Chapter 4 Panel Display and Operation ASDA-A2

Revision February, 2017 4-9

4.4 General Function

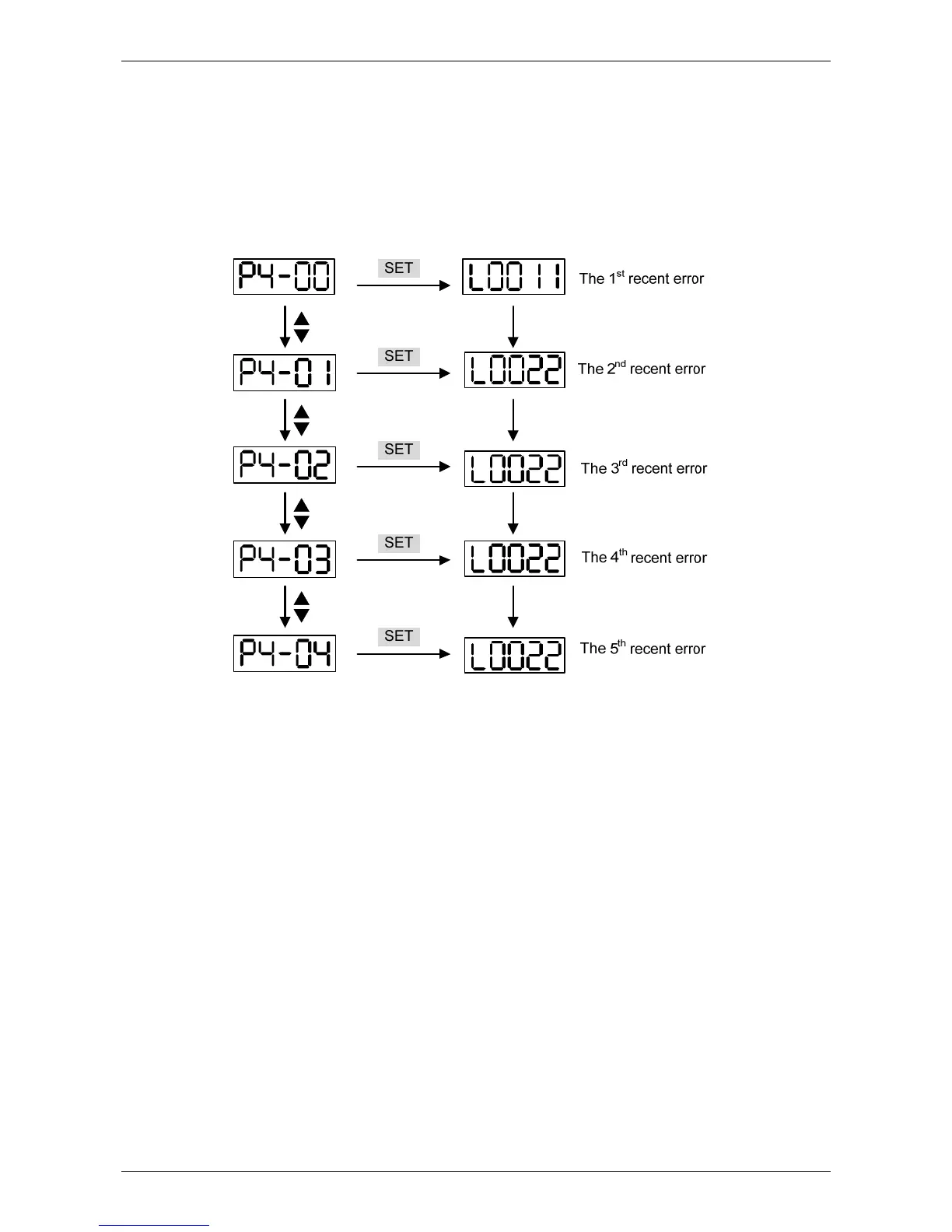

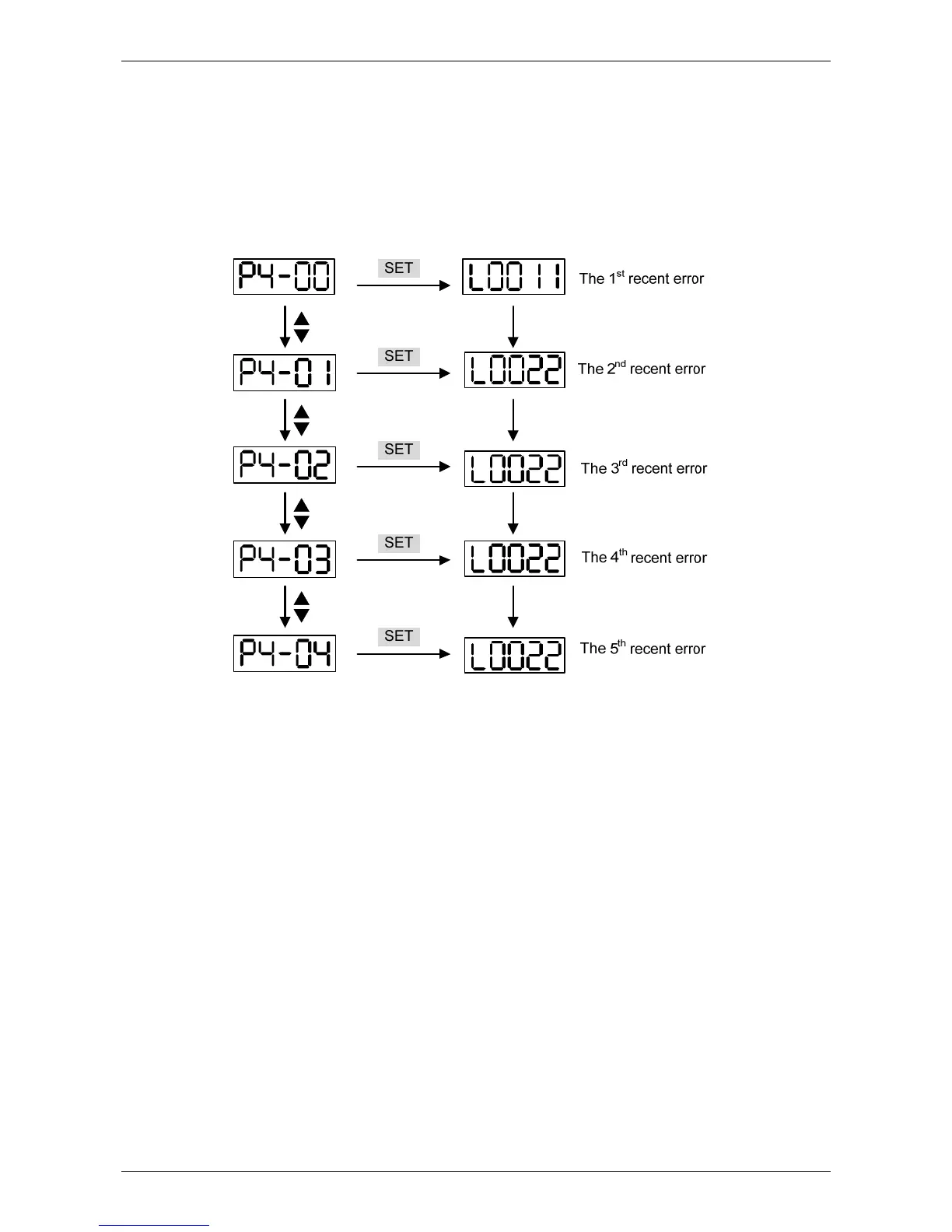

4.4.1 Operation of Fault Record Display

When it is in Parameter Mode, select P4-00~P4-04 and press the SET Key, the corresponding

fault record will be shown

.

Loading...

Loading...