F

ig

.

1A

-

58

Fig.1A

-

59

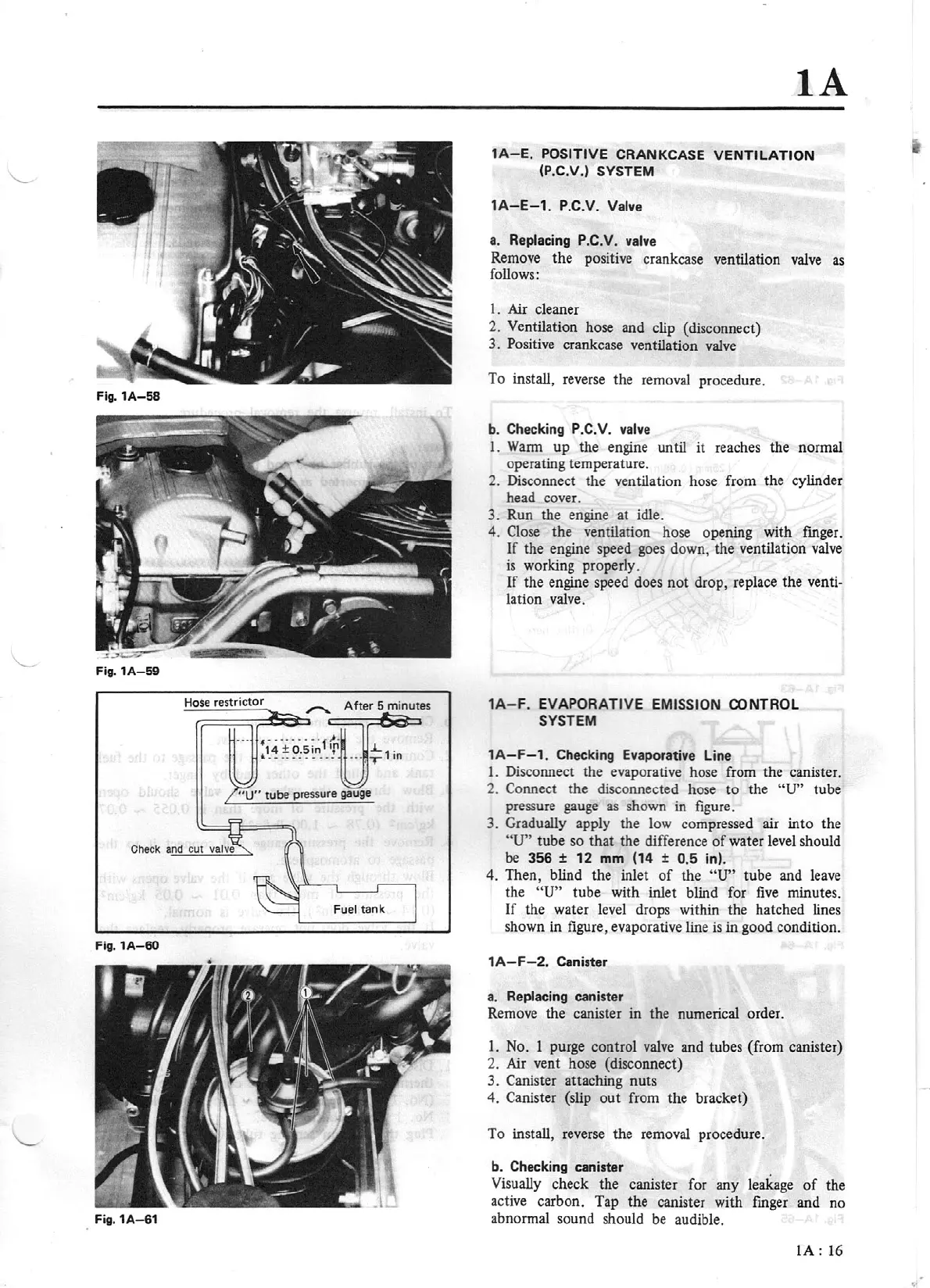

Hose restrictor

Fig.1A-60

Fig.1A-61

lA

1A-E.

POSI

T

IVE

CRANKCASE VENTI LATION

(P.C.V.) SYSTEM

1A-E-1.

P.C.V. Valve

a. Replacing P.C.V. valve

Remove

the

positive crankcase ventilation valve as

follows :

1.

Air cleaner

2. Ventilation hose and clip (disconnect)

3. Positive crankcase ventilation valve

To install, reverse the removal procedure.

b. Checking

P.C

.

V.

valve

I.

Wann up the engine until

it

reaches the normal

operating temperature.

2. Disconnect the ventilation hose from the cylinder

head cover.

3.

Run the engine at idle.

4. Close the ventilation hose opening with finger.

If

the engine speed goes down, the ventilation valve

is

working properly.

If

the engine speed does

not

drop, replace the venti-

lation valve.

1A-F.

EVAPORATIVE EMISSION CONTROL

SYSTEM

lA-F

- 1. Checking Evaporative Line

1.

Disconnect the evaporative hose from the canister.

2.

Connect the disconnected hose

to

the

"U"

tube

pressure gauge

as

shown in figure.

3. Gradually apply the low compress

ed

air into the

"U"

tube so that the difference

of

water level should

be

356

±

12

mm (14 ±

0.5

in).

4.

Then, blind the inlet

of

the

"U"

tube and leave

the

"U"

tube with inlet blind for

five

minutes.

If the water level drops within the hatched lines

shown in figure, evaporative line

is

in good condition.

lA

-

F-2.

Canister

a. Replacing canister

Remove the canister in the numerical order.

1. No. 1 purge control valve and tubes (from canister)

2. Air vent hose (disconnect)

3. Canister attaching nuts

4.

Canister (slip

out

from the bracket)

To install, reverse the removal procedure.

b. Checking canister

Visually check the canister for any leakage

of

the

active carbon. Tap the canister with finger and no

abnormal sound should

be

audible.

lA:

16

Loading...

Loading...