11

F

ig

. 11-

47

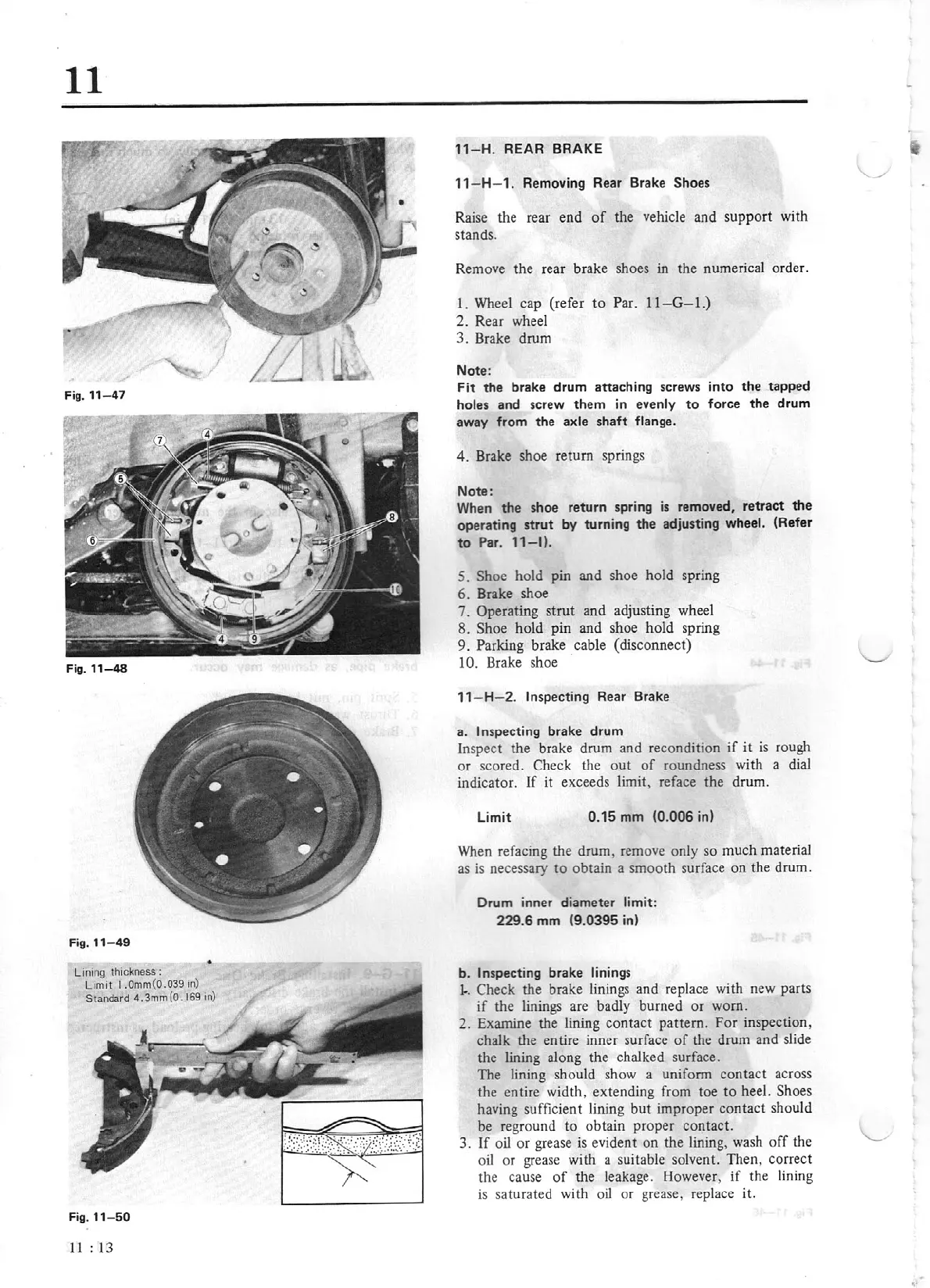

Fig. 11

-48

Fig.

11-49

·

~-----

L1111

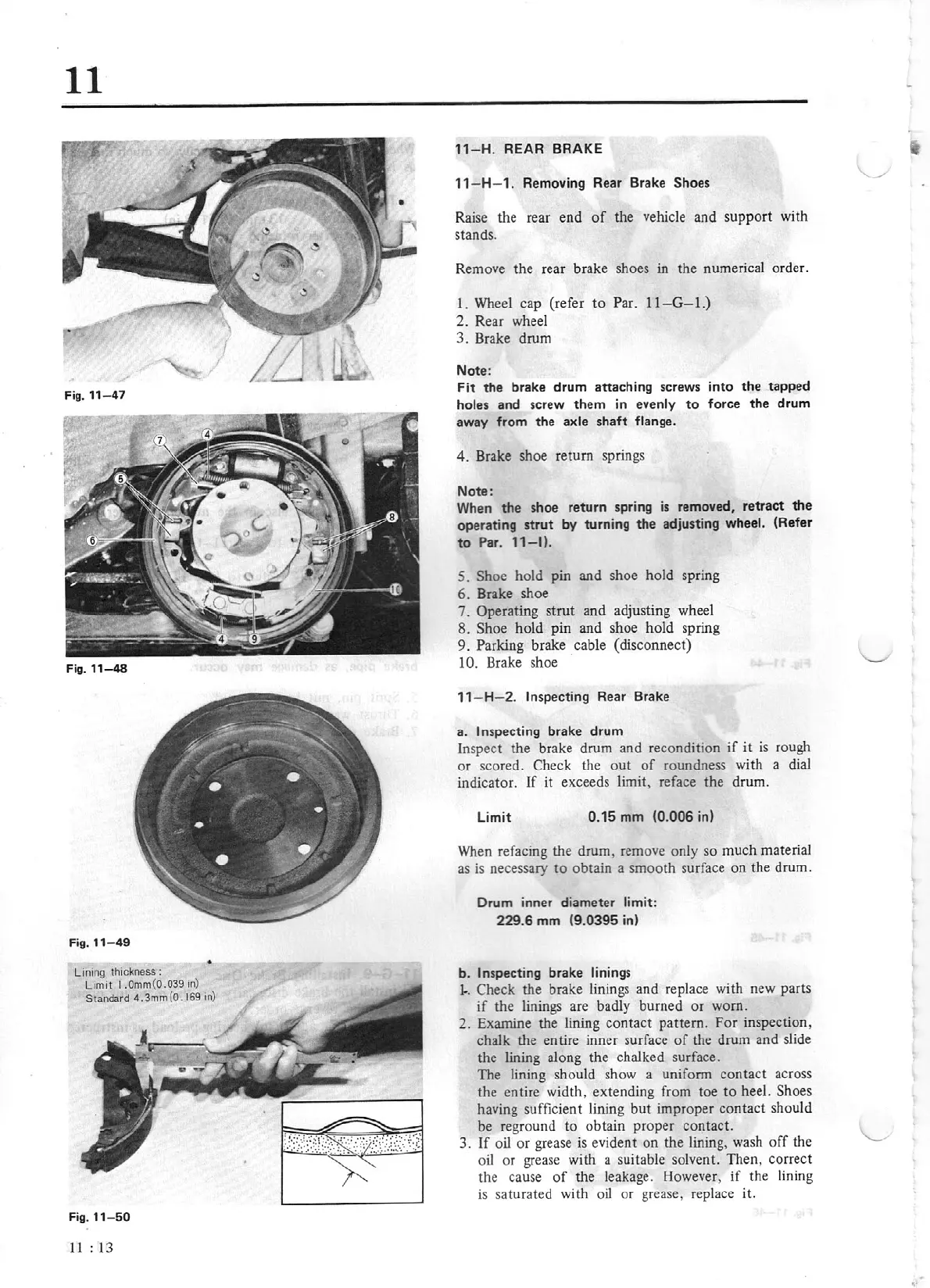

ng thickness :

Limit I .

Omm

(0

.039

in)

Standard

4.3mm

(0 . 1

69

in)

Fig.

1

1-50

11

:

13

11

-

H.

REA

R

BRAKE

11

- H- 1.

Removing Rear Brake

Shoes

Raise

the rear end

of

the vehicle and support with

stands.

Remove the rear brake shoes

in

the numerical order.

l.

Wheel

cap (refer to

Par.

11-G

-

1.

)

2.

Rear wheel

3.

Brake drum

Note:

Flt

the brake drum attaching scr

ews

into the tapped

holes and screw them in evenly

to

force

th

e dr

um

away from the axle shaft flan

ge.

4.

Brake shoe return springs

Note:

When

the shoe return spring

is

re

moved, retract the

operating str

ut

by turning the adjusting whe

el

. (Refer

to

Par.

11-1

).

5.

Shoe hold pin and shoe hold spring

6.

Bra

ke shoe

7.

Operating strut and

ad

ju

sting wheel

8.

Shoe

hold

pin and shoe hold spring

9.

Parking

brake cable (disconnect)

10.

Brake shoe

11

- H- 2.

In

specti

ng

Rear Brake

a.

Ins

pecting

br

ake drum

Inspect the brake drum and recondition if it

is

rough

or scored. Check the out

of

roundness

wi

th a dial

indicator.

If

it exceeds

limit,

reface the drum.

Limit

0.15

mm

10.006

in

)

When

refacing the drum, remove only so much materiaJ

as

is

necessary

to

obtain a smooth surface on the d

ru

m.

Dru

m

in

ne

r dia

me

ter limit:

2.

29

.6

mm

(9.0395

in)

b. Inspecti

ng

brake

lin

i

ng

s

J..

Check

the brake linings and replace with

new

parts

if

the linings are badly burned or worn.

2.

Examjne the lining contact pattern. For inspec

ti

on,

chaJk

the entire inner sur

face

of

the drum and s

li

de

the lining along the chalked surface.

The lining should show a unifonn contact acr

oss

the entire width, extending from toe

to

he

el.

Shoes

having sufficient lining but improper contact should

be

reground to obtain proper contact.

3.

If

oil

or grease is evident on the

li

ning,

was

h off

th

e

oil

or

grease

with a suitable solvent. Then, correct

the cause

of

the leakage. However,

if

the l

in

i

ng

is

saturated with o

il

or grease, replace

it.

Loading...

Loading...