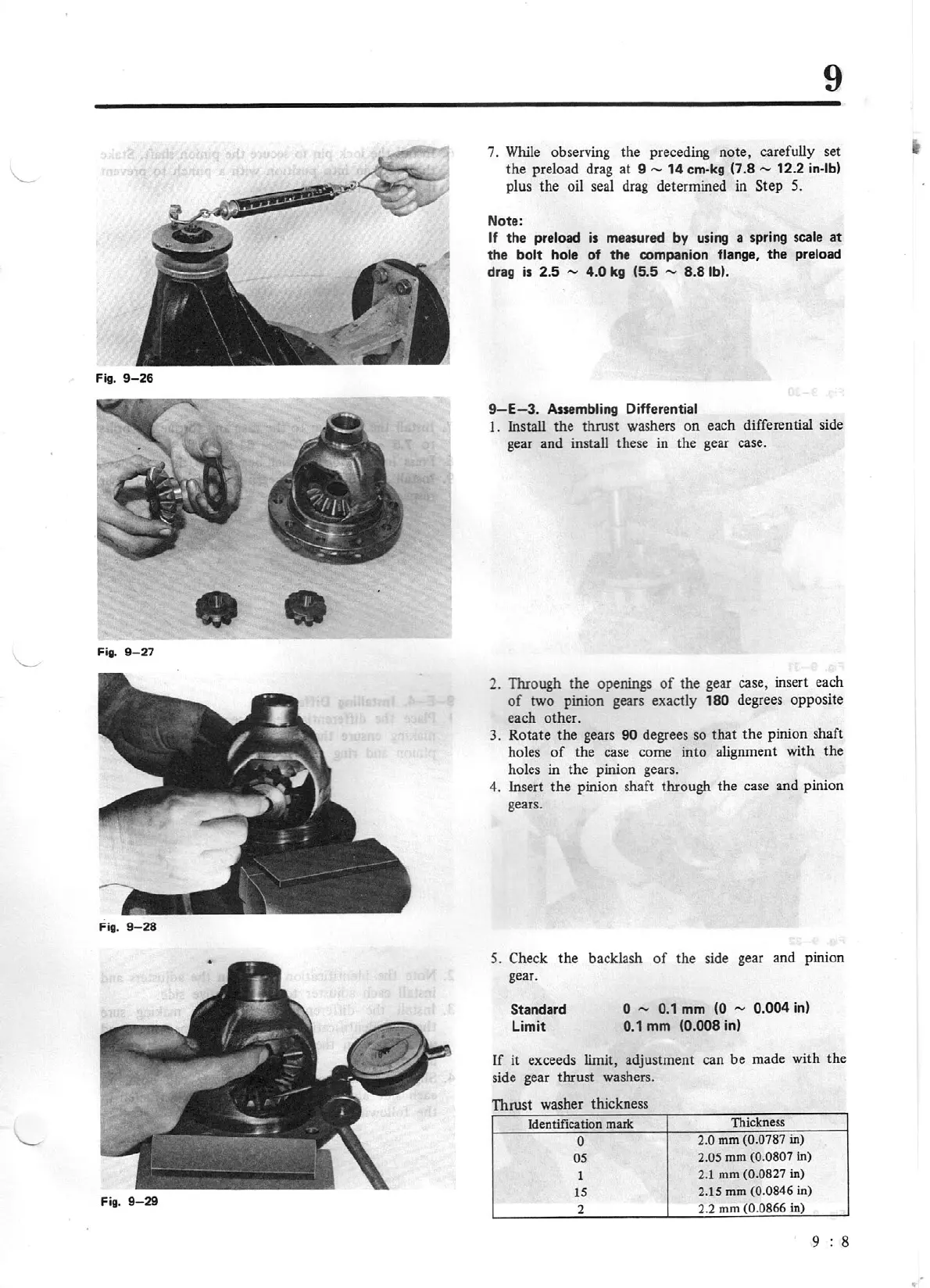

Fig.

9-26

•

•

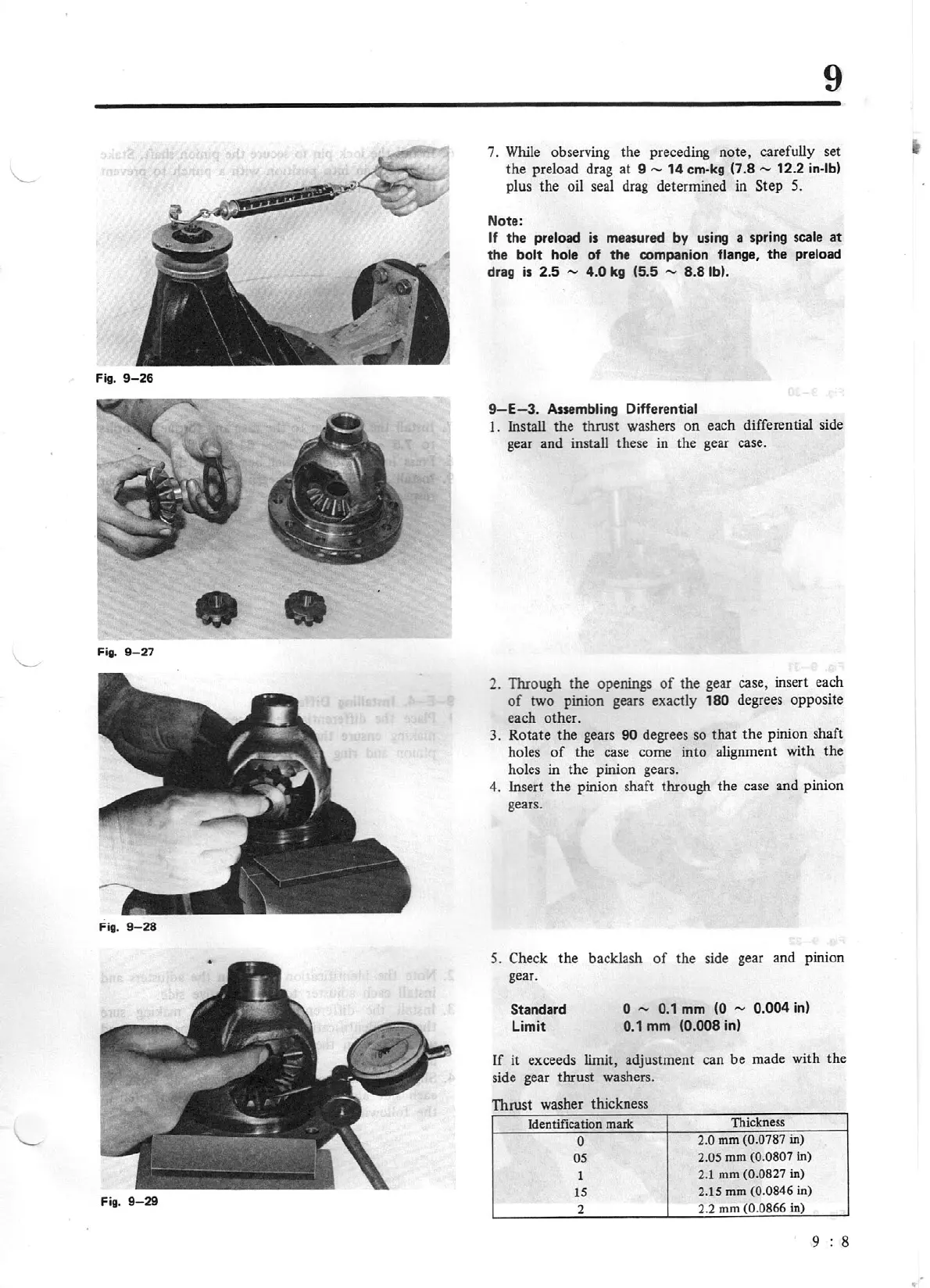

Fig.

9-27

Fig.

9-28

Fig.

9-29

9

7.

While

observing the preceding note, carefully set

the preload drag at 9 -

14

cm-kg

(7

.8

-

12.2

in·lb)

plus the oil seal drag determined in Step 5.

Note:

If

the

preload

is

measured

by

using a spring scale

at

the

bolt

hole

of

the

companion

flange,

the

preload

drag

is

2.5

- 4.0 kg (5.5

....

8.8

lb).

9-E-3

.

Assembling Differential

1.

Install the thrust washers on each differential side

gear and install these in the gear case .

2.

Through the openings

of

the gear case, insert each

of

two pinion gears exactly 180 degrees opposite

each other.

3. Rotate the gears

90

degrees so that the pinion shaft

holes

of

the case come into alignme

nt

with the

holes in the pinion gears.

4. Insert the pinion shaft through the case and pinion

gears.

5. Check the backlash

of

the side gear and pinion

gear.

Standard

Limit

0 - 0.1

mm

(0 - 0.004

in)

0.1

mm

(0.008

in)

If

it exceeds limit, adjustment can be made with the

side gear thrust washers.

Thrust washer thickness

Identification mark

Thickness

0

2.0 mm

(0.0787

in)

05

2.05

mm

(0.0807

in)

1

2.1 mm

(0

.0827

in)

15

2.15 mm

(0.0846

in)

2

2.2 mm (0.0866

in)

9 8

Loading...

Loading...