ASDA-A2 Chapter 10 Troubleshooting

10-20 Revision February, 2017

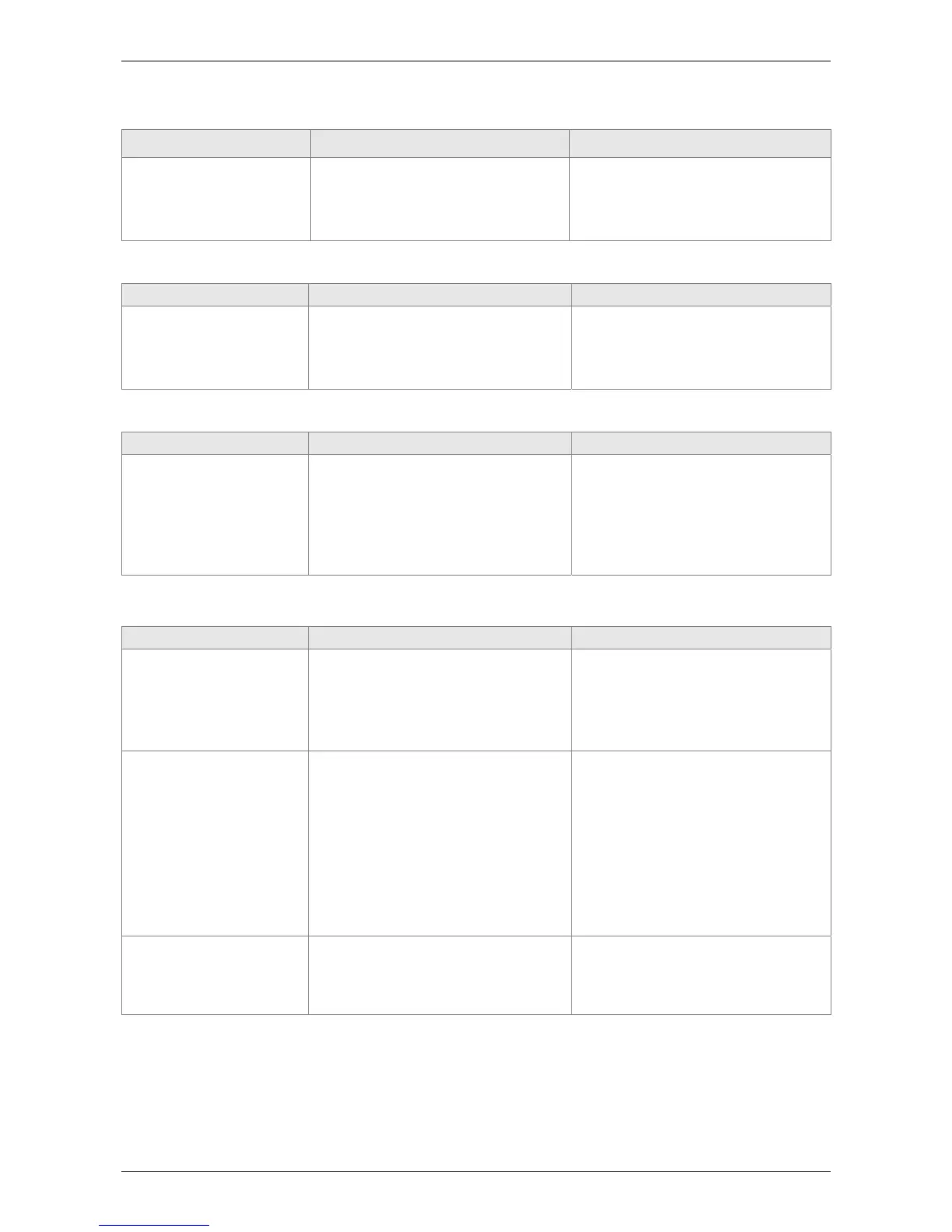

AL069:Wrong motor type

Causes Checking Method Corrective Actions

Incremental motor is not

allowed to activate the

absolute function

1. Check if the motor is

incremental or absolute

encoder.

2. Check parameter P2-69.

If the user desires to use absolute

function, please choose absolute

motor. If not, please set parameter

P2-69 to 0.

AL06A: The absolute coordinate has not been initialized

AL070:Encoder does not complete the command which is issued by servo drive

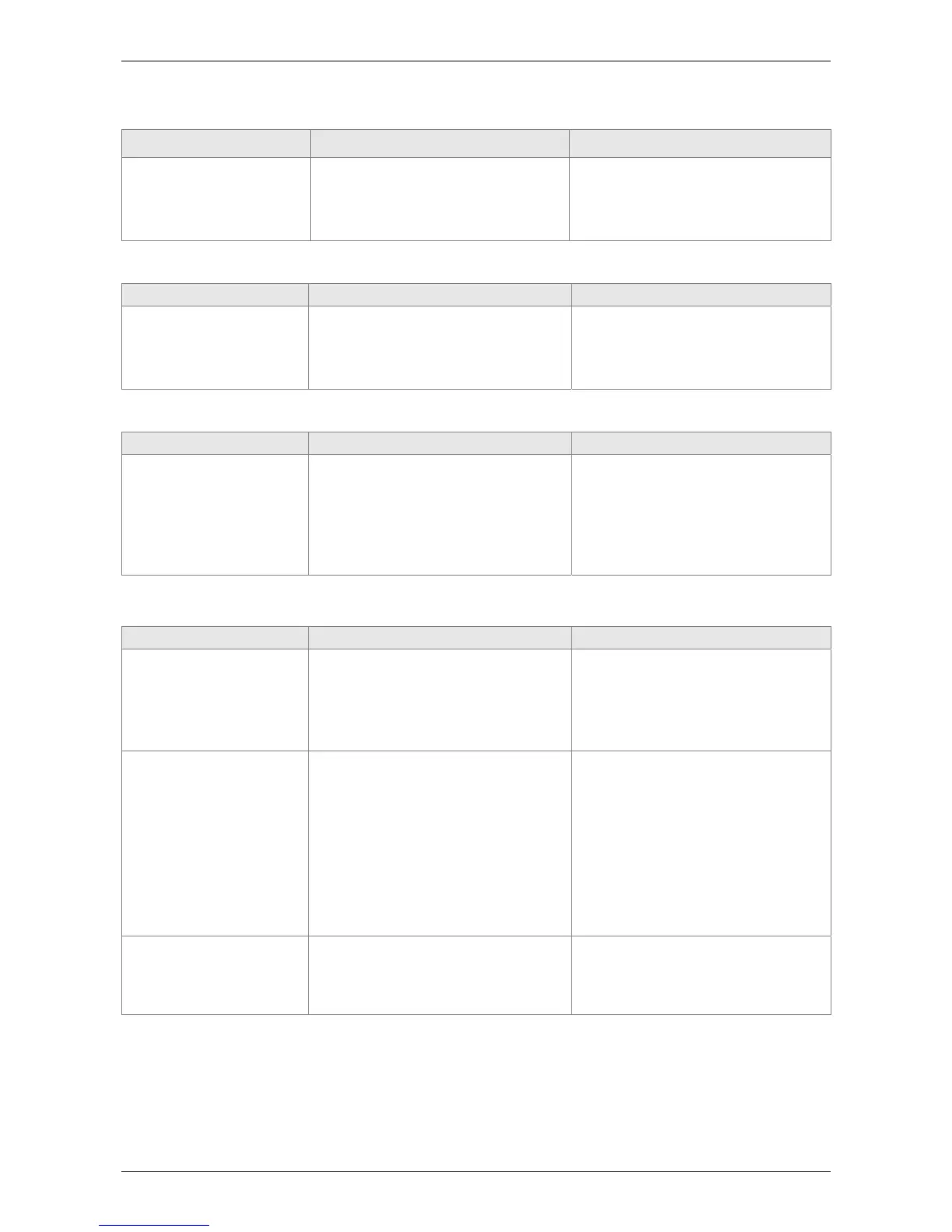

AL083:Servo Drive Outputs Excessive Current

Causes Checking Method Corrective Actions

UVW cable is short-

circuited

Check the configuration of motor

power cable and connector cable.

See if the metal wire is exposed or

AWG is worn and causes short

circuit of UVW cable.

Replace by new UVW cable and

avoid the metal conductor being

exposed so as to eliminate short-

circuit.

Wrong motor wiring

1. If applying non-standard power

cable recommended by Delta,

please check if the wiring

sequence of UVW cable is

correct.

2. Check if there is any problem of

lack phase when connecting

UVW from servo to motor

(unconnected or wrong

connection)

Please refer to the description of

wiring in Chapter 3 and conduct the

wiring again.

Analog signal (GND)

from servo drive is

interfered

Check if the GND of analog signal is

misconnected to other signal.

Please refer to Chapter 3 and

conduct the wiring again. GND of

analog signal cannot be grounded

with other signals.

Causes Checking Method Corrective Actions

The motor is used for the

first time or the battery

had run dry but has

replaced a new one.

Check if the absolute coordinate

has been initialized.

Initialize the absolute coordinate.

Causes Checking Method Corrective Actions

Servo drive has not

completely written

barcode into encoder or

the encoder does not

complete the command

issued by servo drive.

Check if the wiring is correct or

there is any loose connection.

Correct the wiring.

Loading...

Loading...