SHOP MANUAL

DRIVE LINE

Ch 3 page 168 Ch 3 page 169

DRIVE LINE

Prepare stand for the hub work over

Assemble the

wheel bolt.

Use hydraulic press or

sledgehammer.

Preassemble the distance ring

Insert 2 pcs. screws plug and

O-ring

Lubricate the O-ring and use

locking compound (tread lock)

Tree Bond 5111to lock the

screw plug.

Clean the axle

and apply oil

Assemble the distance ring.

Check the ring is in contact

with the axle flange

l ring

nd the ring

ith care, replace worn rings with new

the rings (Only as set)

surfaces before assembly

Assemble the outer bearing.

Clean the axle and apply oil

before assemble the bearing.

Heat the bearing with

electrical heater or hot oil

Temp 75 - 90°C

(167 - 194°F)

Hold press to the bearing

until cool down

Turn the hub housing

180 ° while assembly

the bearing cup and

the seal

Clean the bearing surface and

assemble the bearing cup

Clean the surface and

assemble the seal ring

Place the hub in assembly rack after assemble

of the bearing cup and the seal ring.

Be careful with the seal ring

Insert the plug

Clean the bearing surface and

assemble the bearing cup

Assemble the guide ring

Pos 23-24

Assemble the piston ring

Pos 21 - 22

Assemble the guide ring

Use glue: Loctite no.406

at both ends.

Lubricate seal area

before inserting the

piston.

Preassemble the Return mechanism- piston

X

1

2

3

4

5

Figure 26

Legend to the sketch:

1 = Pin

2 = Gripping rings

3 = Cup springs

4 = Support shim

5 = Circlip

X = Installation dimension Gripping rings 8.2 +0.3mm

For more details about assembling

of the return mechanism, see

description in the Sho

p Manual,

bly.

Place the return mechanism lock ring

Assemble 6 pcs. of the slot pin

into the return mechanism

Slot pin 6x20 DIN 1481

Calculation example:

Measure A.................................. 47,10

Measure B.................................- 6,40

Gives:..........................................= 40,70

Discs unit.................................. - 38,60

Clearance.................................. = 2,10

Allowed clearanse 1,7 - 2,1 mm

B

A

Place the "line up tool"

Moxy part No. 514663

Apply oil to the parts and place th

e

brake disc, one by one.

Start assembly with outer disc.

1 The outer disc (5 pcs, different t

hickness available)

2 The inner disc (4 pcs. thickness

4,7 mm)

4.0

4.0

4.0

4.0

3.8

Example

Clean the surface and

place the O-ring

Place the flange

20 pcs . screw M16x50 ISO4017-10.9 EL

Apply locking liquid: Tree bond 1374

Washer 17x30x3 NS-ISO 7089 300HV

Tightening torque: 280 Nm.

0 bar

50 bar

Pressure test:

Increase test pressure up to p = 50 bar an

d close the

connection to the HP-pump by means the

of shut-off valve.

During a 5 min. testing time a pressure dr

op of max. 2 %

Shut of valve

he press is stay on !

Lubricate the parts and

assemble the carrier.

N

ow, remove the

ressure tester,

nnect lifting device

sealring

nd careful

l ring on

of the hub

mbly the

axle.

e

ice.

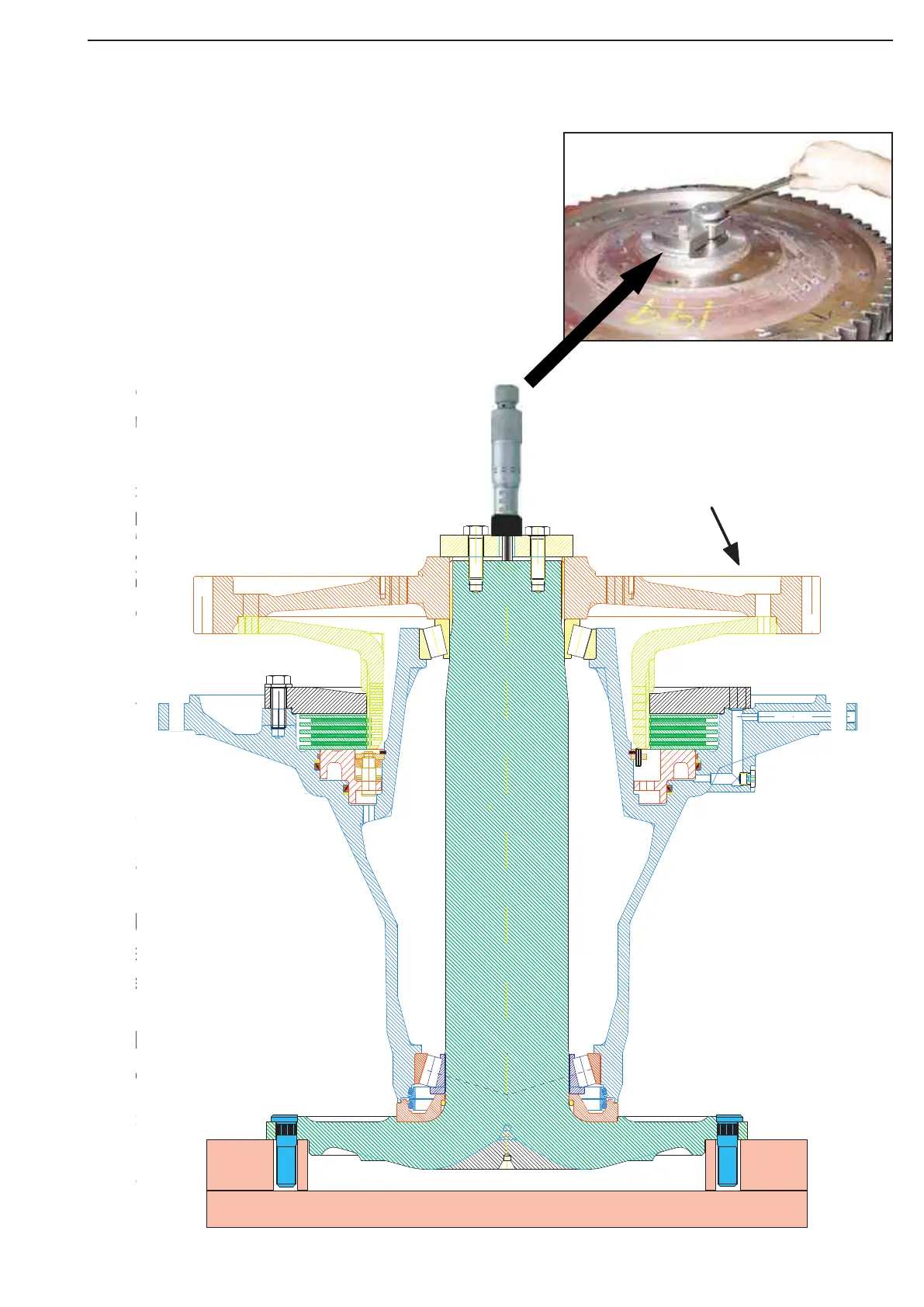

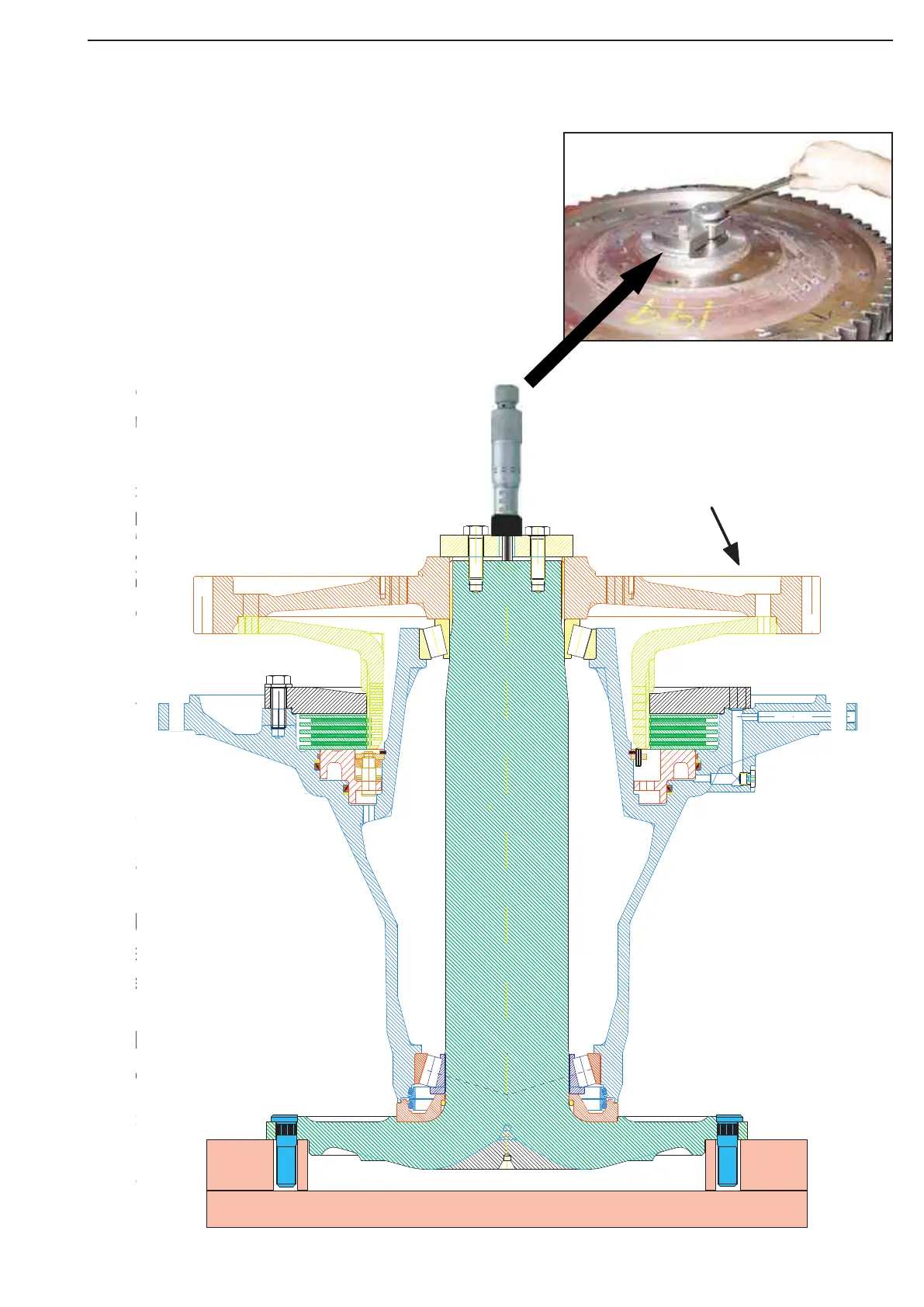

Prepare to assemble the roller bearing:

Clean the hub axle and bearing cup.

Apply lubricant.

Assemble the inner bearing.

Clean the axle and apply oil

before assemble the bearing.

Heat the bearing with

electrical heater or hot oil

Temp 75 - 90°C

(167 - 194°F)

1)

Assemble the gear wheel

to contact with the bearing

inner ring.

NOTE: Do not press !

2)

With no press rotate the axle

20 times.

m

Resistance :

8 - 17 Nm.

(3)

Check the rolling resistance.

Resistance : 8 - 17 Nm.

NOTE:

At this stage, no preload on the bearing

(Free spinning)

Place the end plate and with 2 screws

assembled, torque the screw until the

rolling resistance now is +20 Nm

from previous check 28 - 37 Nm. (total)

Measure the clearanse between end

plate and the axle end.

(Example 2,20 mm)

NOTE!

At this stage the screw for

connection the gear wheel

and the carrier not is

assembled

Figure 503

Figure 504

Loading...

Loading...