SHOP MANUAL

DRIVE LINE

Ch 3 page 34 Ch 3 page 35

DRIVE LINE

Y

6

1

1

1

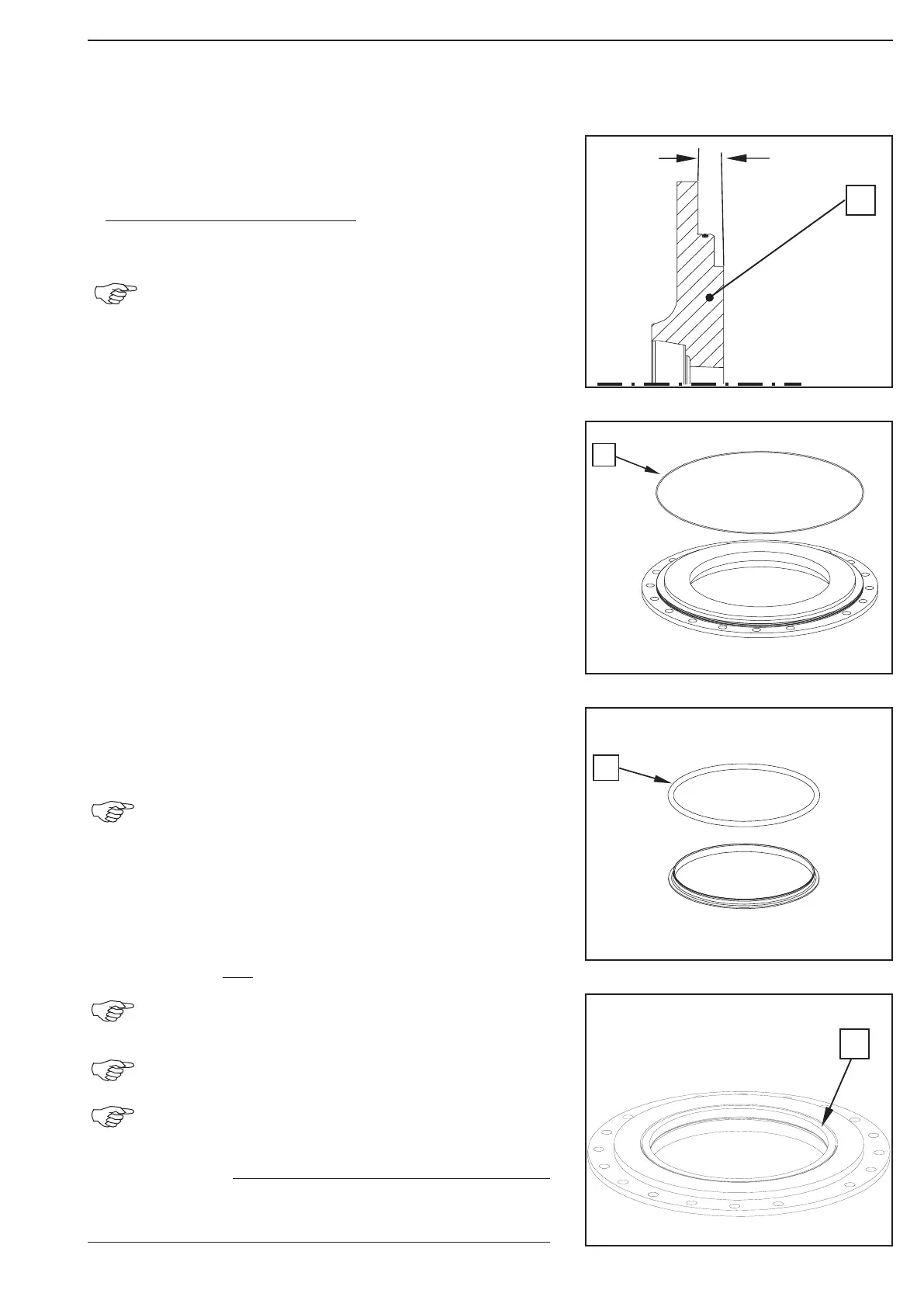

Determination of the clearance for new lined discs (inner discs):

Example:

X ……………………….. = 28.00 mm

Y ……………………….. = 26.60 mm

Clearance = - 1.40 mm

If required, correct the clearance with an adequate outer disc.

Max. clearance for new lined discs: 1.3

+ 0.3

mm

Max. clearance (wear): 4.1 mm

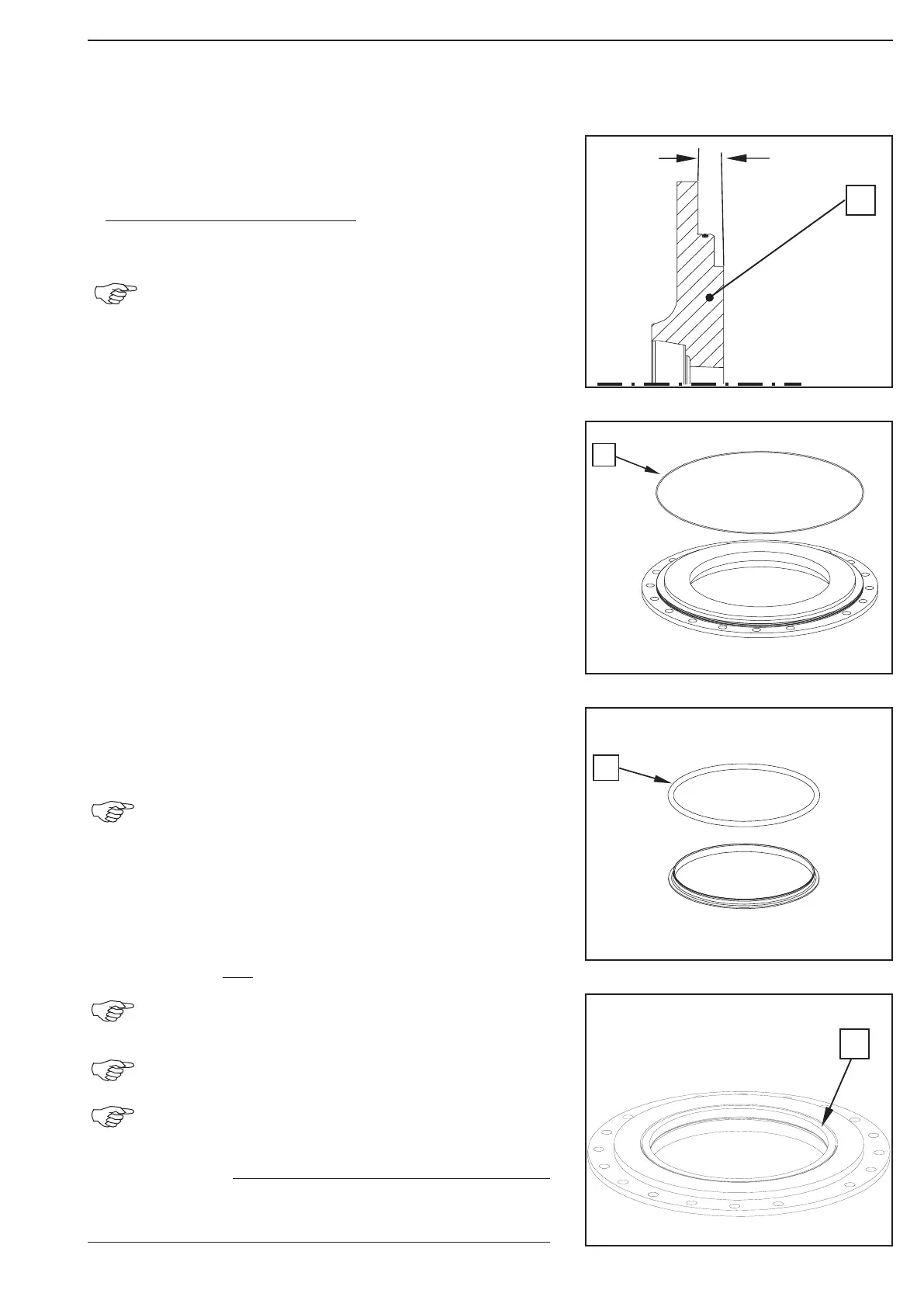

Grease the O-Ring (1) and insert it into the annular groove of the

sealing holder.

Wet O-ring (1) of slide ring seal with spirit and insert into slide

ring guide.

Also wet locating hole of sealing holder (see figure 88) with

spirit.

Any opening of the seal kit necessary for repair work

requires the installation of a new seal kit (slide seal

rings), even if wear limit has not yet been achieved.

Thereupon snap new slide ring seal (1) into sealing ring holder.

Pay attention that sealing surface is in parallel to the

housing surface! The O-rings must be mounted evenly

in the locating hole and must not bulge out of the hole.

The surface of the slide ring seal must not show any

profiled grooves, scratches and other damages!

Also see sketch, Fig. 94 for installation position of the

slide ring seal.

The surface of the slide ring seal must not show any pro-

led grooves, scratches and other damages!

NOTE

Figure 88

Figure 87

Figure 86

Figure 85

Loading...

Loading...