4A

Fig. 4A-

23

Fig.

4A-24

Fig.

4A-26

.

4A:

7

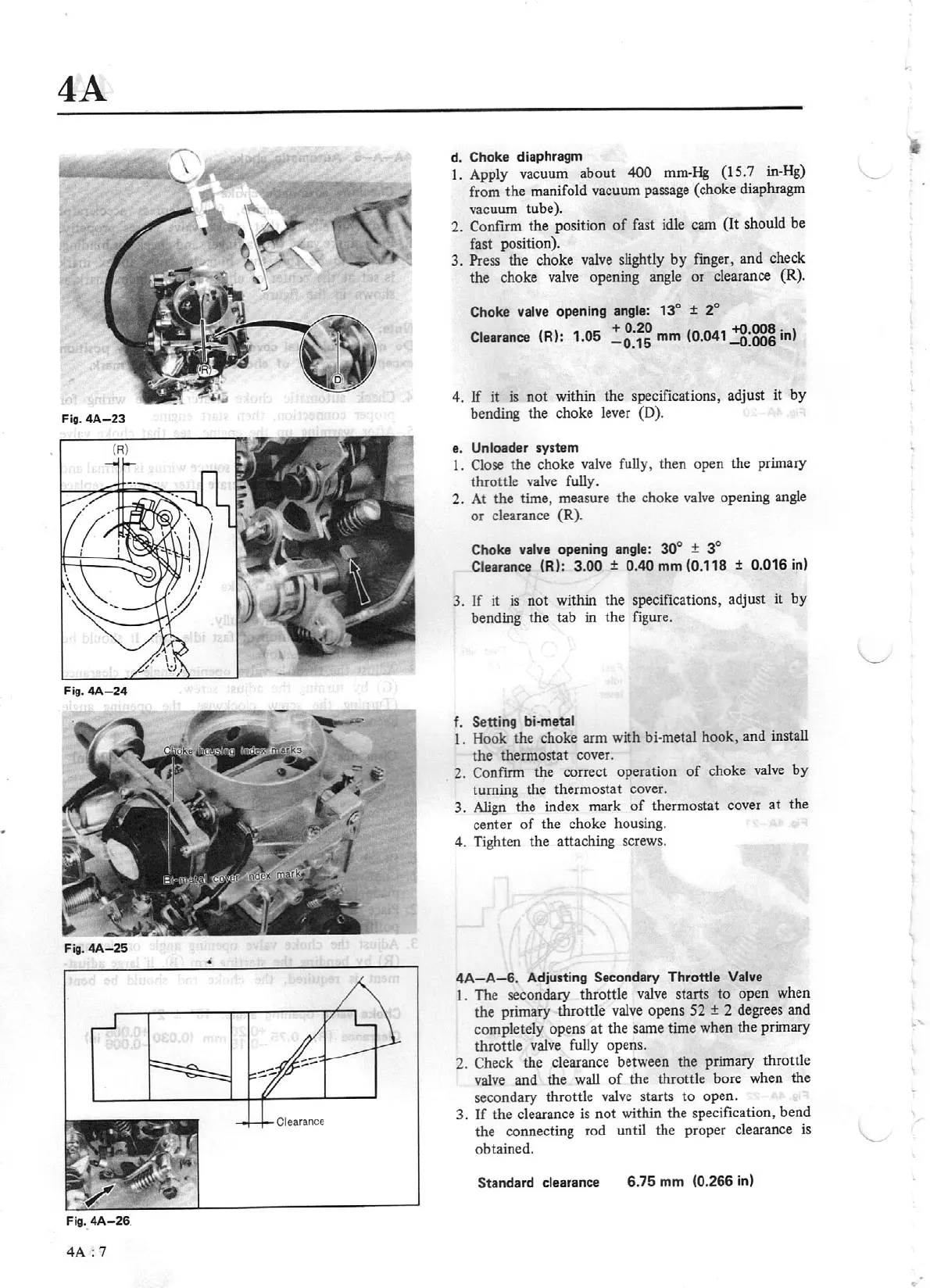

d. Choke diaphragm

1.

Apply vacuum about 400

mm-Hg (15.7 in-Hg)

from

the

manifold vacuum passage (choke diaphragm

va

cuum tube).

2. Confirm the position

of

fast idle cam (It should be

fast position).

3. Press the choke valve slightly

by

finger, and check

the choke

va

lve opening angle or clearance

(R)

.

Choke

valve

opening

angle: 13°

± 2°

Clearance

(R):

1.05

~g:~~

mm

(0

.041

~:~in)

4.

If

it

is

not

within the specifications, adjust

it

by

bending the choke lever (D).

e.

Unloader

system

1.

Close the choke

valve

fully, then open the primary

throttle valve fully.

2.

At the time, measure the choke valve opening angle

or

clearance (R).

Choke

val

ve

opening

angle:

30

°

±

3°

Clearance (R):

3.00

±

0.40

mm

(0.118

±

0.016

in)

3. If it

is

not within the specifications, adjust it

by

bending the tab in the figure.

f.

Setting bi-metal

1. Hook the choke arm with bi-metal hook, and install

the thermostat cover.

2. Confirm the correct operation

of

choke

valve

by

turning the thermostat cover.

3.

Align

the index mark of thermostat cover

at

the

center

of

the choke housing.

4. Tighten the attaching screws.

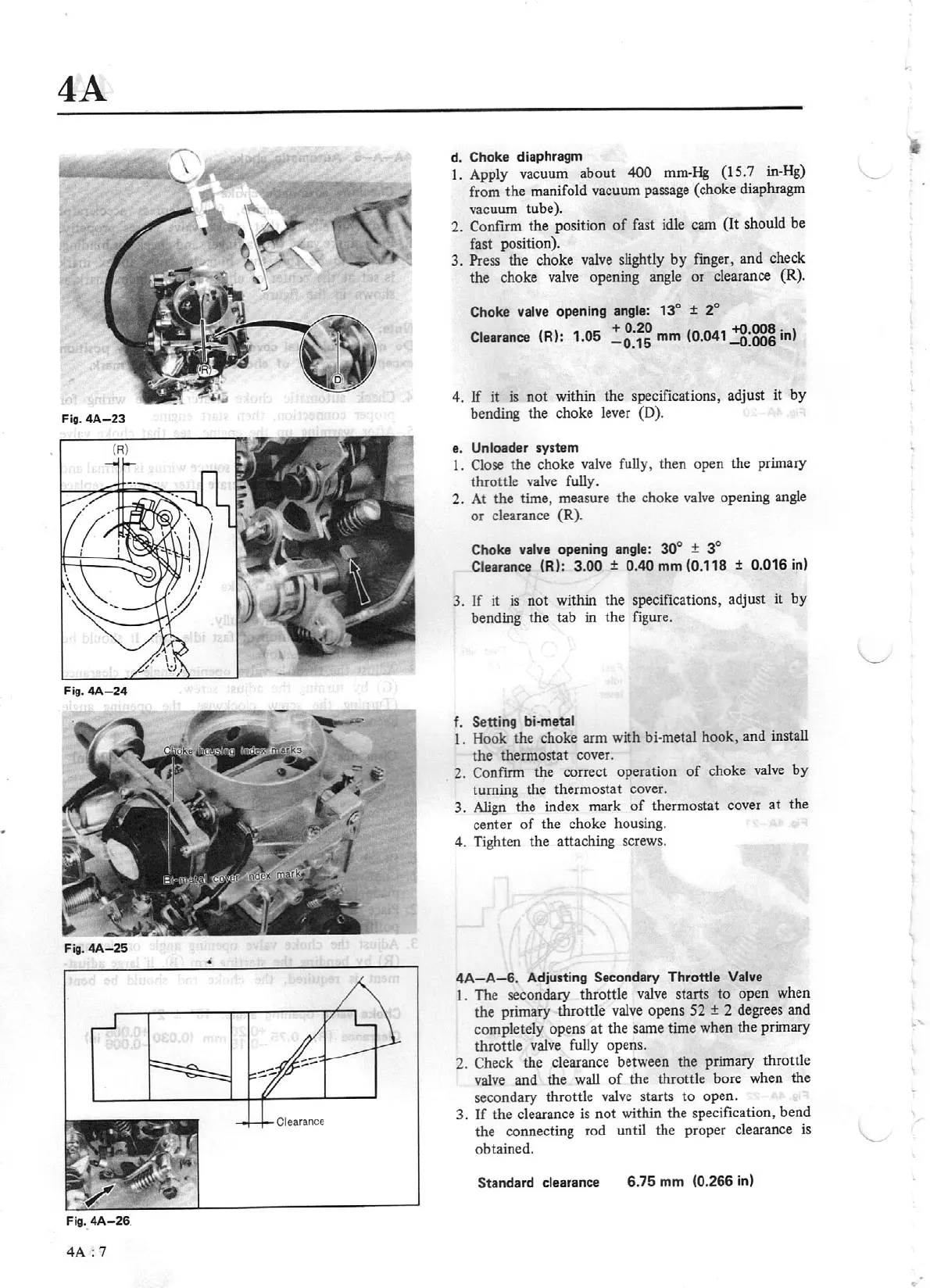

4A-A-6

. Adjusting Secondary Throttle Valve

1.

The secondary throttle

valve

starts

to

open when

the primary throttle valve opens 52

±

2 degrees and

completely opens at the same time when the primary

throttle valve

fully

opens.

2.

Check

the clearance between the primary

thr

ott

le

valve and the wall

of

the throttle bore when the

secondary throttle

valve

starts

to

open.

3.

If

the clearance

is

not

within the specification, bend

the connecting rod until the proper clearance

is

obtained.

Standard

clearance 6.

75

mm

(0.266 in)

Loading...

Loading...