GENERAL INSTRUCTIONS

SHOP MANUAL

Ch 0 page 39

• Be sure to tighten each bolt to the specified torque with a

suitable torque wrench. Apply an even tightening

force to the bolts by screwing them alternately or in a

criss-cross fashion.

• Apply thread locking (see table for sealing/locking

compounds) to important bolts. Prior to coating with

Loctite, wash the bolt with light oil/trichloroethylene or

Loctite superclean.

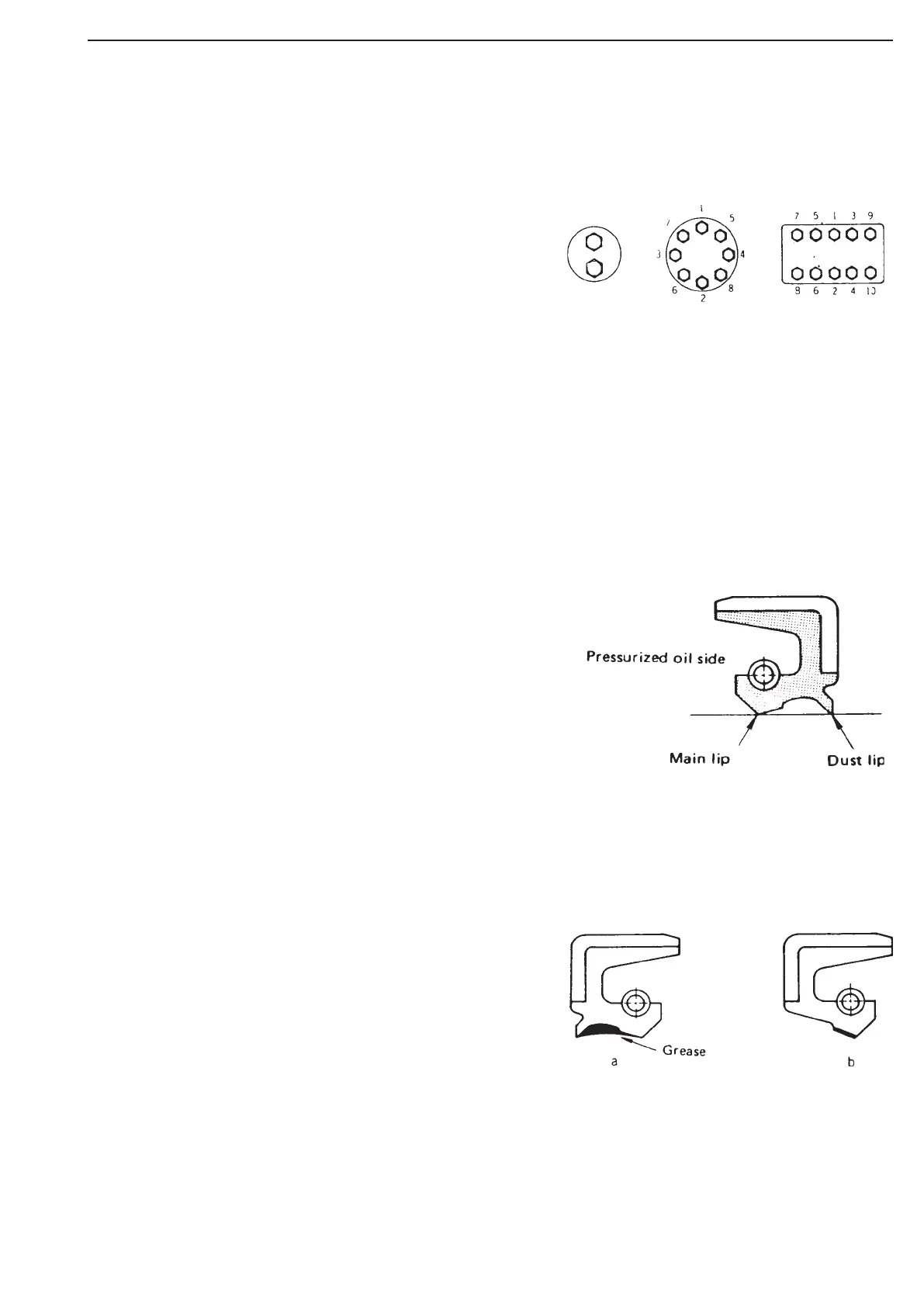

• Tighten bolts in the prescribed sequence figures so that

they can be tightened evenly to the specified torque.

• Be careful not to tighten bolts excessively.

• Be sure to align match marks if provided.

• Keep the working area, tools, worker's hands, etc. clean

during assembly operation.

• Coat the surfaces of parts to be press-fitted with Molykote

grease.

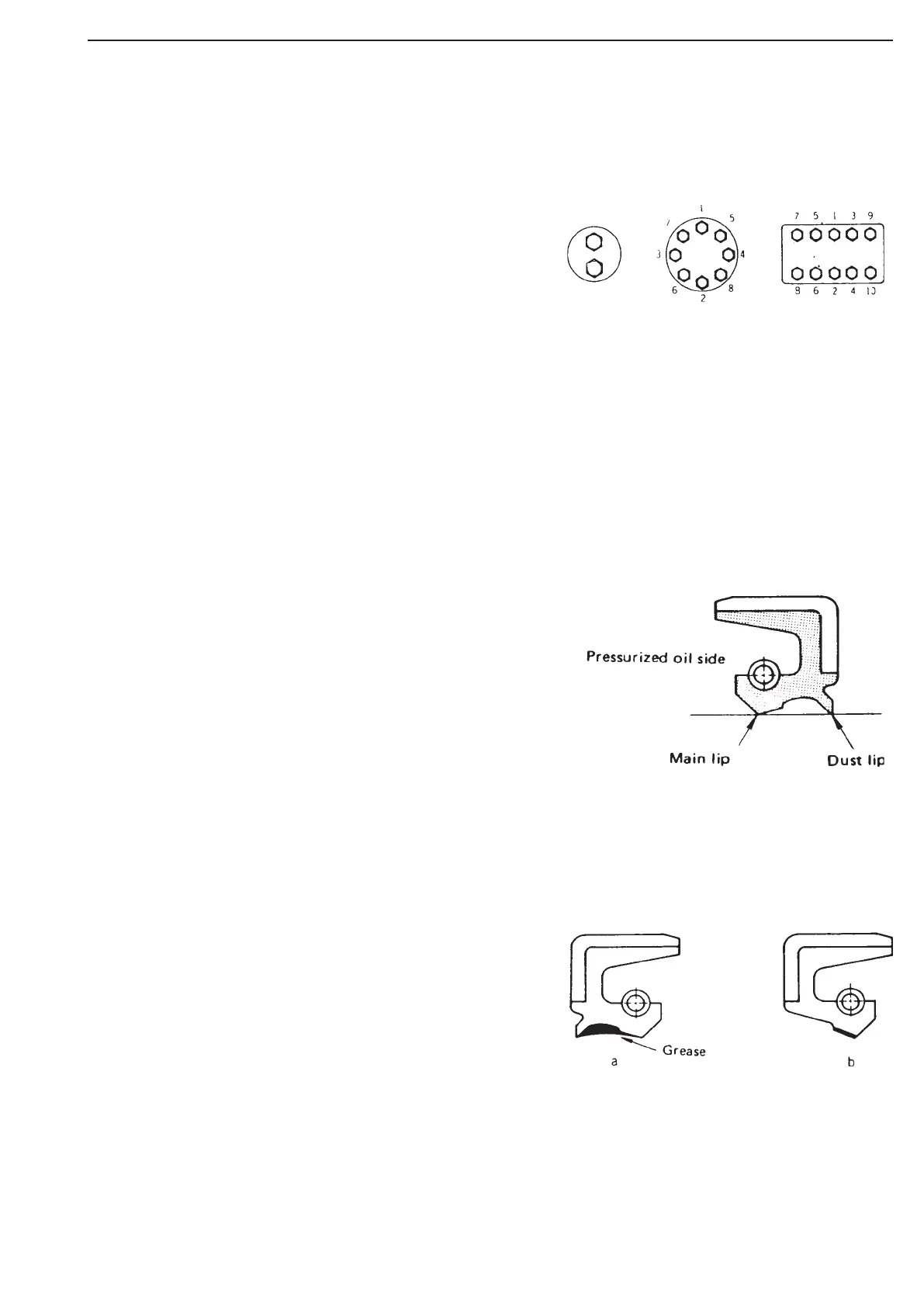

Handling of oil seals

• Be careful to install an oil seal with its lips in a proper

direction as shown below.

• Before installing an oil seal, coat it with grease to pre

vent dry-friction, which may occur during the break-in

operationof the machine, according to the following

procedure:

a) In case of a double-lip type, uniformly coat the surface of

the groove around the lip with grease.

b) In case of a single-lip type, uniformly and evenly coat the

surface surrounding the lip on the opposite side of the

sealing surface of lip.

Loading...

Loading...