ASDA-A2 Chapter 8 Parameters

Revision February, 2017 8-215

The following macros are available from version V1.042 sub09 (included):

Command code

0008h

E-Cam curve scaling (P5-19) is effective immediately

Macro parameters N/A

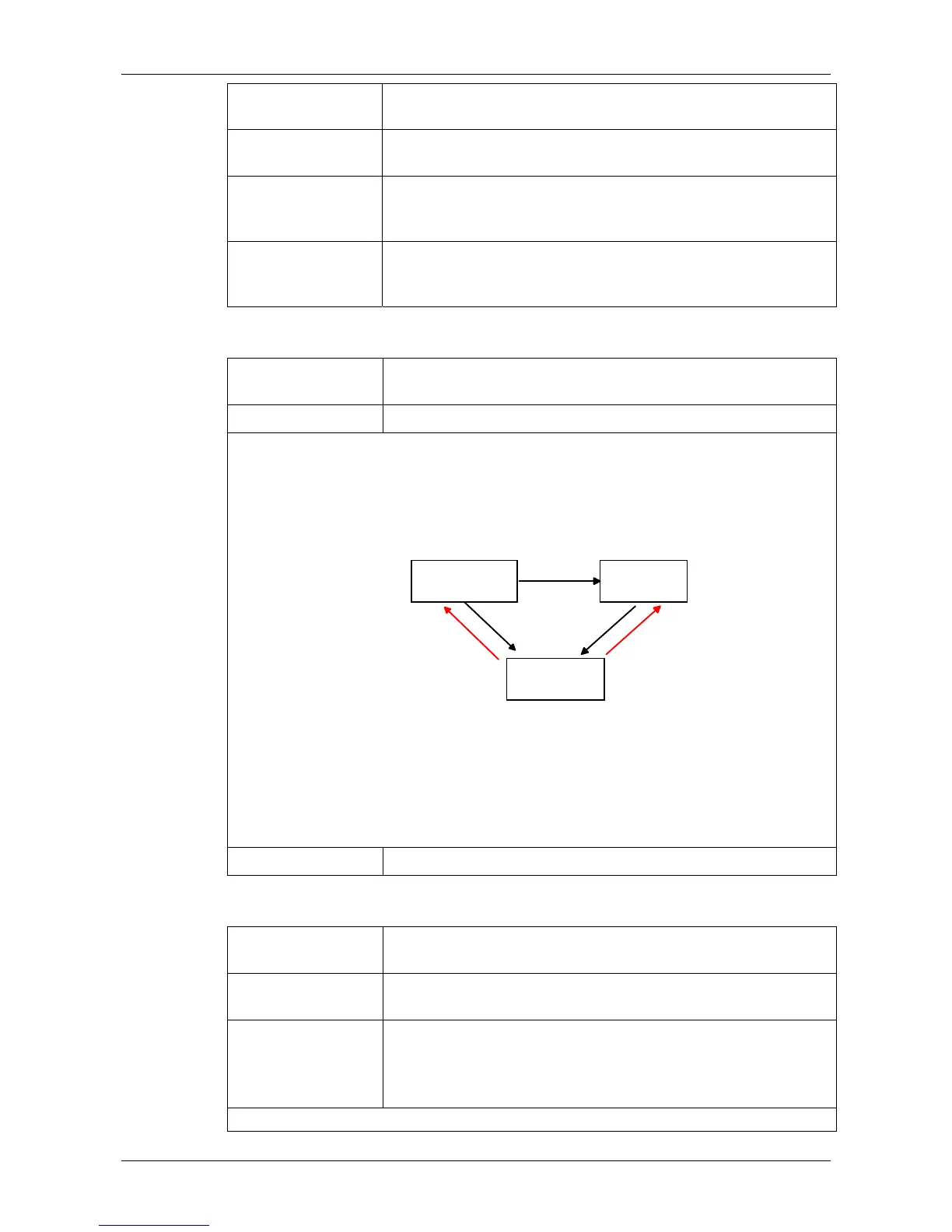

This macro can be triggered when E-cam is engaged. P5-19 is effective

immediately.

Usually, E-Cam scaling is only changed by P5-19 when it entering the engaged

condition (see transition 3). It cannot be changed in engaged condition. E-Cam

scaling only can be changed after one E-Cam cycle so as to make sure the E-Cam

can return to the original position without accumulative error.

Engaged: 1

Stop: 0

Lead: 2

1

2

5

4

3

P5-19 is loading into

E-Cam scaling.

In application, two ways can change the setting of E-Cam curve scaling.

1. P5-88.X2 = 1: When E-Cam is engaged, setup this bit at the same time.

Function of P5-19 will be enabled immediately.

2. Use macro#8: Every time when this macro command is triggered, function of

P5-19 will be enabled. However, if the value of P5-19 is changed and this

macro is not triggered, function of P5-19 will not be enabled. This macro

command has to be triggered again.

Failure code N/A

The following macros are available from version V1.035 sub00 (included):

Command code

000Ch

Change position X, where E-Cam is engaged: E-Cam

disengages after rotating one cycle at forward direction.

General

parameters

N/A

Macro parameters P5-93 = New engaged position X. Unit: pulse number of

master axis.

Monitoring variable 062(3Eh): It displays the current engaged

position (X) of master axis.

This macro command can change the engaged position even when E-Cam is

Failure code F077h The address specified by P5-81is too long and the space of

data array is not enough.

Failure code F078h Data calculation error. Please decrease the setting value of

(P1-44, P1-45) and keep the proportion will do.

Failure code F079h Acceleration degree is too small, and then please decreases

the value of waiting area (W), synchronous area (Y) or curve

level (S).

Failure code

F07Ah

Waiting area is too small, then please increase the value of

acceleration area (W) or decrease the value of synchronous

area (Y)

Loading...

Loading...