ASDA-A2 Chapter 10 Troubleshooting

10-16 Revision February, 2017

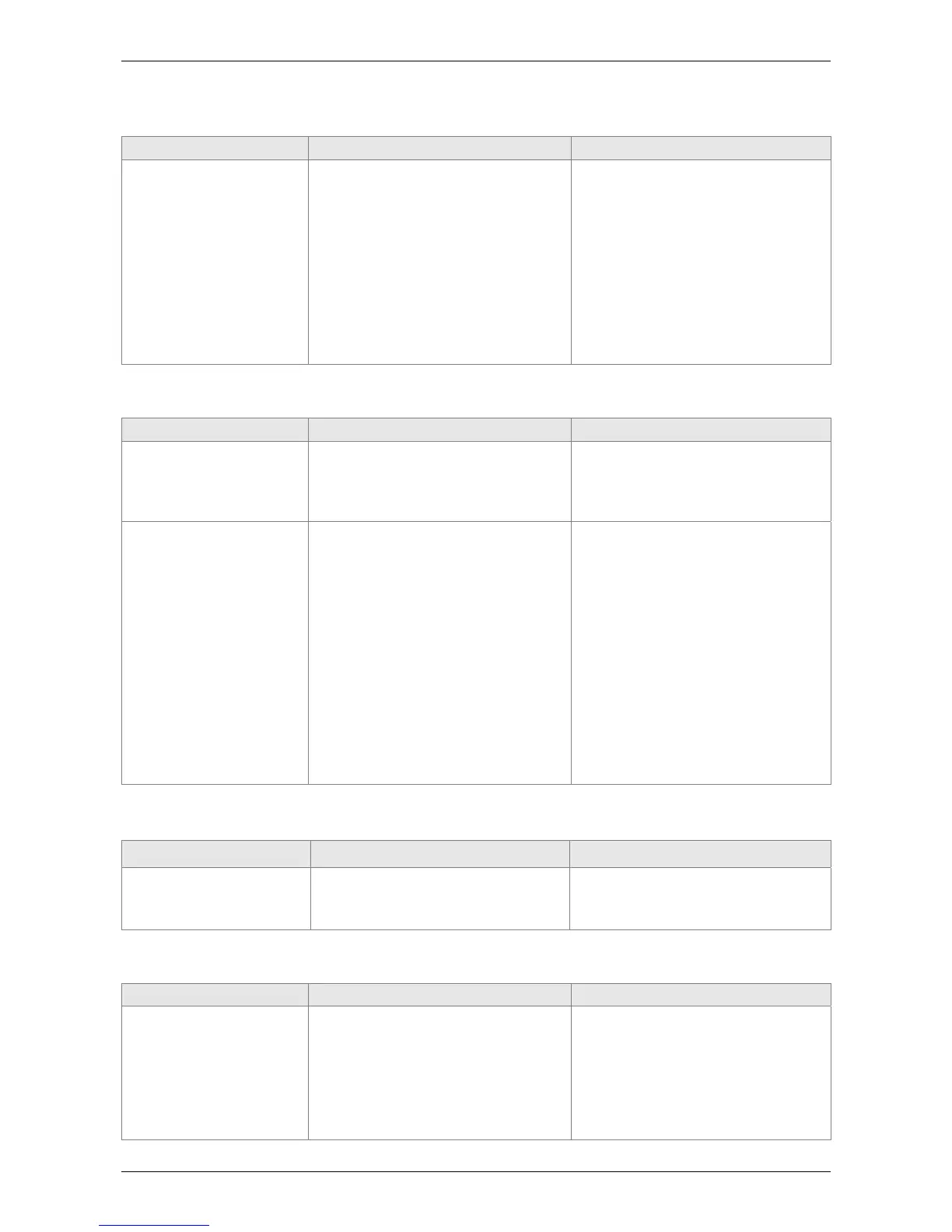

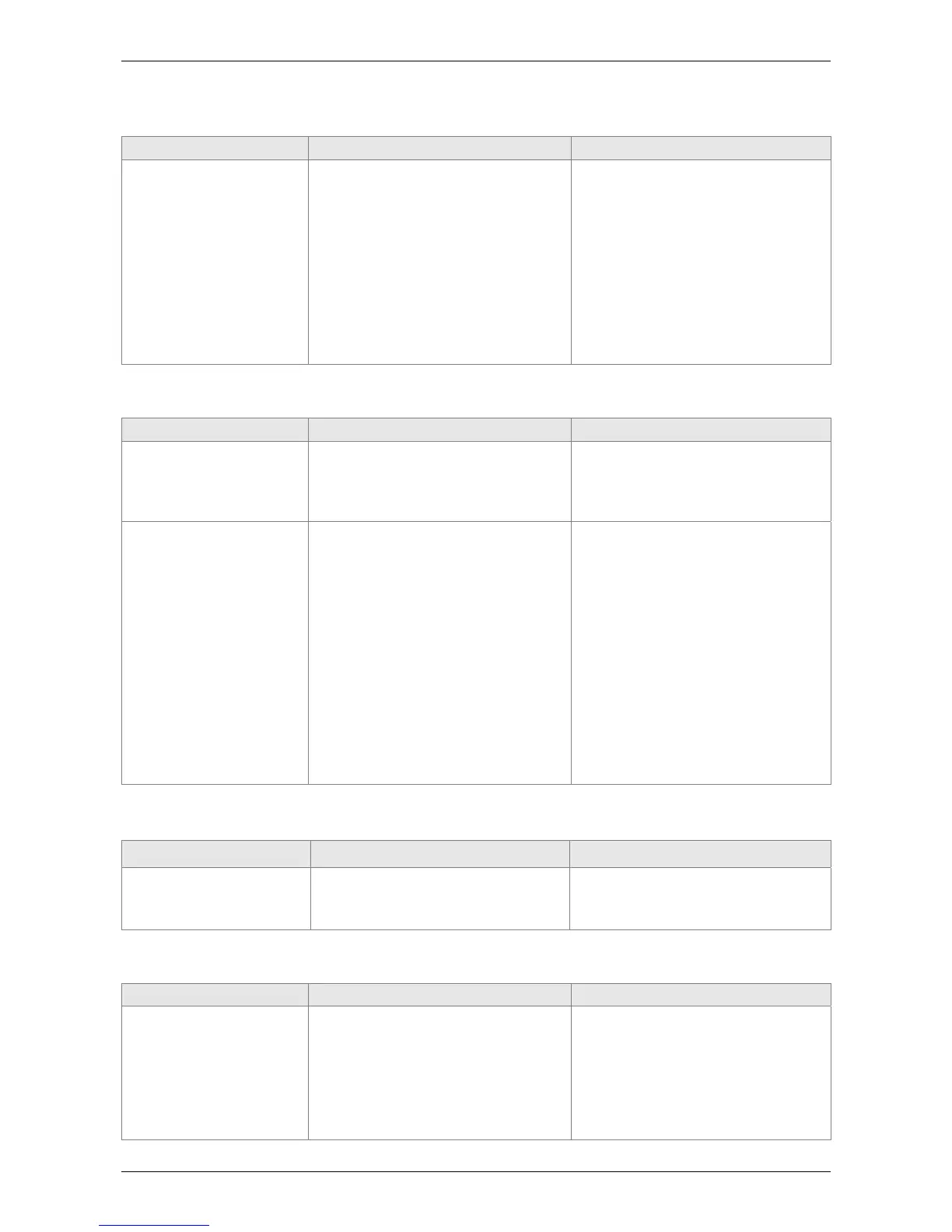

AL027:The internal of the motor is in error

Causes Checking Method Corrective Actions

The internal reset of the

encoder is in error.

1. Check if the servo is properly

grounded.

2. Check if the encoder cable

separates from the power supply

or the high-current circuit to avoid

the interference.

3. Check if the shielding cables are

used in the wiring of the

encoder.

1. Please connect the UVW

connector (color green) to the

heat sink of the servo drive.

2. Please check if the encoder

cable separates from the power

supply or the high-current circuit.

3. Please use shielding mesh.

4. If the situation is not improving,

please send the drive back to the

distributors or contact with Delta.

AL028:Encoder voltage error or the internal of the encoder is in error

Causes Checking Method Corrective Actions

Battery voltage is too

high

1. Check if the charging circuit

exists in the servo drive.

2. Check if the battery is correctly

installed

According to the procedure of Over

voltage to check. When corrective

actions are done, AL.028 will be

cleared automatically.

The internal encoder is in

error.

1. Check if it is the absolute type

encoder.

2. Check if the servo is properly

grounded.

3. Check if the encoder cable

separates from the power supply

or the high-current circuit to avoid

the interference.

4. Check if the shielding cables are

used in the wiring of the encoder.

1. If the situation is not improving,

please send the drive back to the

distributors or contact with Delta.

2. Please connect the UVW

connector (color green) to the

heat sink of the servo drive.

3. Please check if the encoder

cable separates from the power

supply or the high-current circuit.

4. Please use shielding mesh. If the

situation is not improving, please

send the drive back to the

distributors or contact with Delta.

AL029:Gray code error

Causes Checking Method Corrective Actions

Absolute position is in

error

Re-power on to operate the motor

and check if the alarm will occur

again.

If the alarm occurs again, please

change the encoder.

AL030:Motor Crash Error

Causes Checking Method Corrective Actions

Motor Crash Error

1. Check if P1-57 is enabled.

2. Check if P1-57 is set too small

and the time of P1-58 is set too

short.

1. If it is enabled by mistake, please

set P1-57 to zero.

2. According to the actual torque

setting, if the value is set too

small, the alarm will be triggered

by mistake. However, if the

value is set too big, it will lose

Loading...

Loading...