Fig.

1-55

Fig, 1-

56

Fig.

1-57

Fig.

1-

58

1

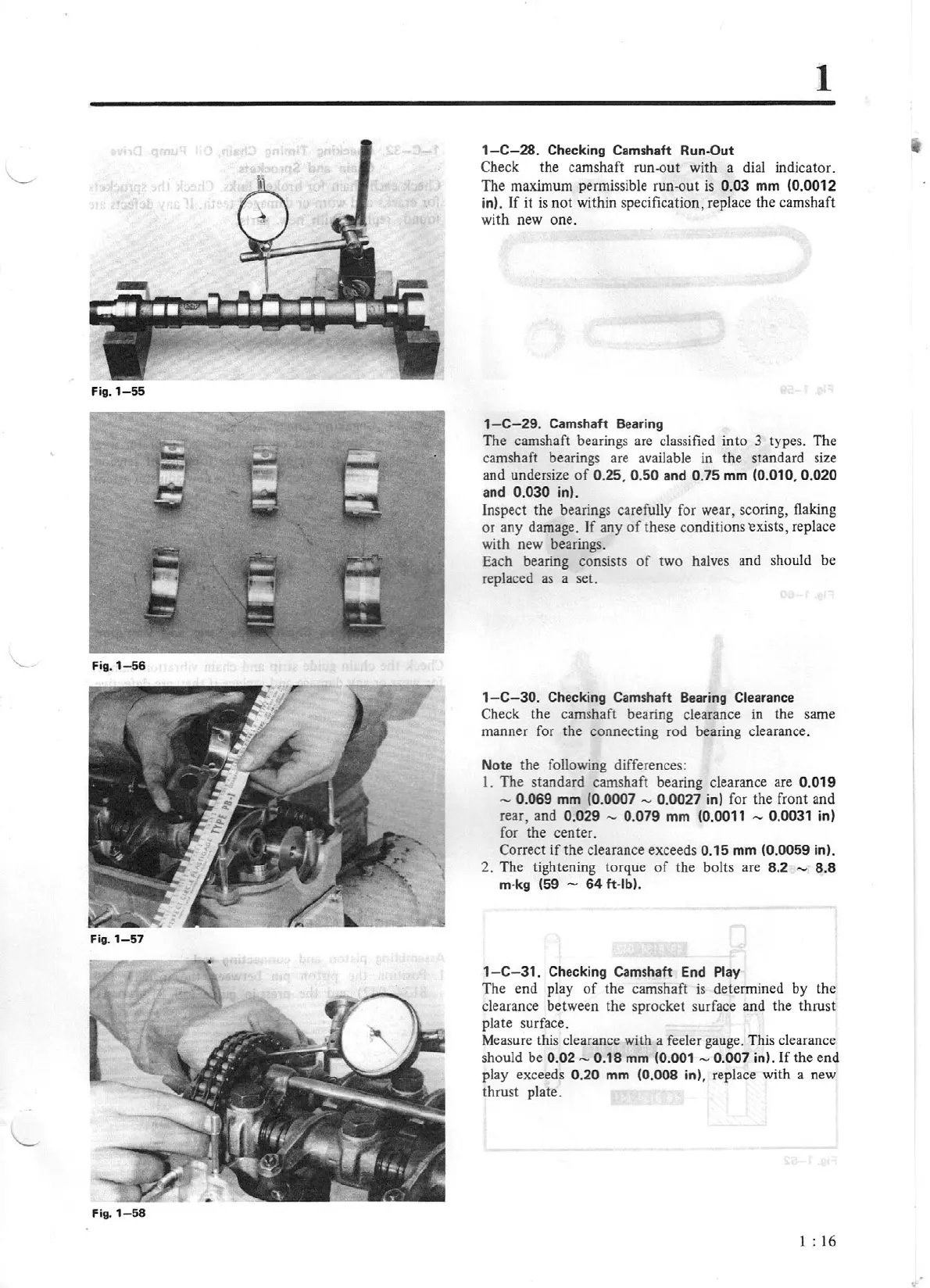

1-C-28.

Checking

Camshaft

Run-Out

Check the camshaft run-0ut with a dial indicator.

The maximum permissible run-

out

is

0.

03

mm

(0.0012

in).

If

it

is

not

within specification, replace

the

camshaft

with new one.

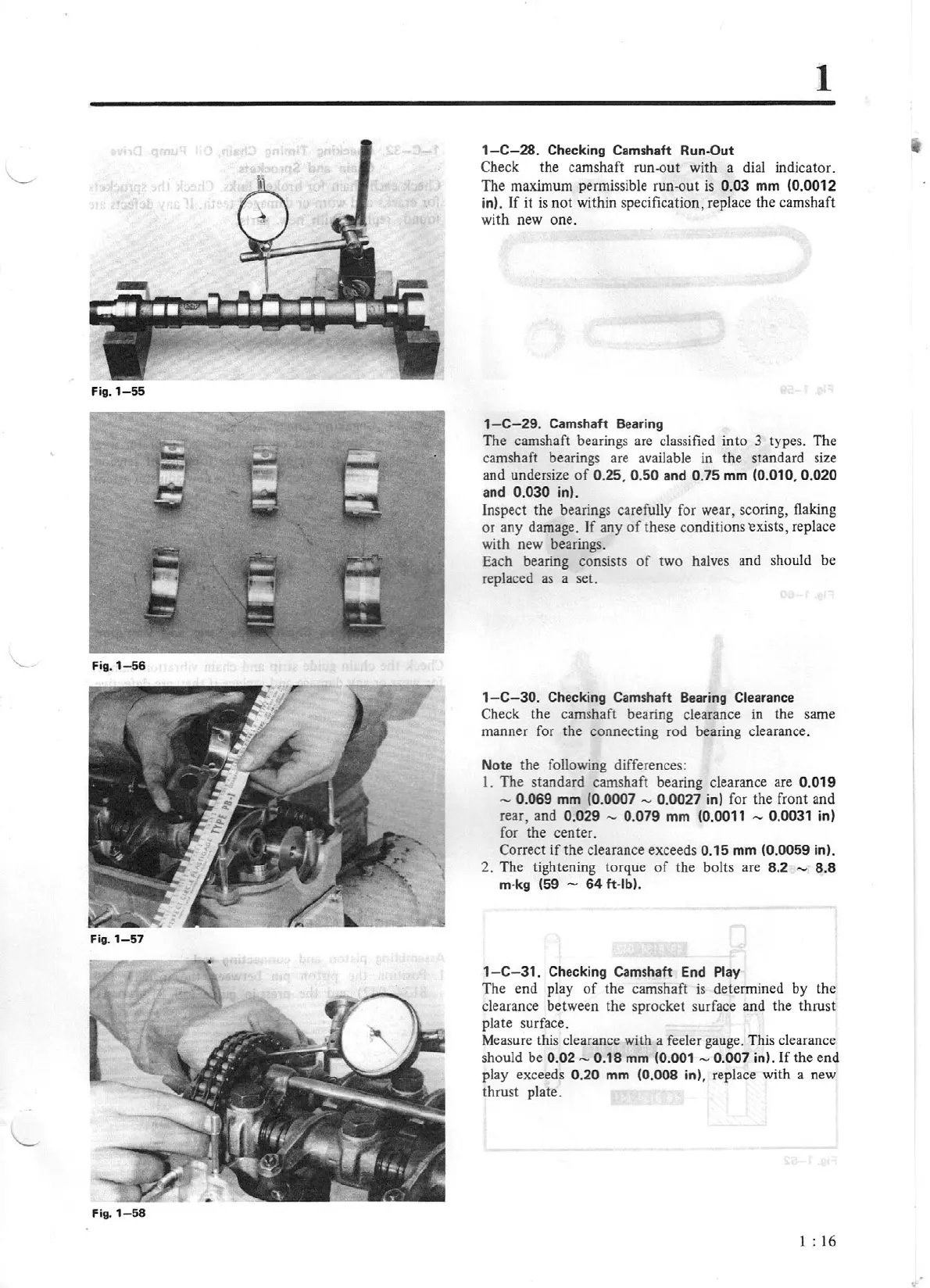

1-C-29

.

Camshaft

Bearing

The camshaft bearings are classified into 3 types. The

camshaft bearings are available in the standard size

and undersize

of

0.25, 0.50

and

0.75

mm

(0.010, 0.020

and

0.030 in).

Inspect the bearings carefully for wear, scoring, flaking

or

any damage.

If

any

of

these conditions -exists, replace

with new bearings.

Each bearing consists

of

two halves and should be

replaced

as

a set.

1-C-30

.

Checking

Camshaft

Bearing

Clearance

Check the camshaft bearing clearance in the same

manner for

the

connecting rod bearing clearance.

Note

the

following differences:

1. The standard camshaft bearing clearance are

0.019

- 0.069

mm

(0.0007 - 0.0027 in) for the front and

rear, and

0.029 - 0.079

mm

(0.0011 - 0.0031 in)

for the center.

Correct

if

the

clearance exceeds 0.15

mm

(0.0059 in).

2. The tightening torque

of

the

bolts are 8.2 -

8.8

m-

kg

(59 -

64

ft

-lb).

1-C-31.

Checking

Camshaft

End

Play

The end play

of

the camshaft

is

determined by the

clearance between the sprocket surface and the thrust

plate surface.

Measure this clearance with a feeler gauge. This clearance

should be

0.

02

- 0.18

mm

(0.001 - 0.007 in).

If

the

end

play exceeds 0.

20

mm

(0.008 in), replace with a new

thrust plate.

1 : 16

Loading...

Loading...