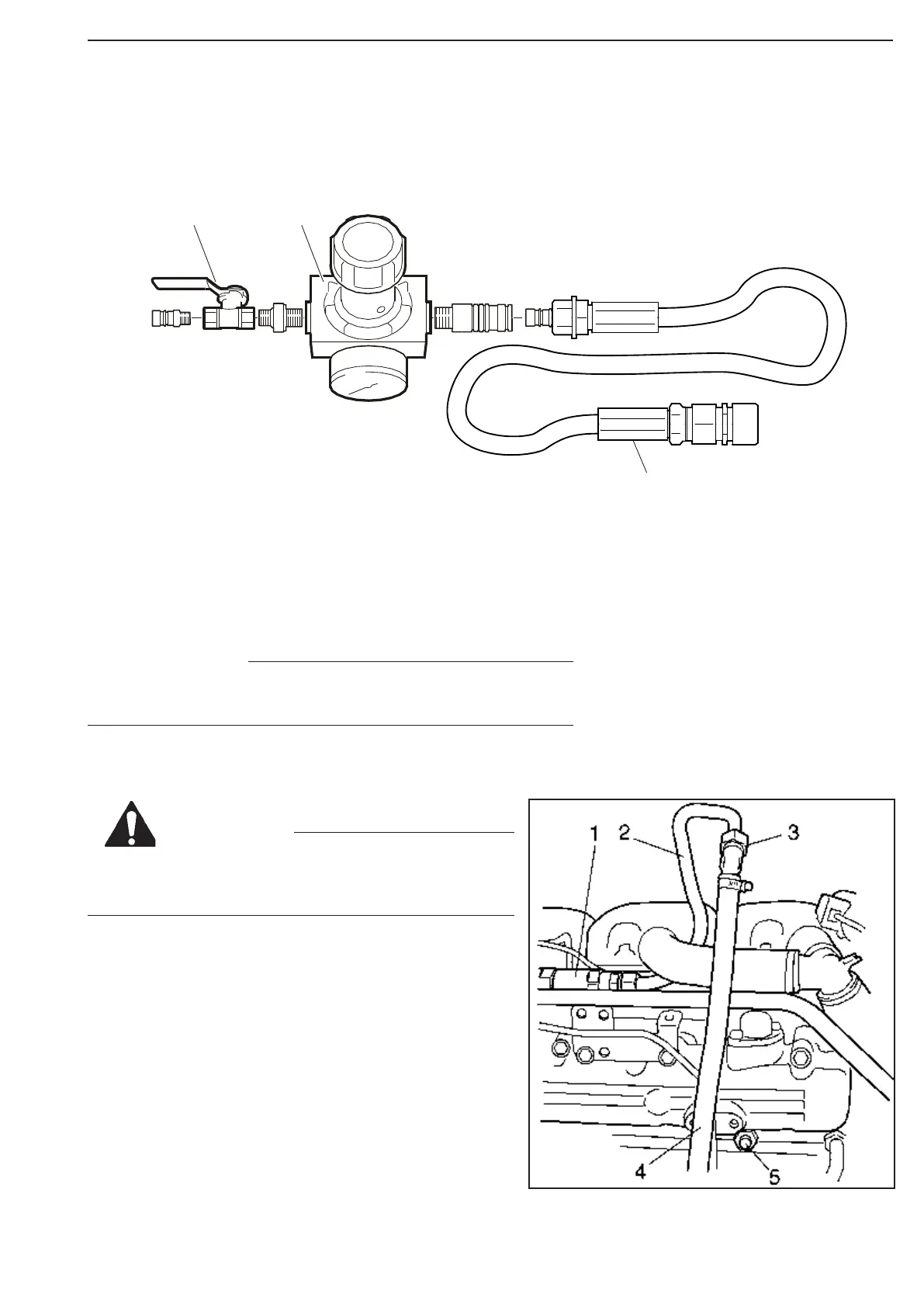

Tools for test pressurising the fuel system

A - Shut-off valve

B - Pressure regulator

C - Hose for connection to the fuel system

H7 - Checking the return fuel pressure

1 Connect pressure gauge 99 362 to the test connection on the return fuel manifold and open the test

connection.

2 Turn the engine over using the starter motor. Read the pressure after approximately 20 seconds. The

value should be below 0.8 bar.

3 if there is no detectable value after 20 seconds, let the starter motor cool and repeat step 2.

4 Remove the pressure gauge and close the test connection. H7 - Checking the return fuel pressure

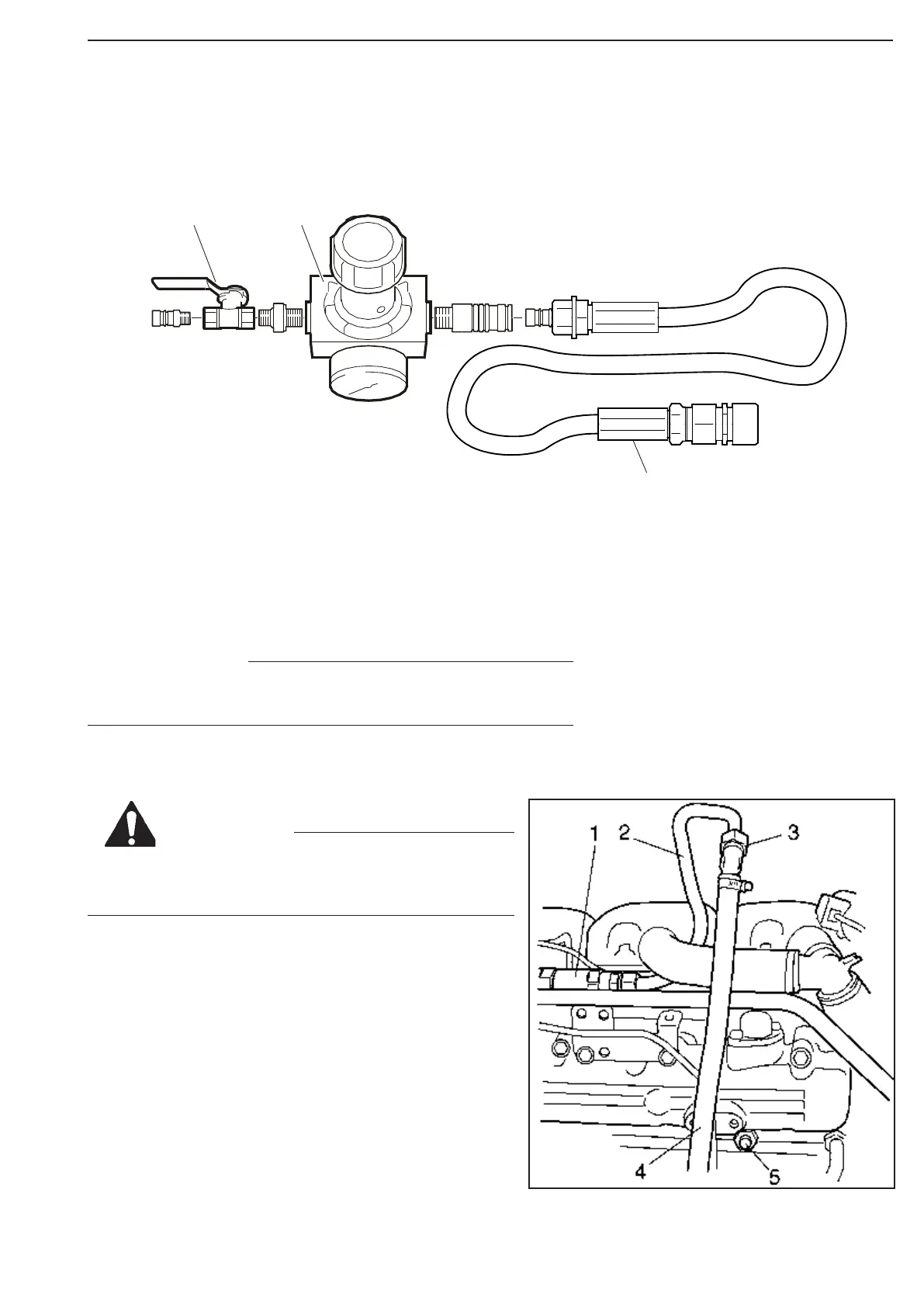

H8 - Checking the safety valve

1 Remove the return pipe 2 from the safety

valve 1 to the return fuel manifold 5.

2 Plug the connection in the return fuel manifold

with cap nut 812 890 or 814 555 and

sealing plug 813 878.

3 Refit the return pipe at a slight angle to the

engine. Connect a transparent hose 4 to a union

3 - 366 082 on the pipe. Pull the hose down into

a can or similar.

4 Turn the engine over using the starter motor.

If fuel leaks out of the safety valve, it is faulty

and must be replaced.

5 Refit the engine pipes. Torque tighten.

If there is air in the lter housing, pressure cannot build up. Vent

the lter housing and try again.

The accumulator may be under high pressure. Re-

duce the pressure using SDP3 before starting work.

Wear protective goggles.

NOTE

WARNING

Figure 388

Figure 387

Loading...

Loading...