7A

Fig.

7A

- 17

Fig.

7A-18

Fig.

7A-19

•

Fig.

7A

-

20

7A:

5

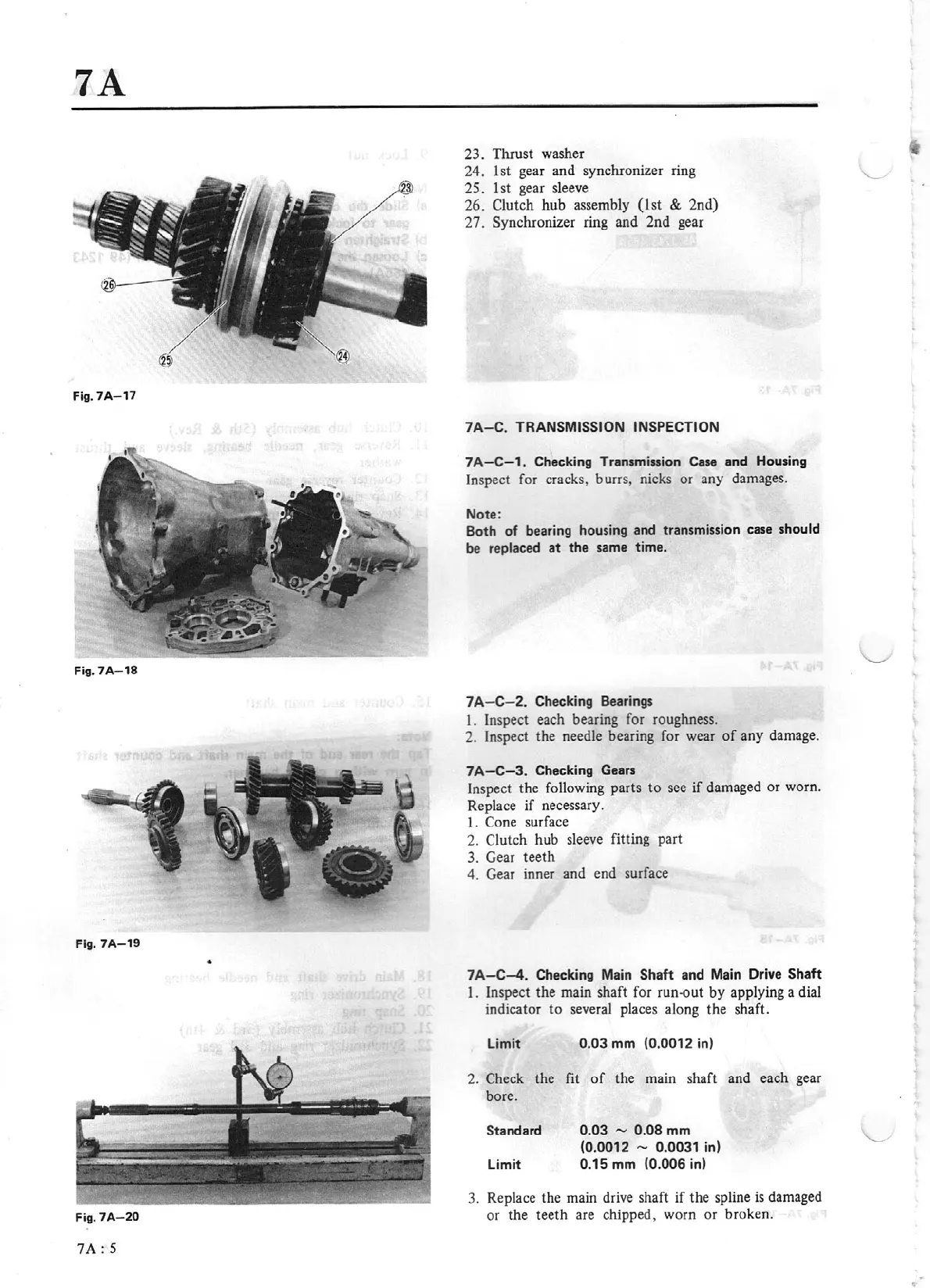

23. Thrust washer

24.

lst

gea

r and synchronizer ring

25. 1st gear sleeve

26. Clutch hub assembly

(I

st

&

2nd)

27.

Syncluonizer

ring and 2nd gear

7A-C.

TRANSMISSION INSPECTION

7A-C-1.

Checking Transm

iu

ion

Case

and Housing

In

spect for cracks, burrs, nicks or any damages.

Note:

Both

of

bearing housing and transmission

case should

be

replaced

at

the

same time.

7A- C- 2. Checking Bearings

I.

Inspect each bearing for roughness.

2. Inspect the needle bearing for wear

of

any damage.

7A-C-3.

Checking Gears

Inspect the following parts

to

see

if

damaged or worn.

Replace

if

necessary.

l . Cone surface

2. Clutch hub sleeve fitting part

3. Gear teeth

4. Gear inner and end surface

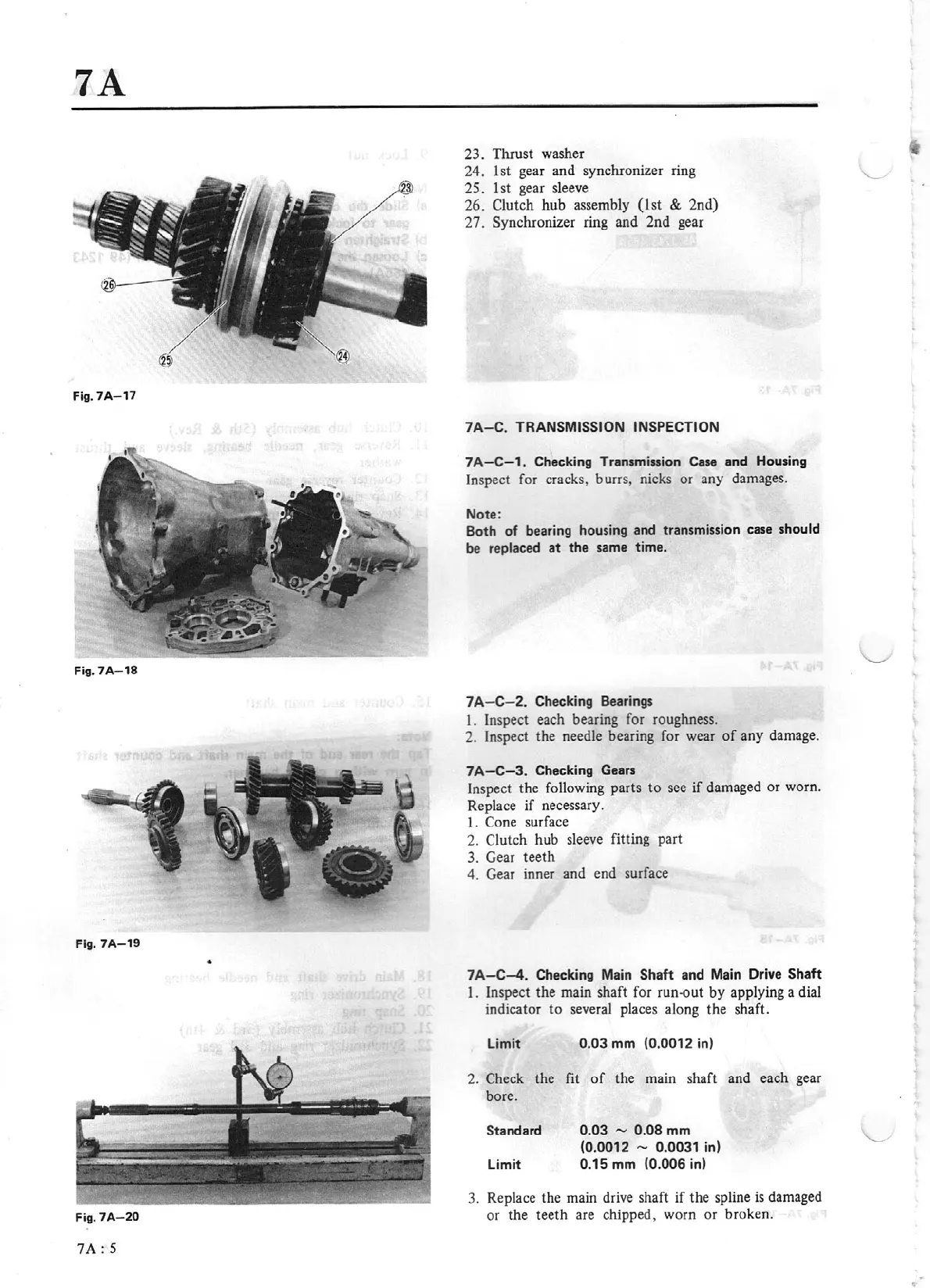

7

A-C-4

. Checking Main

Shaft

and

Main

Drive

Shaft

1. Inspect the main shaft for

run-out

by

applying a dial

indicator

to

several places along the shaft.

Limit

0.

03

mm

(0.0012

in)

2. Check the fit

of

the main shaft and each gear

bore.

Standard

Limit

0.03

,..,,,

0.08

mm

(0.0012

,..,,,

0.0031

in)

0.15

mm

(0.006

in)

3. Replace the main drive shaft

if

the spline

is

damaged

or

the teeth are chipped, worn or broke

n.

Loading...

Loading...