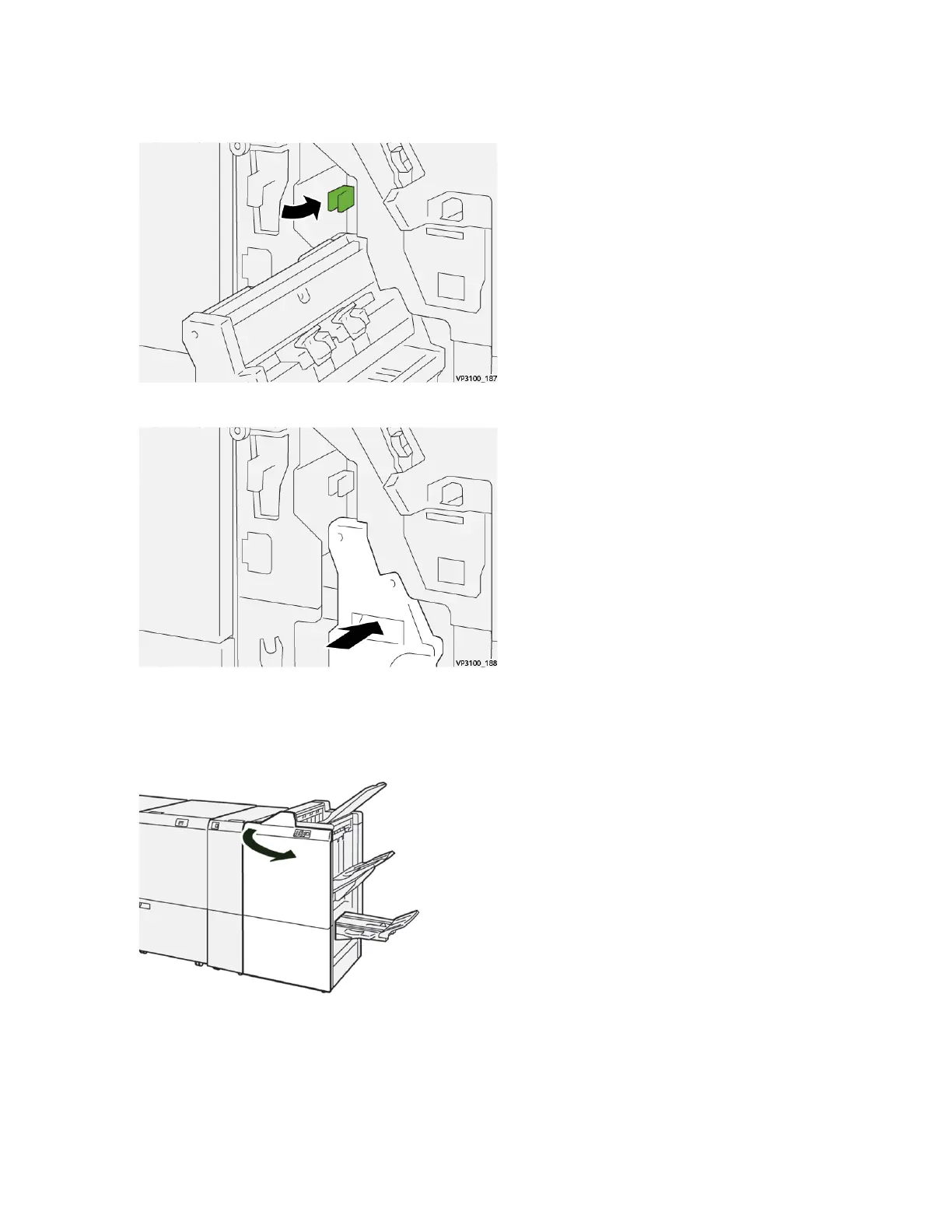

4. Return lever 3a to its original position.

5. Gently push in the Saddle Stitch Unit 3 until it stops.

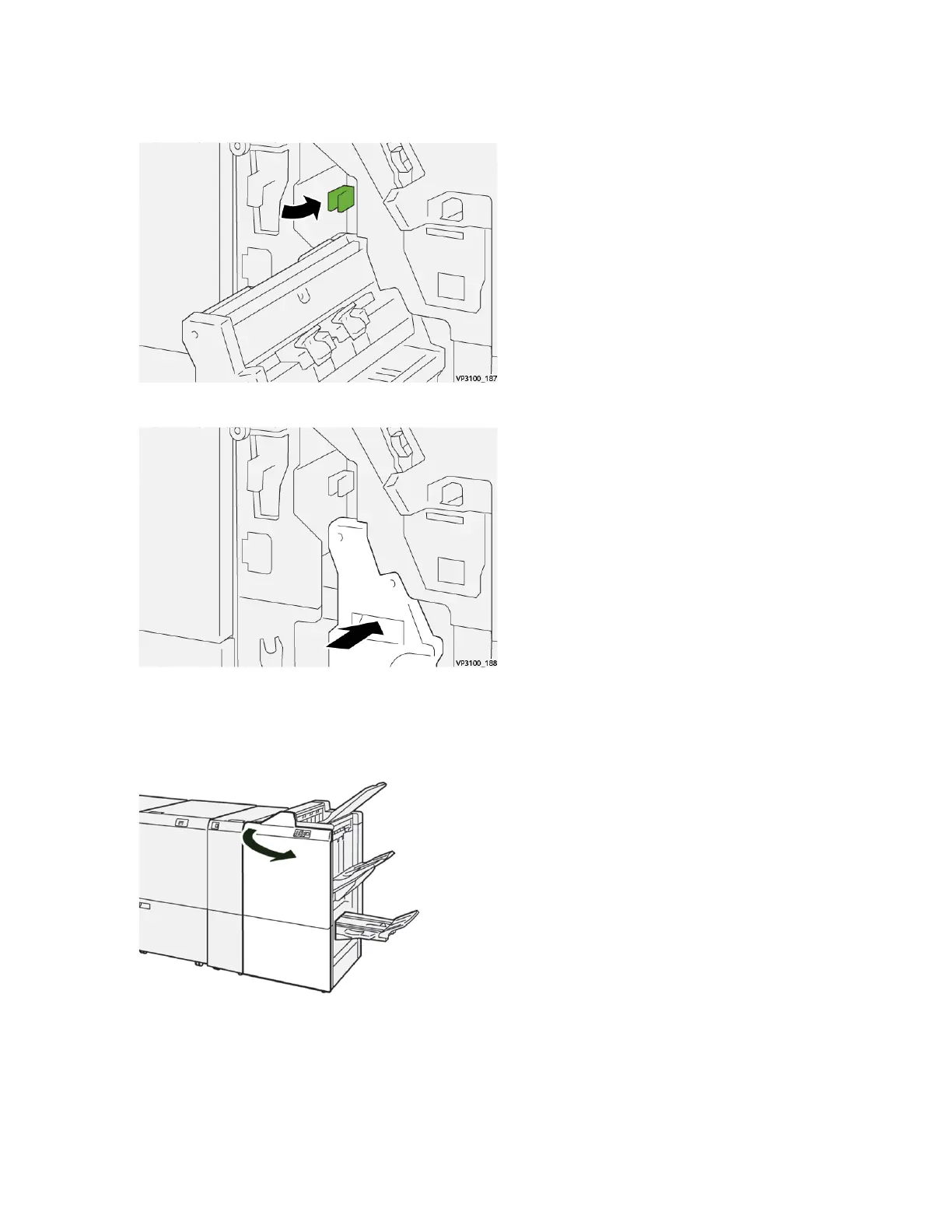

6. Close the finisher front cover.

Clearing Paper Jams from Finisher Booklet Area E8

1. Open the finisher front cover.

402 Xerox

®

Versant

®

280 Press User Documentation

Troubleshooting

Loading...

Loading...