SHOP MANUAL

Engine

Ch 1 page 38

The reductant flows from the inlet at a pressure of about 9–10 bar and first passes the prefilter (2), fills the ducts

after which the sensor (3) reads the pressure and temperature.

The dosage quantity is determined by the opening time of the solenoid valve (5). It opens once per second

and the amount of time that the solenoid valve is open during that second determines the dosage quantity. The

opening time can vary from 5–95% of 1 second. The reductant is metered to the exhaust gases via the nozzle

(4).

After the engine has been switched off, the reductant pump continues to pump reductant to the reductant doser

to cool it, otherwise the reductant doser can be damaged by the heat in the silencer. No metering takes place

but the reductant flows out to the reductant tank via the restriction valve (1) and the outlet. Cooling stops when

the temperature is not critical in the reductant doser.

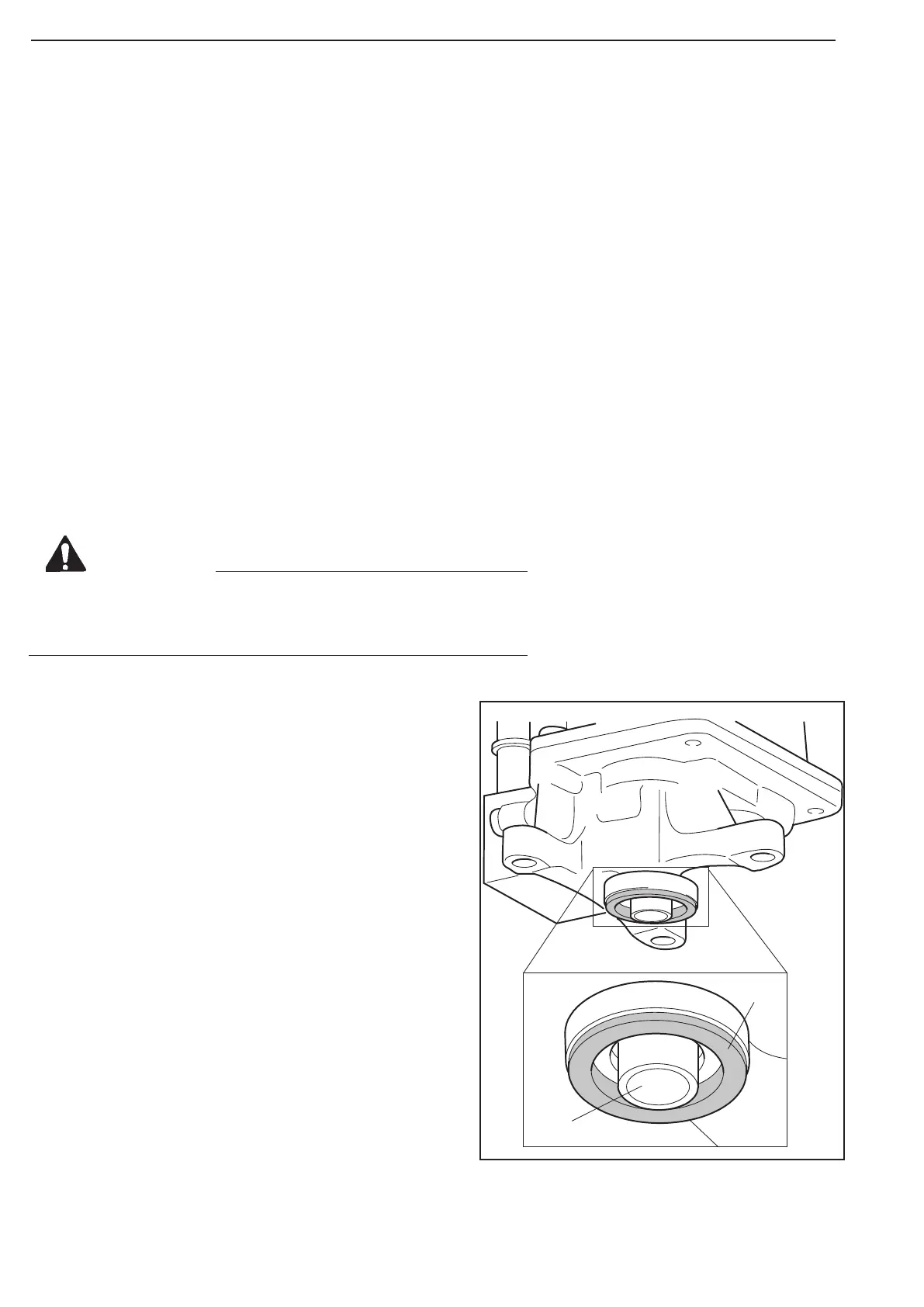

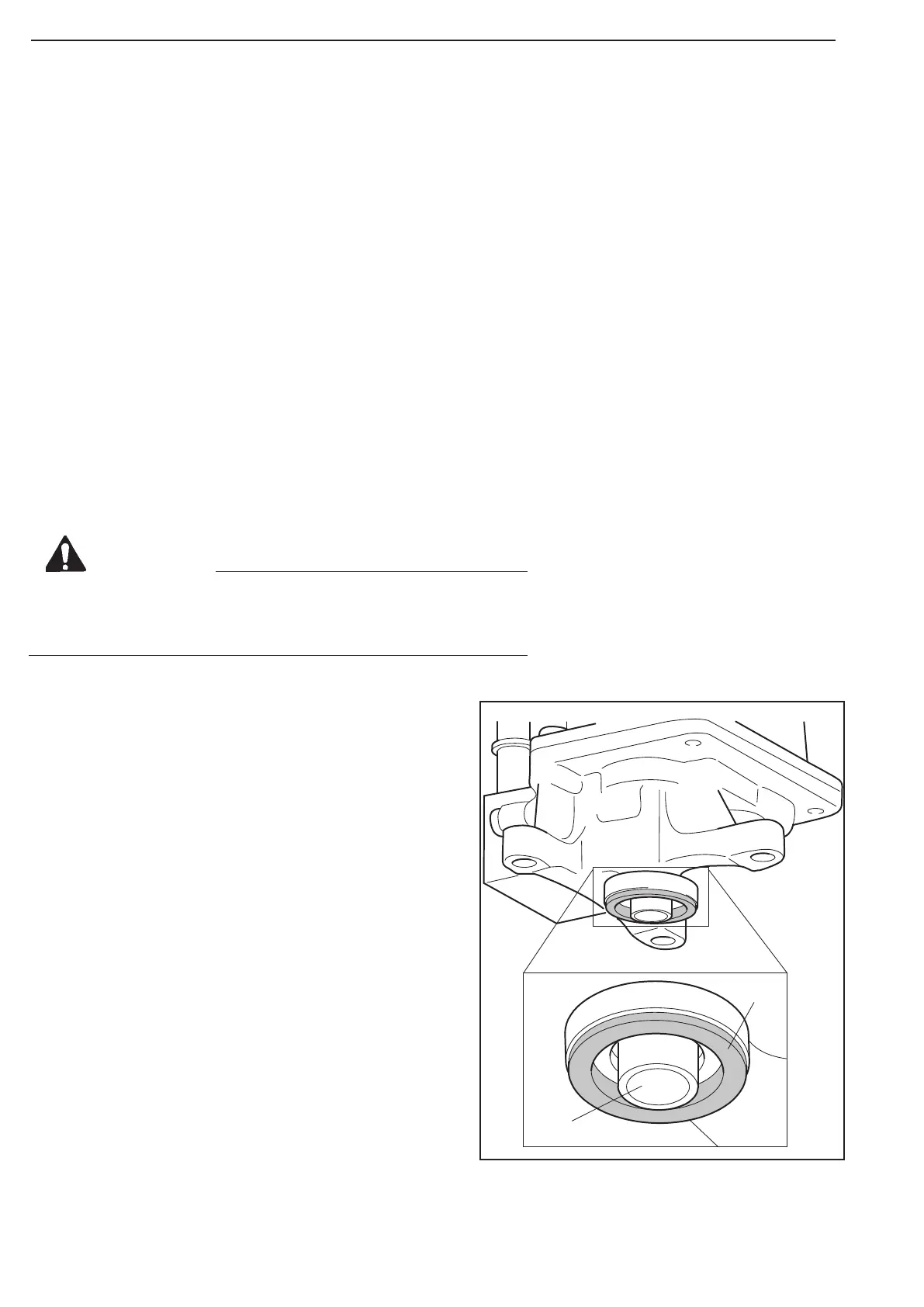

A graphite gasket (1) is fitted on the reductant doser which

seals against the evaporator in the silencer (against the

hydrolysis catalytic converter in industrial and marine

software applications). It should be renewed if the reductant

doser has been removed from the evaporator in the silencer

or the hydrolysis catalytic converter. Also check the nozzle (2).

1

2

Do not switch off the main switch until cooling of the reductant

doser has nished. The reductant doser can be damaged by too

high a temperature.

CAUTION

Figure 57

Loading...

Loading...