Engine

SHOP MANUAL

Ch 1 page 29

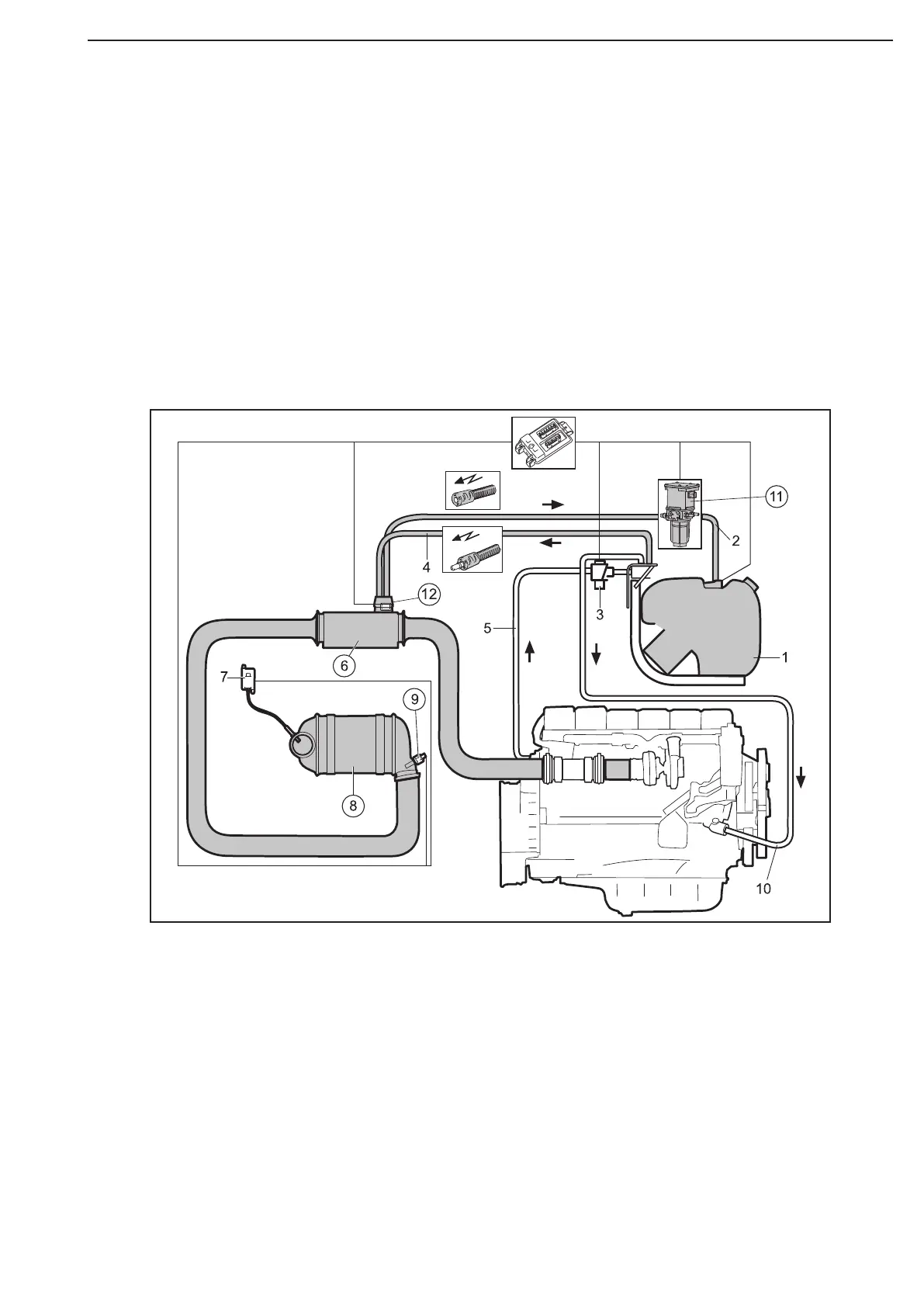

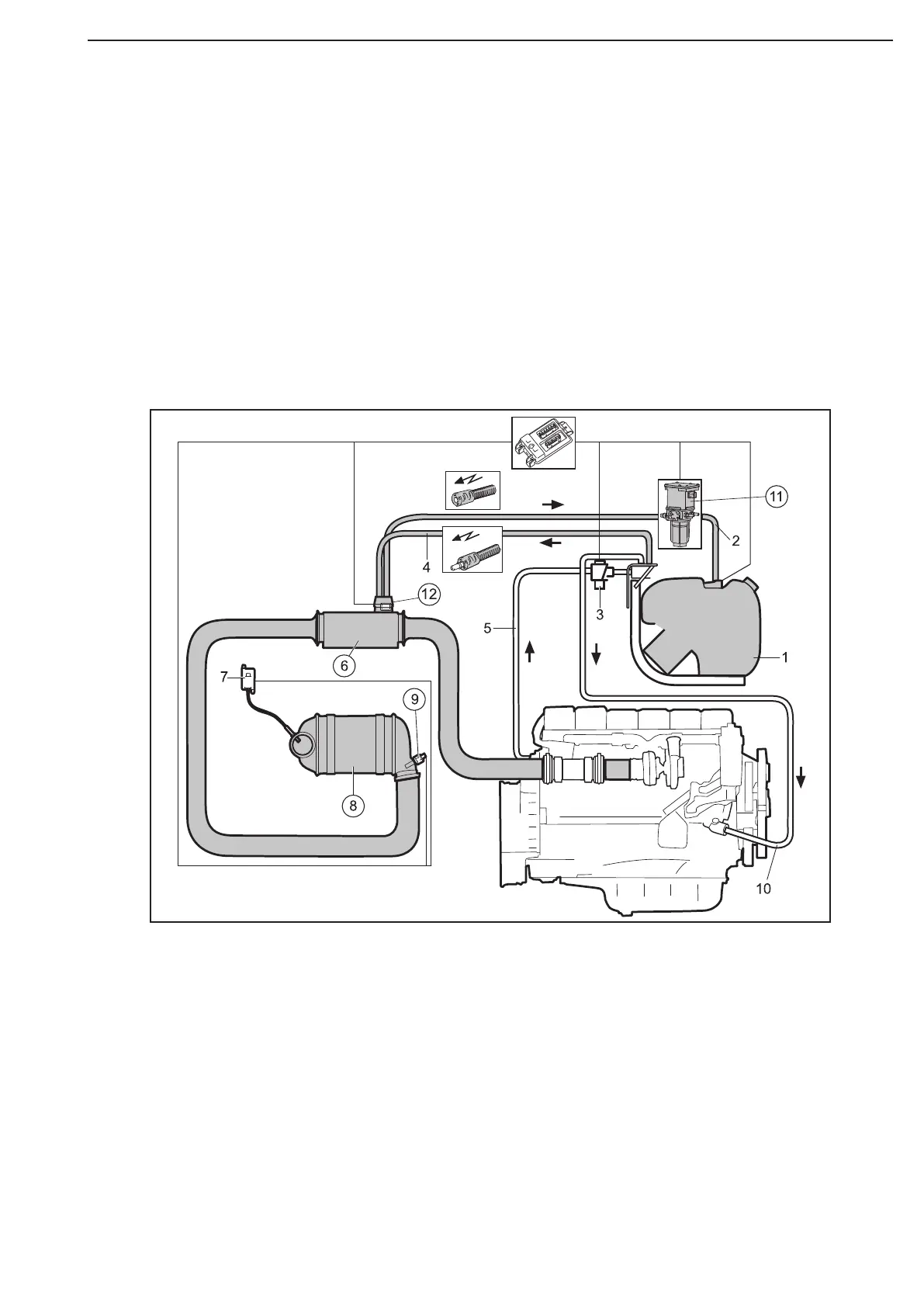

Working principle

The working principle for exhaust gas aftertreatment is divided into three different operations:

Starting

Operation and reductant metering

Shutdown

Starting

The reductant pump starts when the following has taken place: The engine has started, the EEC3 control unit

has carried out a system check, the catalytic converters have started to heat up and have reached the correct

operating temperature (200–250°C) and any heating of the reductant is finished. The reductant pressure is built

up to 9–10 bar to then be injected into the hydrolysis catalytic converter by the reductant doser.

The EEC3 control unit monitors the values and functions of all sensors

The engine is started

The reductant pump (11) starts and builds up the reductant pressure to 9–10 bar.

When the temperature sensor (9) indicates that the temperature of the exhaust gases has reached 200–250°C,

the EEC3 control unit activates the reductant doser (12), which starts injecting reductant to the hydrolysis

catalytic converter (6). The dose is determined by the engine control unit EMS on the basis of the combustion

control in the engine which is currently being operated by the engine control unit.

The process in the SCR catalytic converter (8) starts.

Figure 42

Loading...

Loading...