Fig,

4A-35

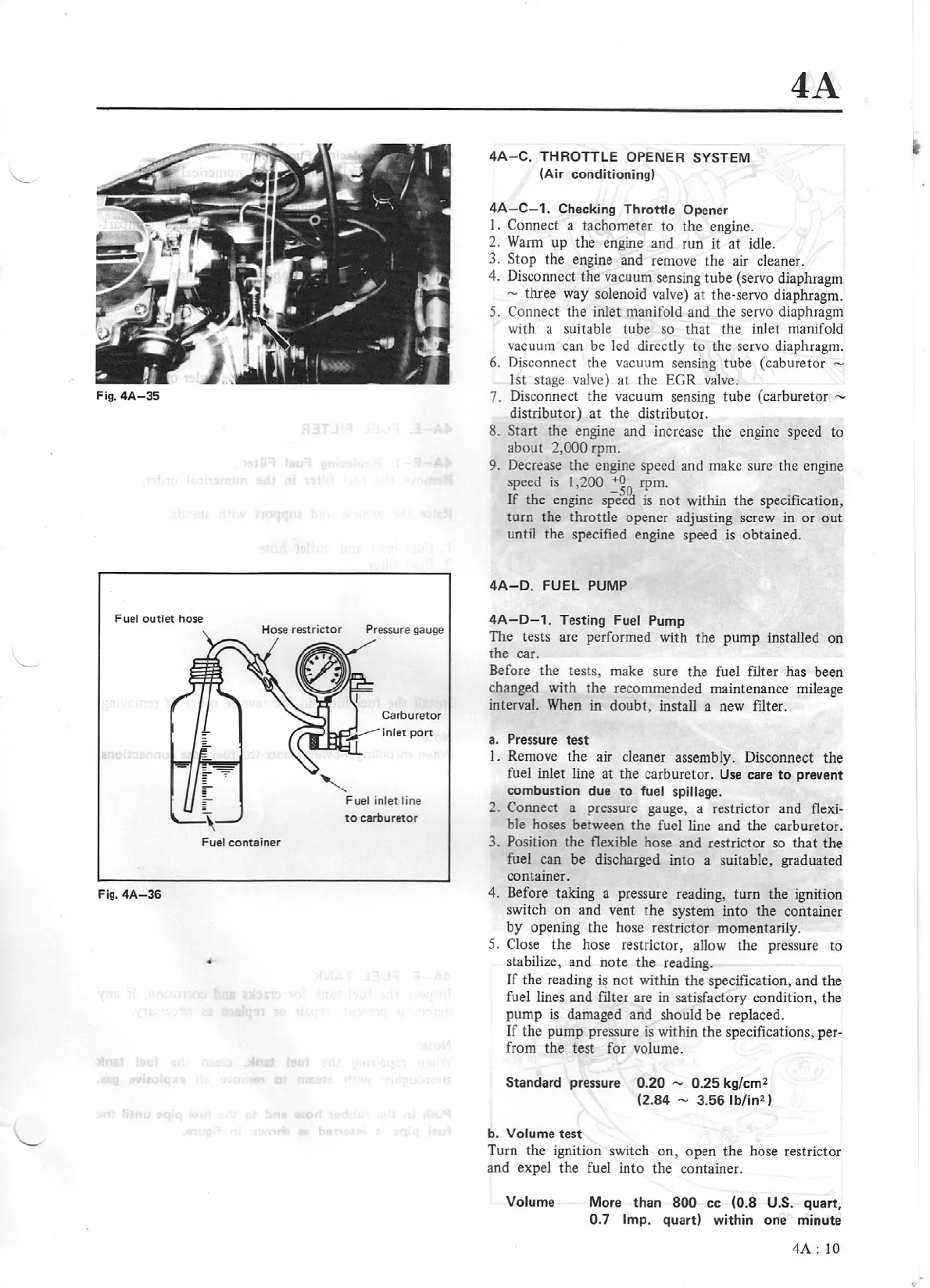

Fuel

outlet

hose

Fuel

container

Fig.

4A-36

Pressure gauge

Carburetor

Fuel

inlet

line

to

carburetor

4A-C

. THROTTLE OPENER SYSTEM

(Air conditioning)

4A-C-1.

Checking Throttle Opener

1 . Connect a tachometer to the engine.

2. Warm

up

the engine and run it at idle.

4A

3. Stop the engine and remove the air cleaner.

4. Disconnect the vacuum sensing tube (servo diaphragm

~

three way solenoid valve) at the·servo diaphragm.

5.

Connect the inlet manifold and the servo diaphragm

with a suitable tube so that the inlet manifold

vacuum can be led directly to the servo diaphragm.

6. Disconnect the vacuum sensing tube (caburetor

~

1st stage valve) at the

EGR

valve

.

7. Disconnect the vacuum sensing tube (carburetor -

distributor) at the distributor.

8. Start the engine and increase the engine speed to

about 2,000 rpm.

9. Decrease the engine speed and make sure the engine

speed

is

1,200 j

0

rpm.

If

the engine speea

is

not

within the specification,

turn

the throttle opener adjusting screw

in

or

out

until the specified engine speed

is

obtained.

4A

-D

. FUEL

PUMP

4A-D-1.

Testing Fuel Pump

The tests are performed with the pump installed

on

the car.

Before the tests, make sure

the

fuel filter has been

changed with the recommended maintenance mileage

interval. When in doubt, install a new filter.

a. Pressure test

1. Remove the air cleaner assembly. Disconnect the

fuel inlet line at the carburetor. Use care

to

prevent

combustion due

to

fuel spillage.

2. Connect a pressure gauge, a restrictor and flexi-

ble hoses between the fuel line and the carburetor.

3. Position the flexible hose and restrictor so

that

the

fuel can be discharged into a suitable, graduated

container.

4.

Before taking a pressure reading, turn the ignition

switch on and vent the system into the container

by

opening the hose restrictor momentarily.

5. Close the hose restrictor, allow the pressure to

stabilize, and note the reading.

If

the reading

is

not

within the specification, and the

fuel lines and filter are in satisfactory condition, the

pump

is

damaged and should be replaced.

If

the pump pressure

is

within the specifications, per-

from the test for volume.

Standard pressure

0.20

-

0.25

kg/cm2

(2.84

~

3.56

lb/in2)

b. Volume test

Turn the ignition switch

on,

open the hose restrictor

and expel the fuel into the container.

Volume

More

than

800

cc

(0.8 U.S.

quart,

0.7 Imp. quart) within

one

minute

4A :

IO

•.

Loading...

Loading...