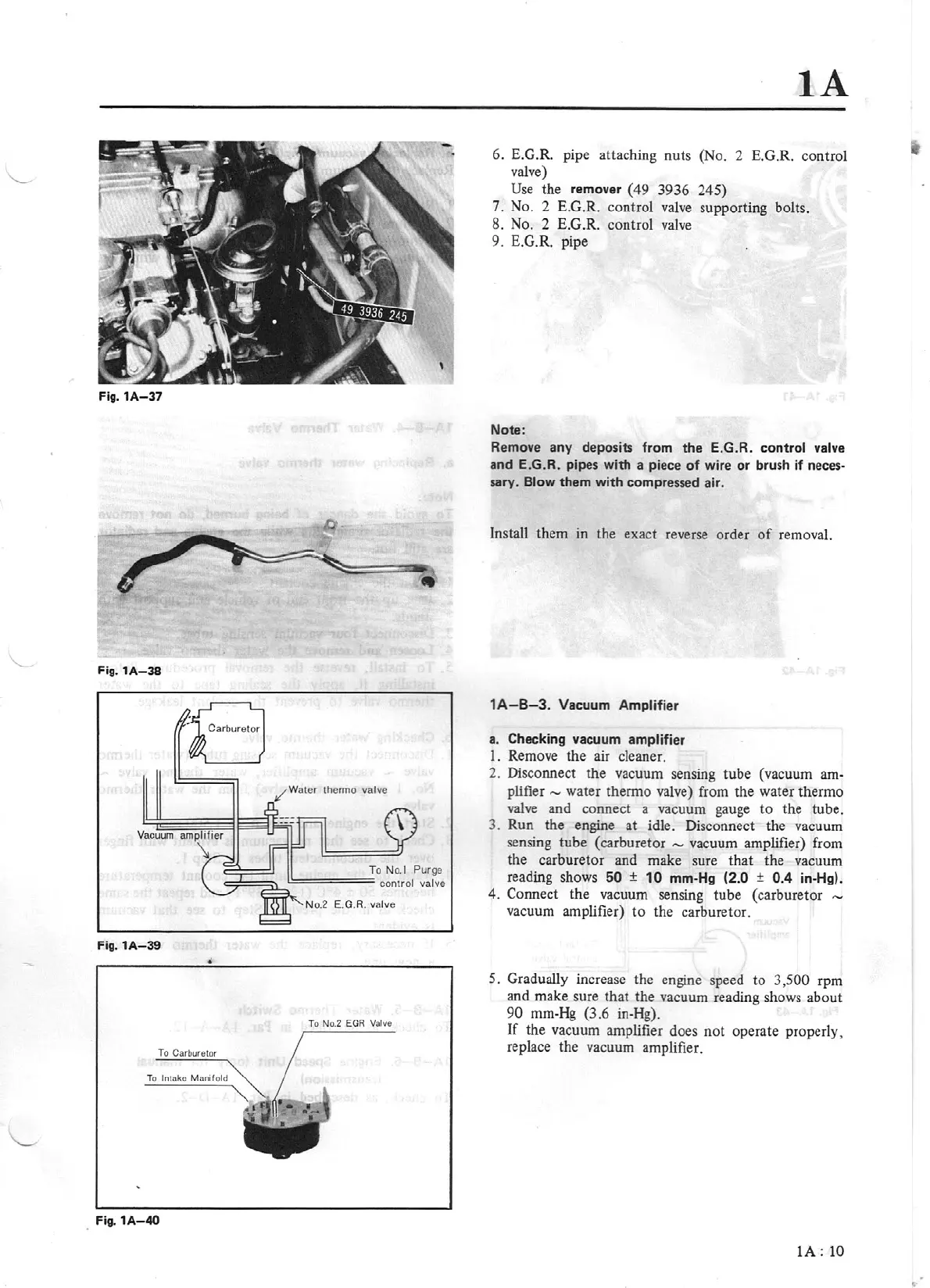

Flg.1A-37

Fig.

1A-38

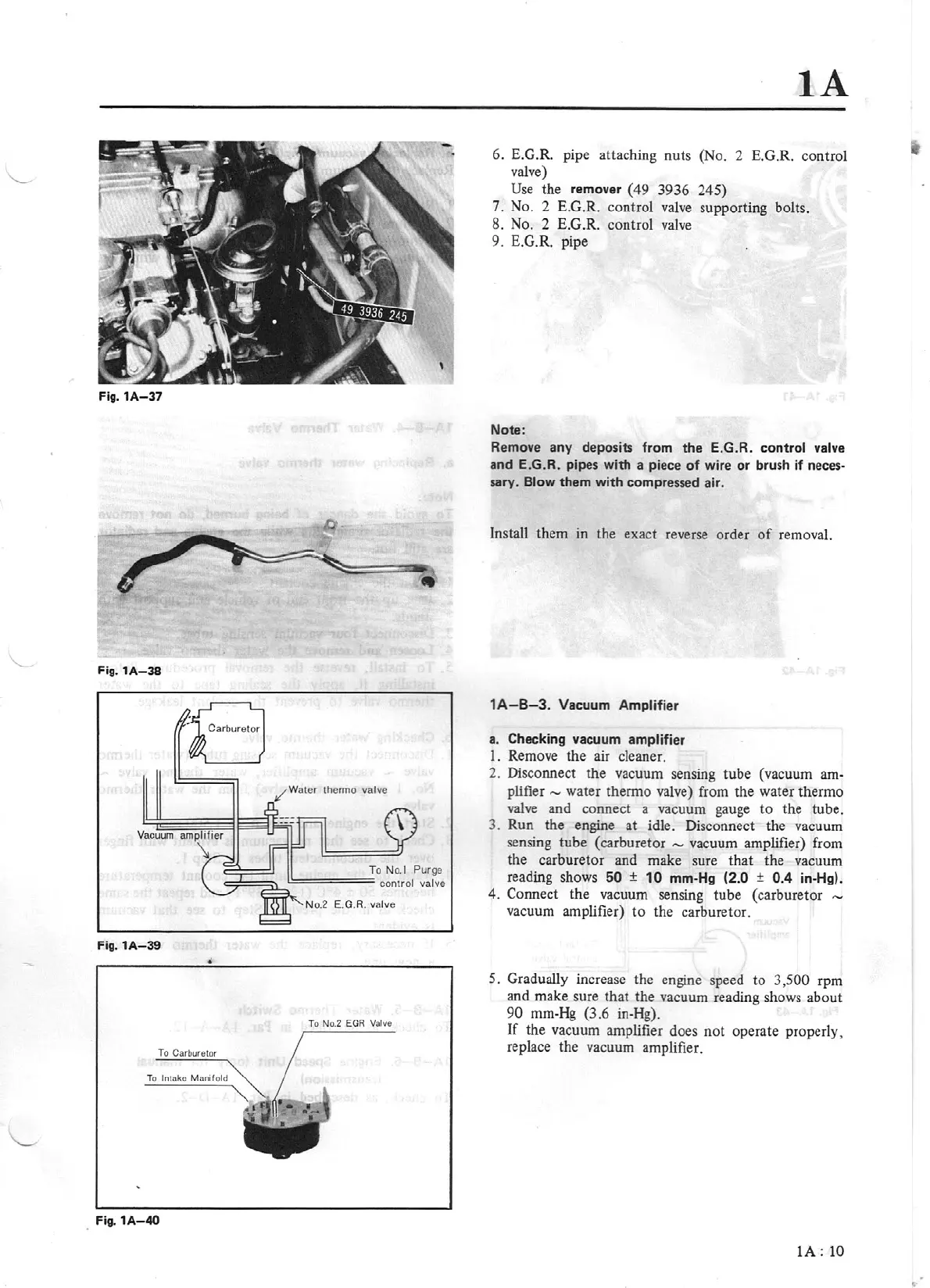

i/Water

thermo

valve

Fig.

1A-39

•

To

No.

2

ECl

A

Valve

To

CarbtXelOI

To

ln1

oko

M

orn

f

old

Fig.

1A-40

iA

6. E.G.R. pipe attaching nuts (No. 2 E.G.R. control

valve)

Use

the remover

(49

3936

245)

7.

No.

2

E.G.R. control valve supporting bolts.

8.

No.

2

E.G.R. control valve

9.

E.G.R. pipe

Note:

Remove any deposits from the E.G.R. control

valve

and E.G.R. pipes with a piece of wire or brush if

neces-

sary. Blow them with compres.sed air.

Install them

in

the exact reverse order

of

removal.

1A-B-3.

Vacuum

Amplifier

a. Checking vacuum amplifier

1. Remove the air cleaner.

2. Disconnect the vacuum sensing tube (vacuum

am-

plifier,....,

water thermo valve) from the water thermo

valve and connect a vacuum gauge

to

the tube.

3. Run the engine at idle. Disconnect the vacuum

se

nsing tube (carbur

etor

,....,

vacuum amplifier) from

the carburetor and make sure

that

the vacuum

reading shows

60

±

10

mm-Hg

(2.0 ±

0.4

in-Hg).

4. Connect the vacuum sensing tube (carburetor

vacuum amplifier)

to

the

carbur

eto

r.

5. Gradually increase the engine speed to 3

,

500

rpm

and make sure

that

the vacuum reading shows about

90

mm-Hg (3.6 in-Hg).

If

the vacuum amplifier does

not

operate properly,

replace the vacuum amplifier.

IA:

10

Loading...

Loading...