GENERAL INSTRUCTIONS

SHOP MANUAL

Ch 0 page 41

Handling of bearings

• Keep the bearings and their surroundings clean. Every dust

and dirt particle, even though they are invisibly small can

affect bearings. Always take sufficient care to protect

bearings against dust and dirt.

• Handle bearings with the utmost care. Because of the high

precision structure and the increased hardness which is

provided by heat-treatment to improve wear resistance,

bearings require special care to handle them. Shock due to

careless handling of bearings will cause dents to form

on the inner and outer races or break the bearings.

• Avoid excessive heating. The hardness of bearings will be

lowered at temperatures higher than 120°C, this may cause

considerably reduced life of the bearings.

• Use the proper jigs for handling the bearings. Under no

circumstances should any other jig be used as a substitute

for the proper one.

• Take necessary rust-preventive means.

• Keep the work where bearings are to be handled clean.

Also, do not unpack a bearing package

until just before the installation of the bearing.

• Be carefull not to drive an outer race onto an inner race by

tapping the outer race, and vice versa. Such unreasonable

handling will cause dents to form on the sliding surfaces

between the races, and the bearing will be damaged early in

its life.

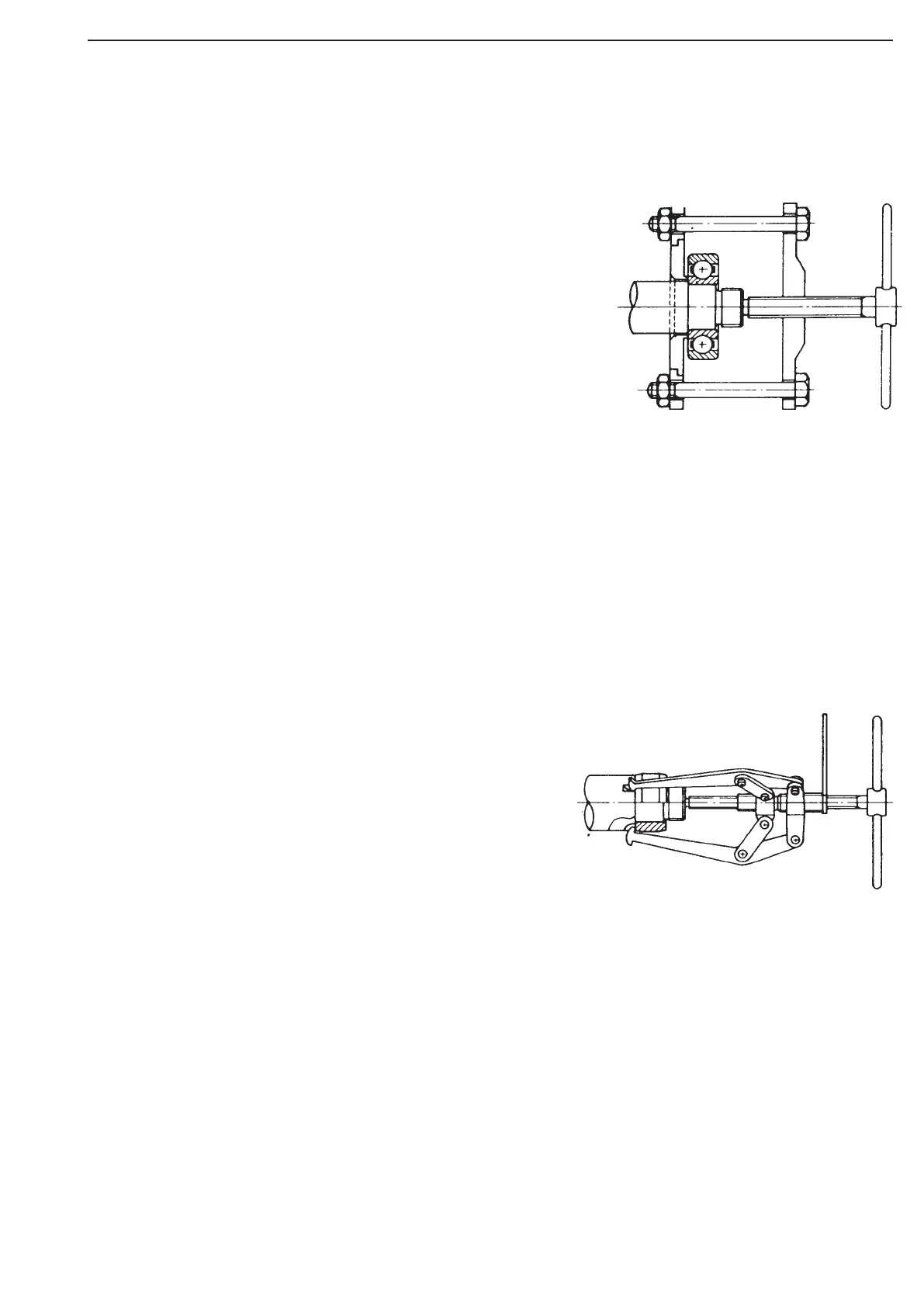

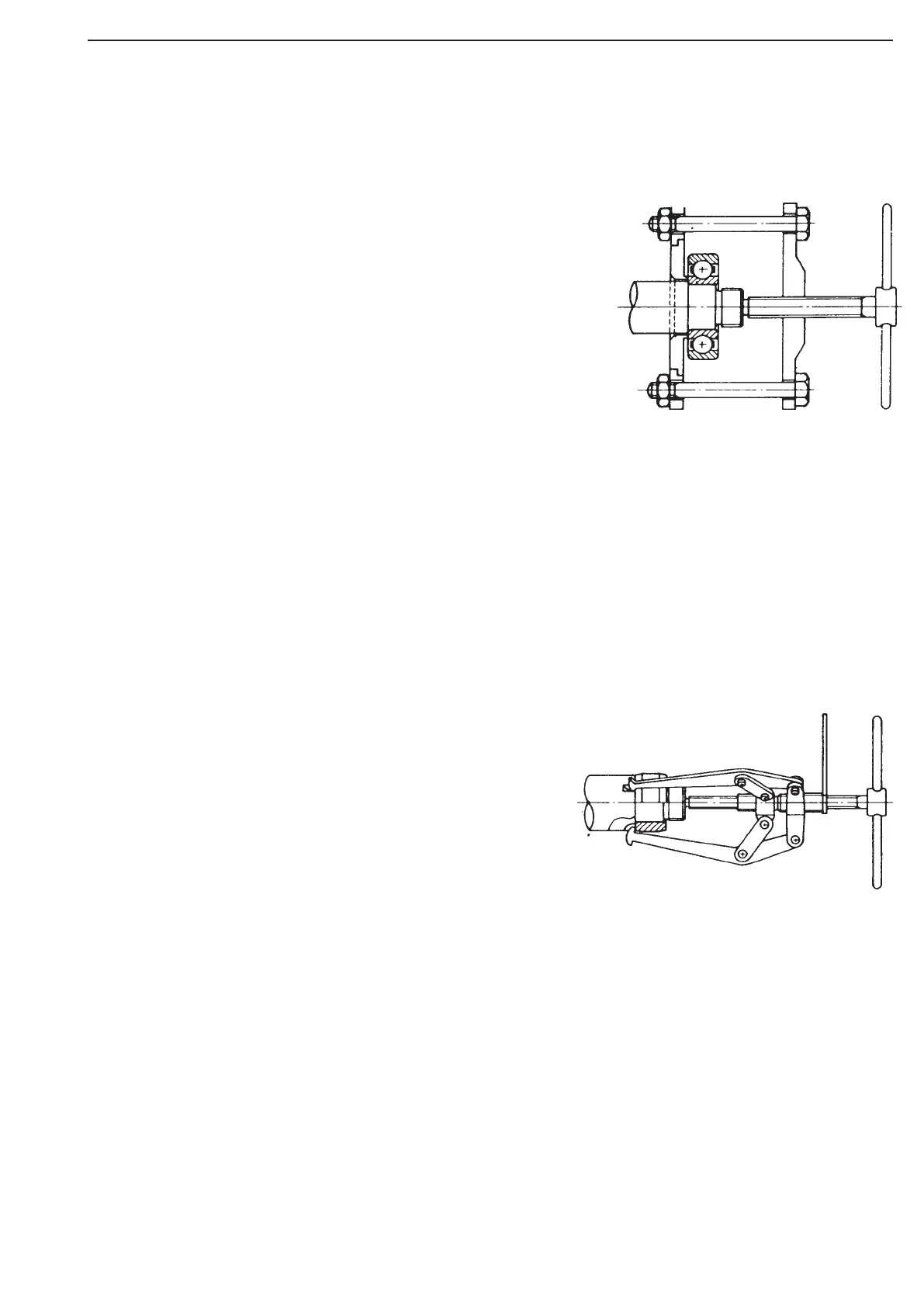

• Be careful not to force a bearing for removal. The use of a

proper removing jig shown below is recommended.

• To wash bearings, neutral and anhydride solvents such as

light oil and kerosene may be used. Two vessels filled with

washing oil should be provided; one for washing dirty

bearings and the other for rinsing. Rapidly shake a soiled

bearing in the washing oil to remove dirt. Rotating bearing

races, instead of shaking the bearing in the washing oil,

should be avoided because bearing races may be damaged

by foreign particles such between the races. It is also

necessary to keep washing oil clean by filtering it from time

to time.

Loading...

Loading...