7B

Fig.

78-17

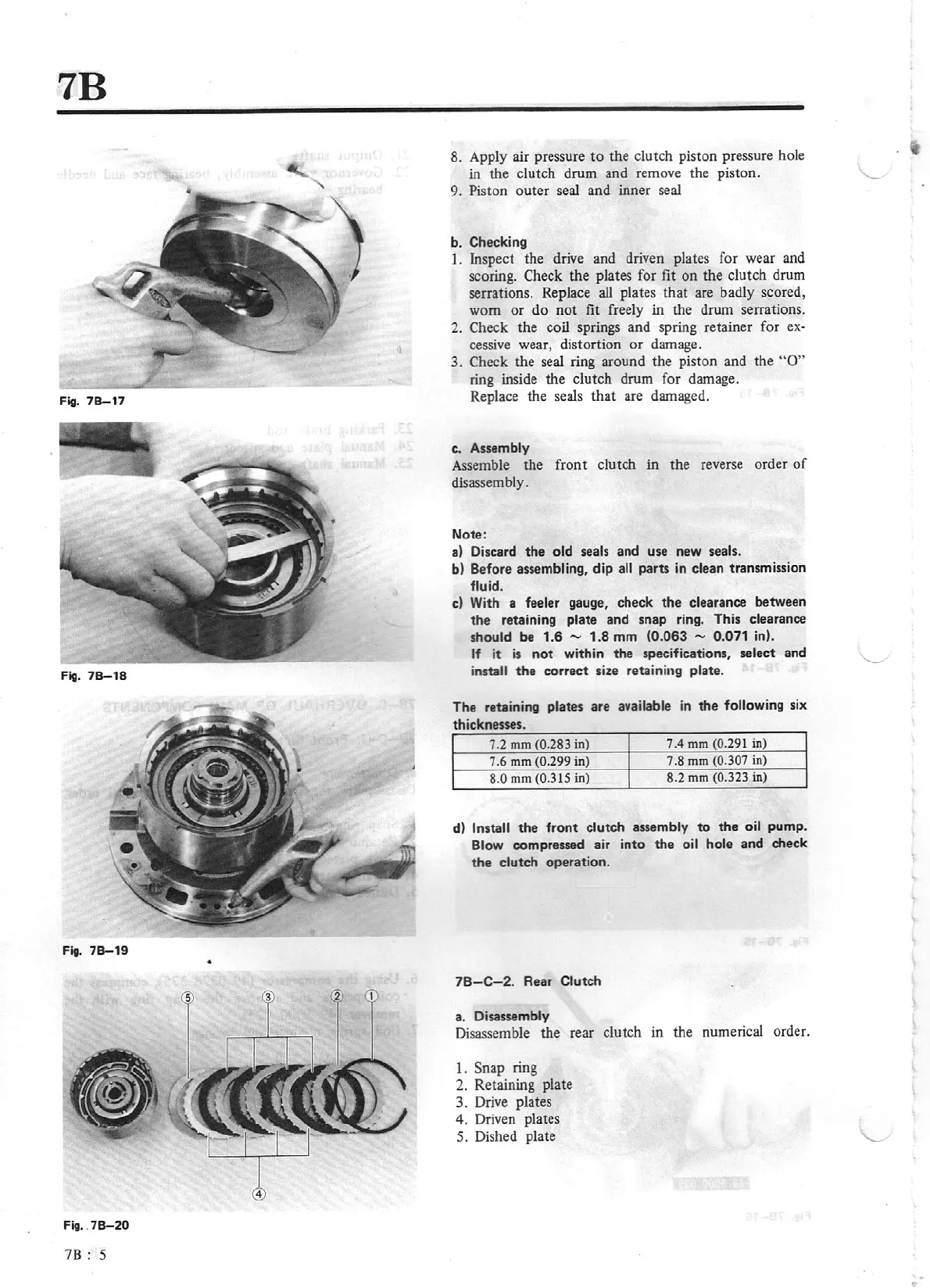

Fig.

78-18

Fig.

78-19

•

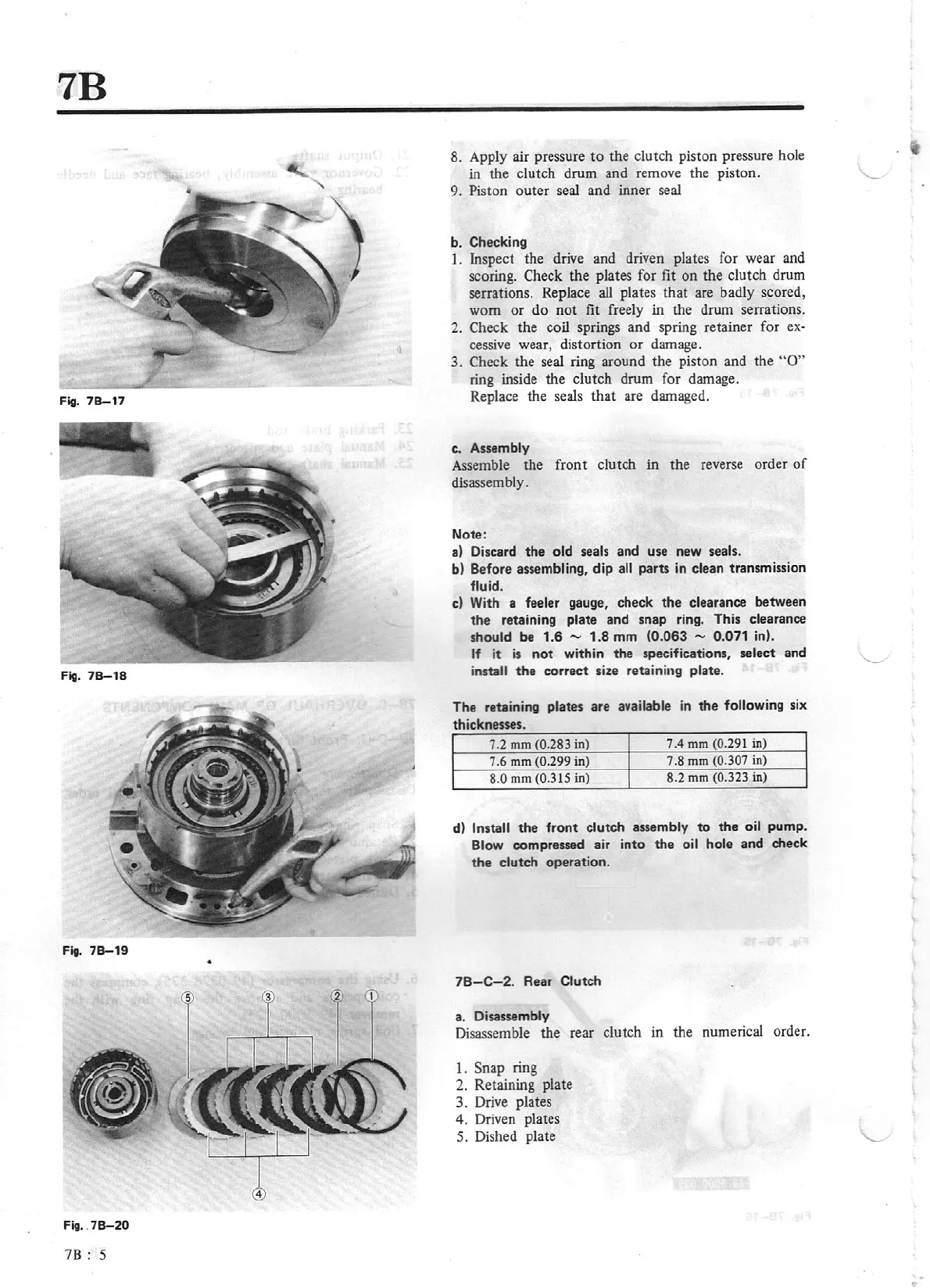

Fig.

78-20

78:

5

8. Apply air pressure

to

the clutch piston pressure hole

in the clutch drum and remove the piston.

\__

9. Piston outer

seal

and inner seal

b. Checking

1. Inspect the drive and driven plates for wear and

scoring. Check

th

e plates for fit

on

the clutch drum

serrations. Replace

all

plates

that

are badly scored,

worn

or

do

n

ot

fit freely in the drum serrations.

2. Check the coil springs and spring retainer for

ex·

cessive wear, distortion

or

damage.

3. Check the seal ring around the piston and the

"O"

ring inside the cl

ut

ch drum for damage.

Replace the

se

al

s that are damaged.

c. Assembly

Assemble the front cl

utch

in the reverse order

of

disassembly.

Note:

a)

Discard

the

old

sea

ls

and use new seals.

b) Before assembling, dip

all

parts in clean transmission

fluid.

c)

With a feeler gauge, check

the

clearance between

the

retaining plate and snap ring. This clearance

should be 1.6

-

1.8 mm

(0.063 - 0.071

in).

If

it

is

not

within the specifications, select and

install

the

correct size retaining plate.

The

retaining

plates are available

in

the

following six

thicknesses.

7.2

mm

(0.283

in)

7.4

mm

(0.291

in)

7.6

mm

(0.299

in)

7 .8

mm

(0.307

in)

8.0

mm

(0.315

in)

8.2

mm

(0.323

in)

d)

Install

the

front

clutch assembly

to

the

oil

pump.

Blow

compressed

air into the

oil hole and check

the

clutch operation.

78-C-2.

Rear Clutch

a. Disassembly

Disassemble the rear clutch in the numerical order.

1.

Snap

ring

2. Retaining plate

3. Drive plates

4. Driven plates

5. Dished plate

...

Loading...

Loading...