Fig.

lA-66

Fig.

lA-67

. Fig.

1A-69

Vac

ULJ!ll

amplifier

1A

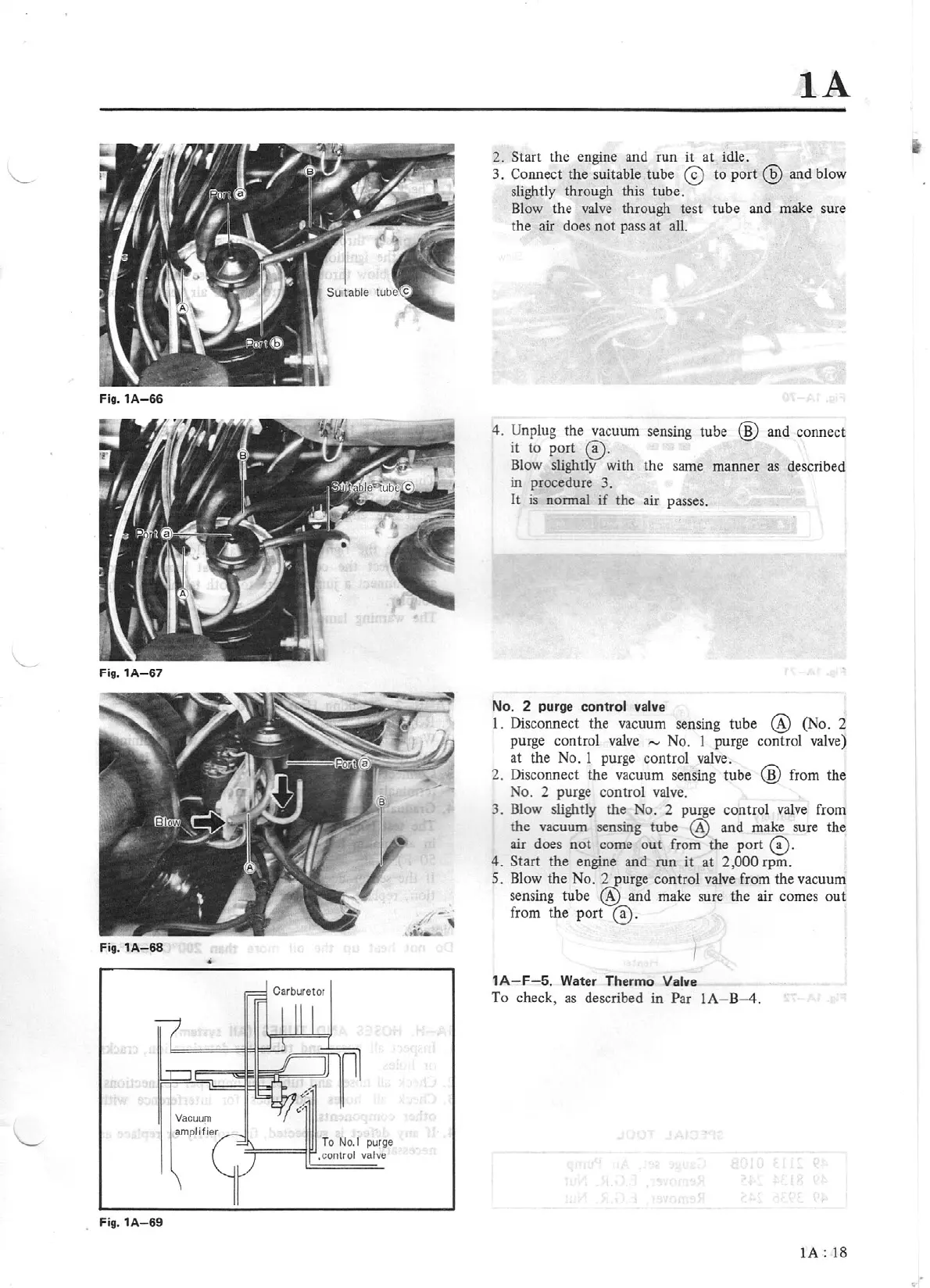

2.

Start the engine and run it at idle.

3. Connect the suitable tube ©

to

port @ and blow

slightly through this tube.

Blow the

valve

through test tube and make sure

the air does not pass at all.

4.

Unplug the vacuum sensing tube @ and connect

it

to port ©·

Blow slightly with the same manner

as

described

in procedure 3.

It

is

normal

if

the air passes.

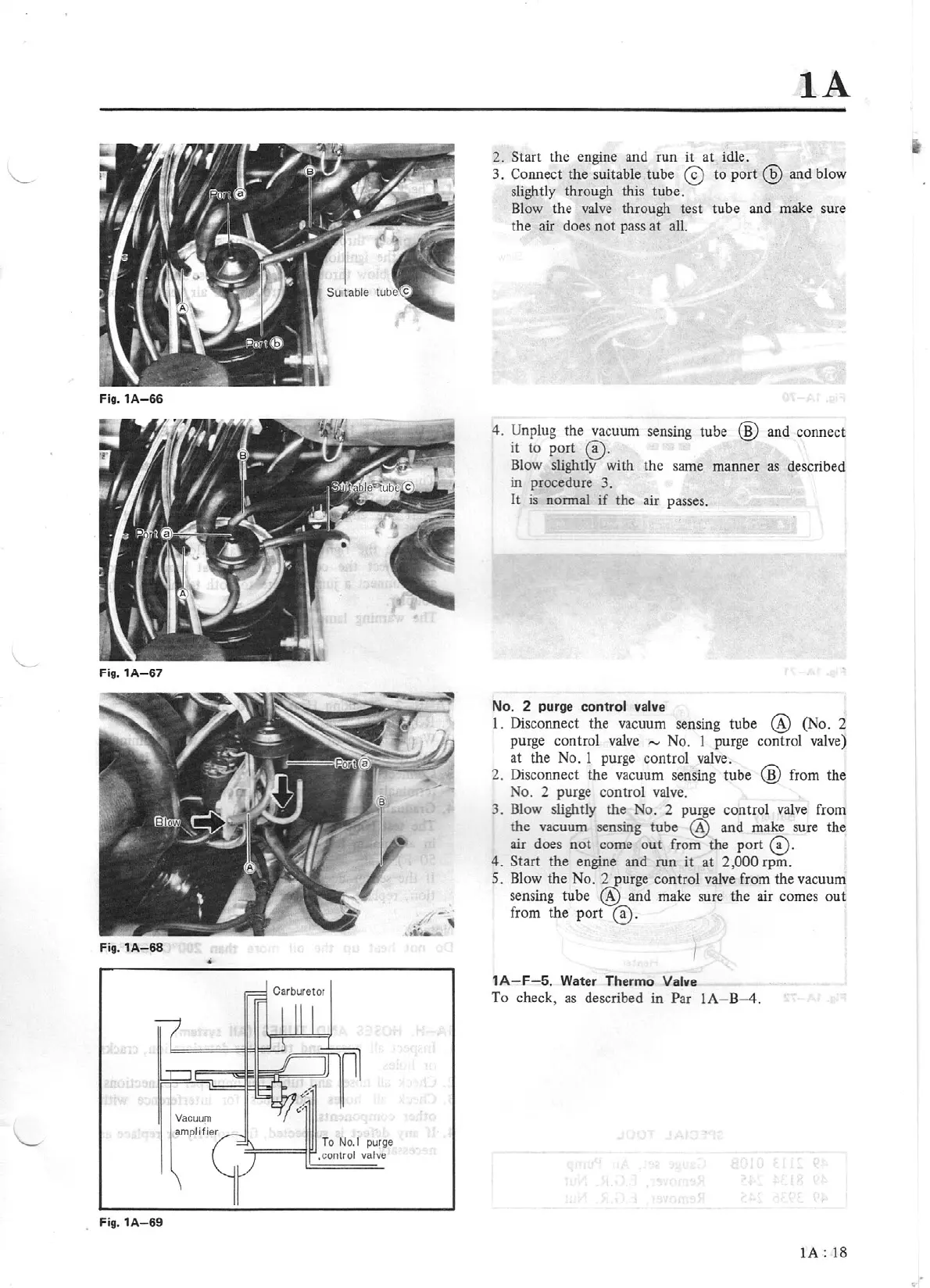

No. 2

purge

control valve

1. Disconnect the vacuum sensing tube @ (No. 2

purge control

valve

,.._,

No. 1 purge control valve)

at the No. 1 purge control valve.

2. Disconnect the vacuum sensing tube

@ from the

No. 2 purge control valve.

3. Blow slightly the No. 2 purge control valve from

the vacuum sensing tube @ and make sure the

air does

not

come

out

from the

port®·

4.

Start the engine and run

it

at 2,000 rpm.

S.

Blow the No. 2 purge control valve from the vacuum

sensing tube

@ and make sure the air comes out

from the port ©.

1A-

F

-5.

Water

Thermo Valve

To

check,

as

described in Par

lA-B-4

.

lA:

18

Loading...

Loading...