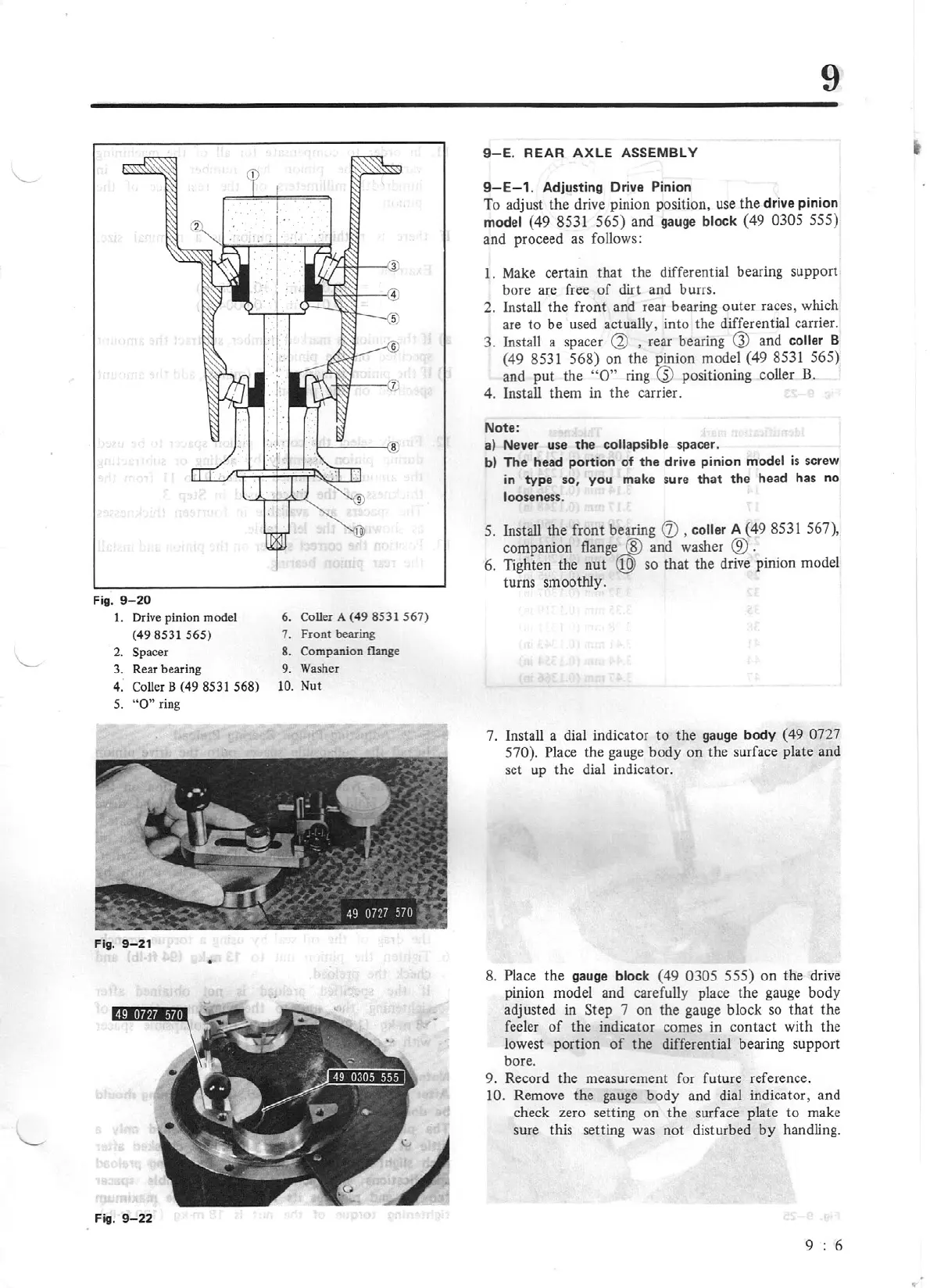

Fig. 9-

20

I.

Drive pinion model 6. Coller A

(49

8531 567)

(49 8531 565)

7.

Front bearing

2.

Spacer

8. Companion flange

3.

Rear beari

ng

9.

Washer

4. Coller B (49 8531 568)

1

0.

Nut

5.

"O"

ring

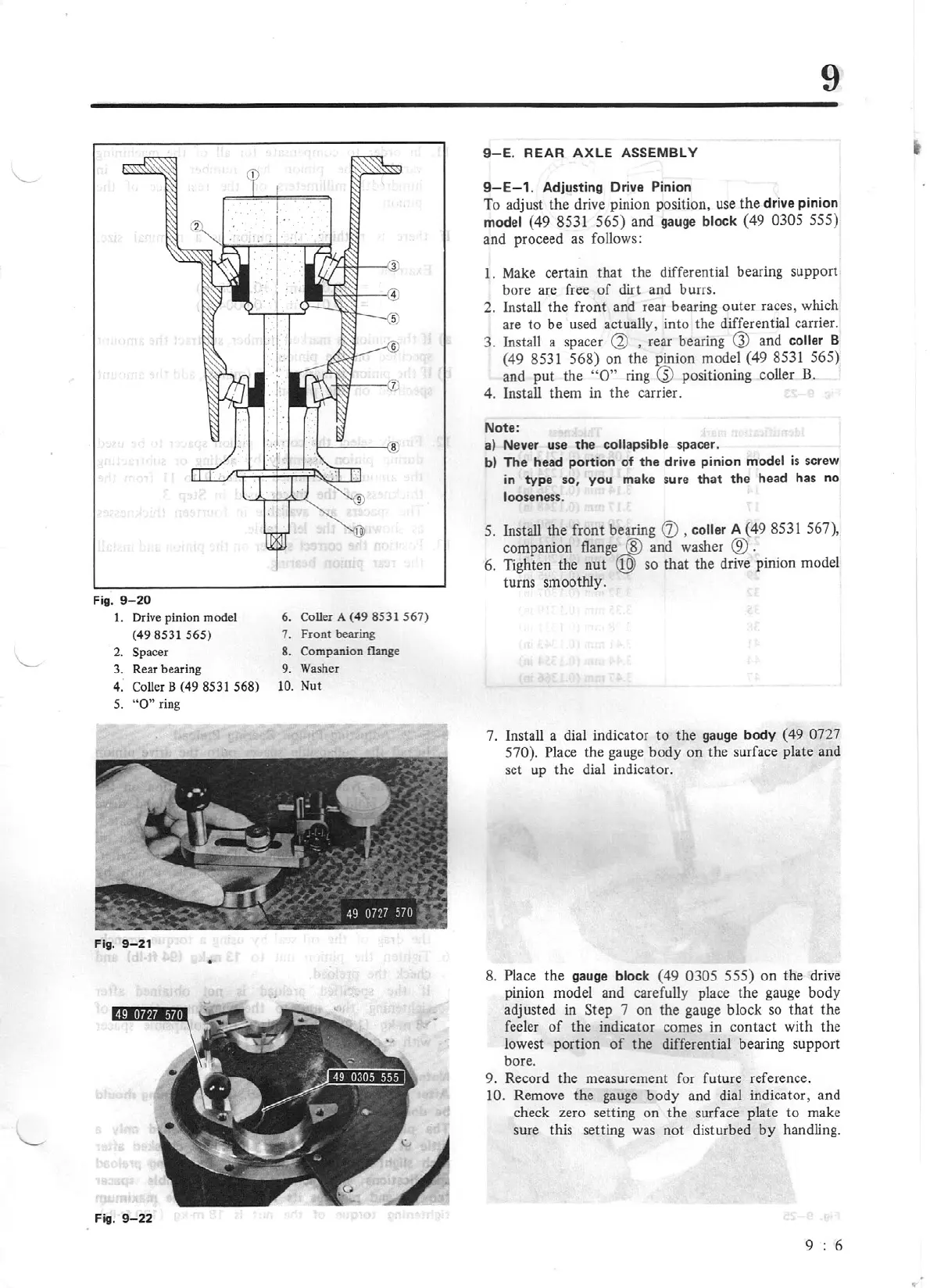

Fig.

9-21

•

Fig.

9-

22

9

9-E

. REAR AXLE

ASSEMBLY

9-E-1

.

Adjusting Drive Pinion

To adjust the drive

pinion

position, use

the

d

rive

pinion

model

{49

8531 565)

and gauge block {49

0305

555)

and proceed as follows:

1. Make certain

that

the differential bearing support

bore arc free

of

dirt and burrs.

2. Install

the

front and rear bearing outer races, which

are

to

be used actually, into the differential carrier.

3. Install a spacer

~

, rear bearing

G)

and

collar

B

(49

8531

568)

on the pinion model (49

8531 565)

and

put

the

"O"

ring

~

positioning coller

B.

4. Install them in the carrier.

Note:

a)

Never use

the

collap

si

ble

spacer.

b) The head portion of the drive pinion

model

is

screw

in

type

so, you make sure

that

the head has no

looseness.

5.

Install the front bearing

Q)

,

coller

A (49

8531

567),

companion

flange...@

and washer

®

.

6. Tighten the

nut

Q9)

so

that

the drive pinion model

turns smoothly.

7. Install a dial indicator to the gauge body ( 49

0727

570).

Place

the gauge body

on

the surface plate and

set up the dial indicator.

8.

Place

the gauge

block

(49

0305 555)

on

the drive

pinion model and carefully place the gauge body

adjusted in Step 7 on the gauge block so that the

feeler

of

the indicator comes

in

contact with the

lowest portion

of

the differential bearing support

bore.

9. Record the measurement for future reference.

10.

Remove the gauge body and dial indicator, and

check zero setting on the surface plate

to

make

sure this setting was not disturbed

by

handling.

9 6

...

Loading...

Loading...