SHOP MANUAL

DRIVE LINE

Ch 3 page 54 Ch 3 page 55

DRIVE LINE

The mounting and dismounting of rolling bearings involve

the handling of sometimes heavy weights, the use of tools

and other devices, and in some cases the use of high pres-

sure oil. In order to avoid accidents, injuries or damage to

property please follow carefully the prescribed methods.

Arrange the one V-ring with sealing washer on the shaft. The V-

ring should be furthest away from the bearing and seal against the

washer, i.e. the lip should point inwards towards the washer.

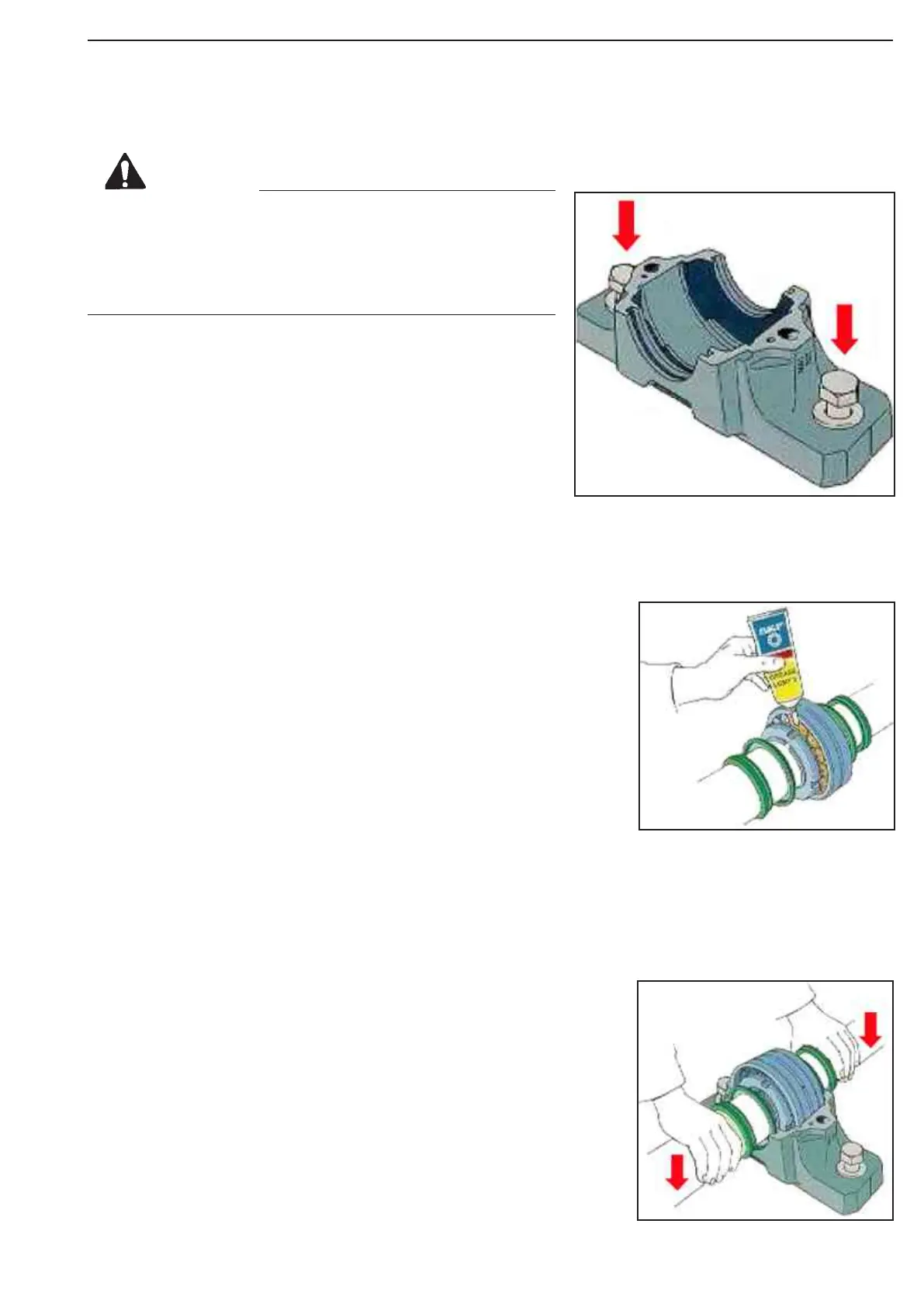

Mount the bearing on the shaft - either directly on a stepped shaft

or using an adapter sleeve. Completely fill the bearing with grease.

The remainder of the recommended grease quantity should be put

in the housing base at the sides.

Arrange the second sealing washer and V-ring on the shaft at the

other side of the bearing. If the housing is to be used at the end of

a shaft, mount an end cover instead.

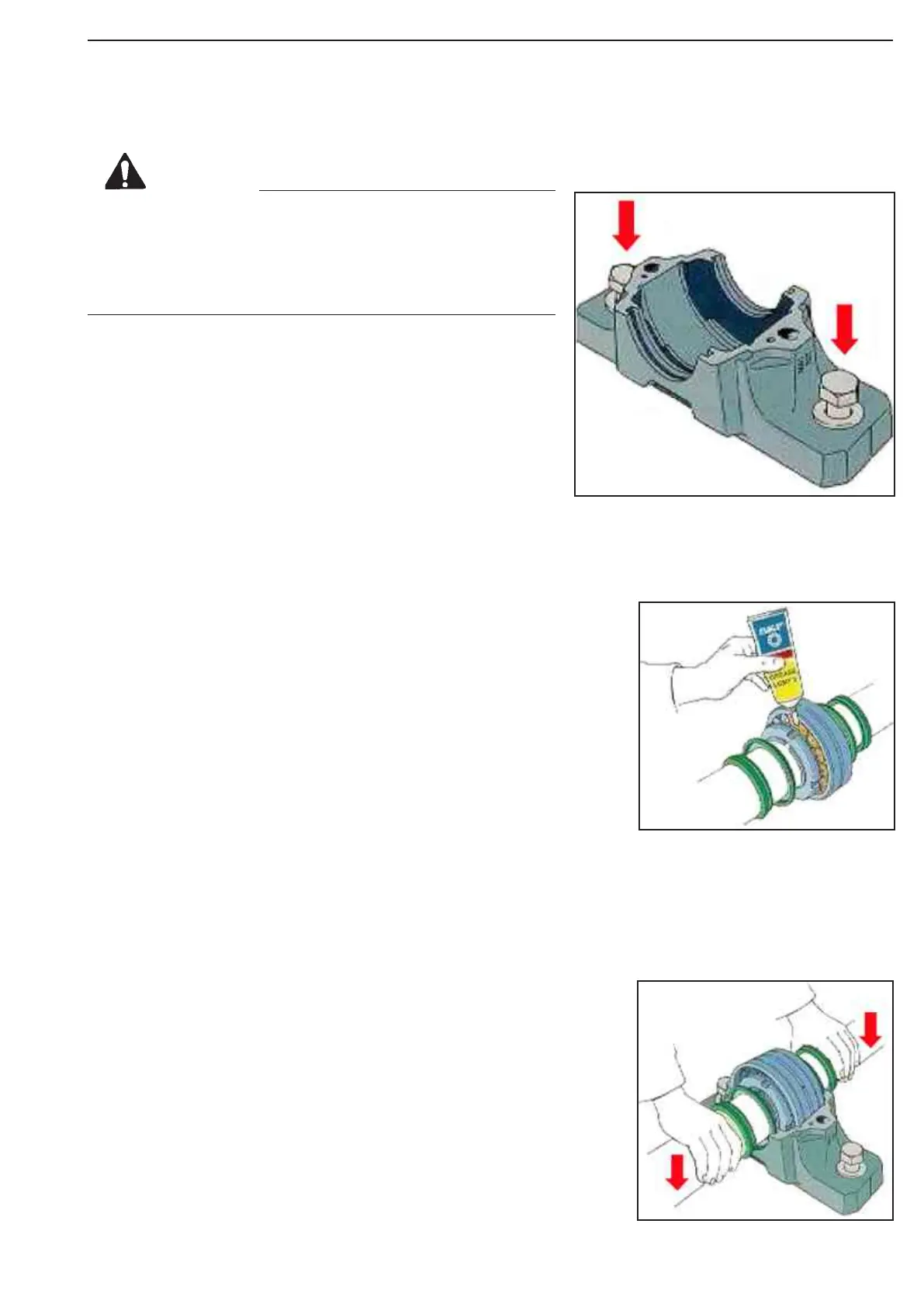

Lay the shaft with bearing and sealing washers in the housing

base.

Put the locating rings (when needed) at each side of the bearing.

NB: locating rings are only used for locating bearing arrange-

ments.

Ensure that the environment is clean.

Determine the position of the housing. The grease nipple arranged

at one side of the housing cap (for improved lubrication) should

always be at the opposite to the sleeve nut. it is necessary to

consider the complete housing as the base and cap will only fit

together as supplied.

Position the housing on the support surface. Fit the attachment

bolts but do not tighten them.

CAUTION

Figure 153

Figure 152

Figure 151

Loading...

Loading...