Site Preparation and Installation

26

Magellan™ 9800i Scanner

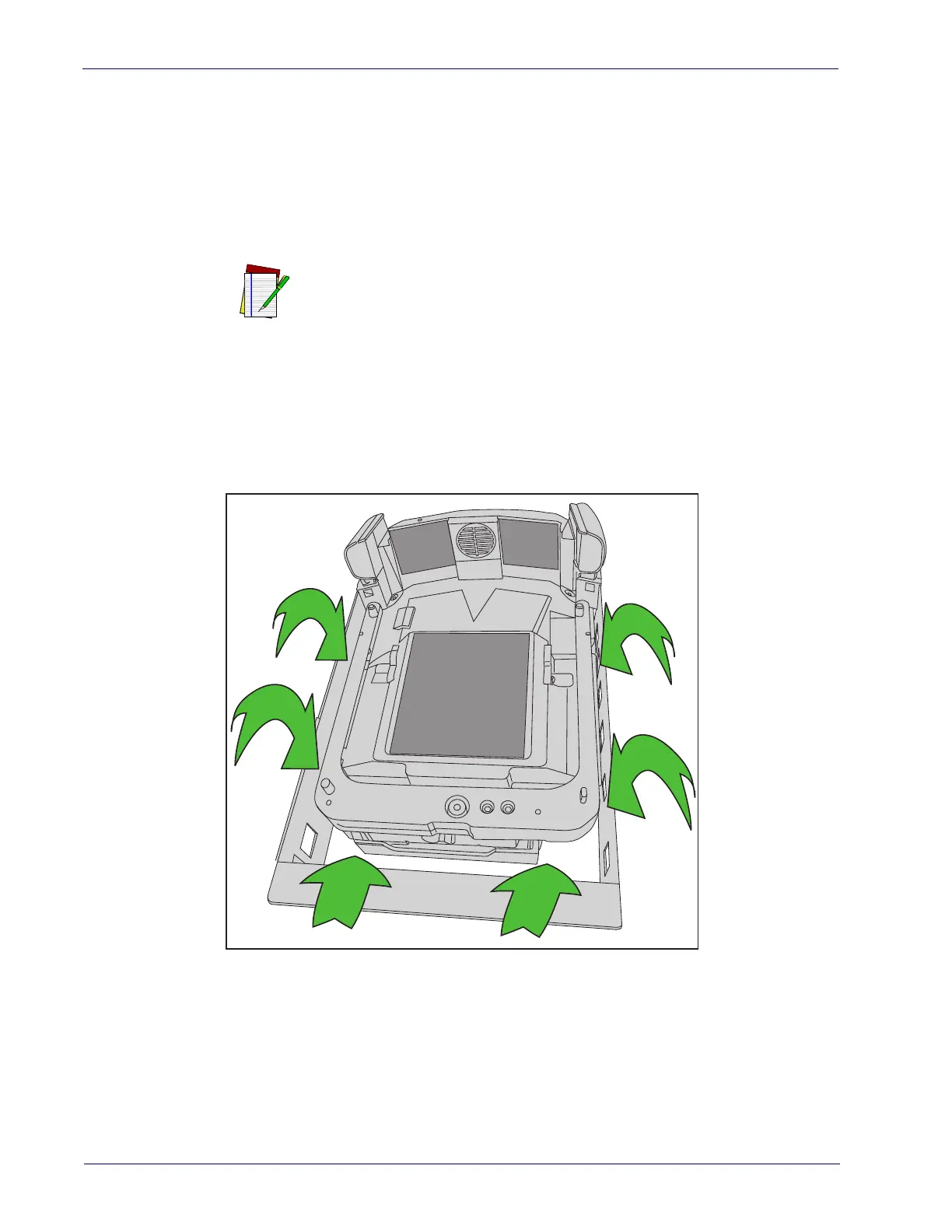

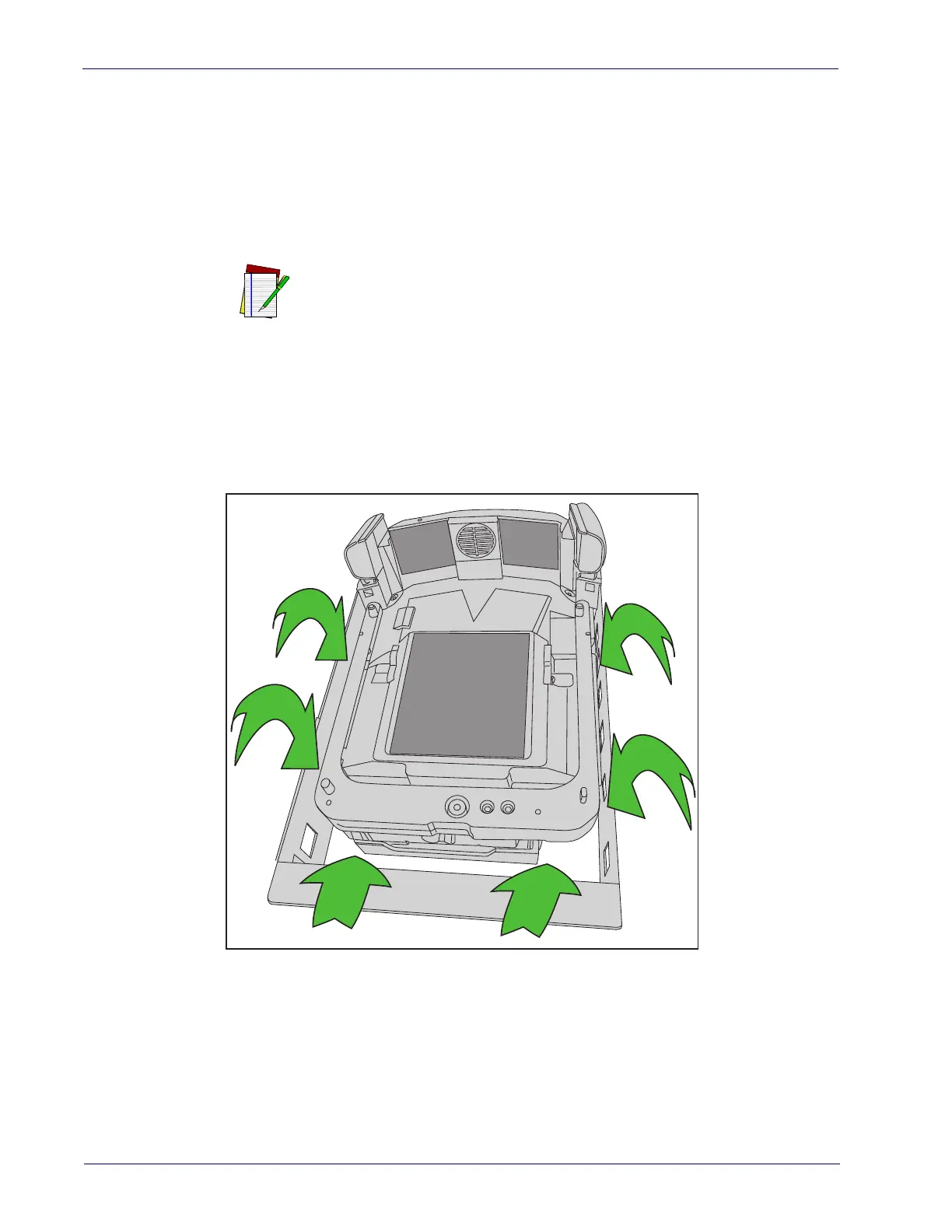

Ventilation and Spacing

The scanning-scale’s perimeter housing has been designed to provide adequate space for

convective cooling and unrestricted movement of the weighing apparatus.

Figure 13 shows the

debris chutes and ventilation slots. The checkstand design must...

• keep the ambient air temperature inside the checkstand adjacent to the scanner below

1

04°F (40°C).

• allow a source of air that provides adequate coolin

g by convective air flow.

NOTE

DO NOT place the scanner in a close-fitting, fully enclosed checkstand. Provide a

MINIMUM of 16 square inches (103.2 square centimeters) of air intake from below

the installation for sufficient convective cooling.

If motors, conveyor belts, or other heat producing equipment are located near the scanner,

forced air ventilation may be required. In most installations, a 30 cfm (.84 cmm) axial fan

should provide sufficient air movement. If a ventilation fan is installed, it is recommended to

use one with a removable filter that may be washed or replaced.

Figure 13. Debris Chutes & Ventilation Slots

(Models vary)

Service Access

The scanner and scanning-scale have been engineered to allow performance of all routine service

and maintenance (such as “zeroing” and calibration) without removing the scanner from the

checkstand. Additionally all cable connections made at the scanner can be connected and

removed while the unit is sitting on the countertop. The installer should provide service access

to all remaining cable connectors as well as the AC/DC Power Supply (if installed).

Loading...

Loading...