9

Fig.

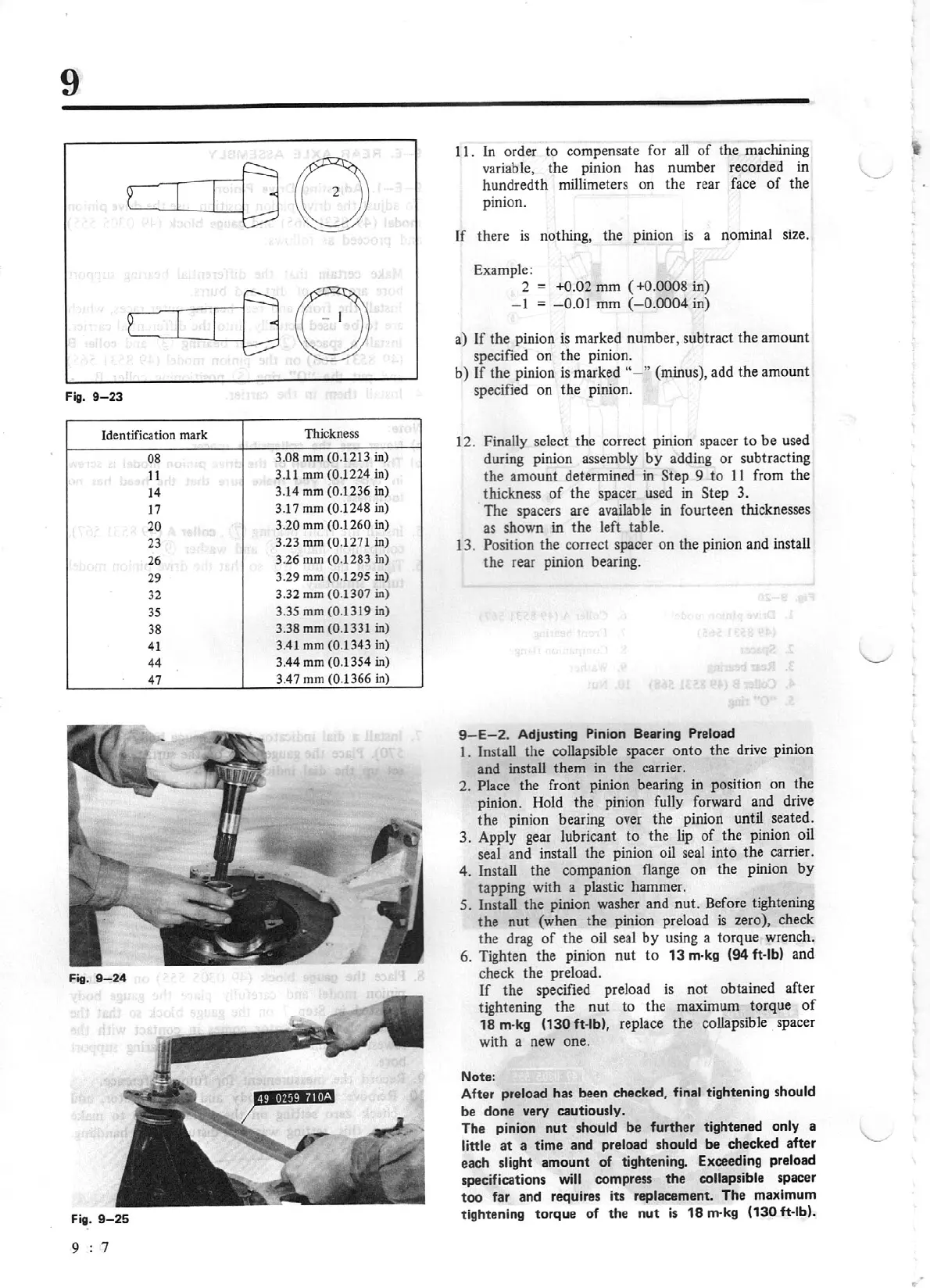

9-23

Identification mark

Thickness

08

3.08

mm

(0.1213

in)

11

3.11

mm

(0.1224

in)

14

3.14 mm (0.1236

in)

17

3.17 mm

(0.12

48

in)

20

3.20

mm

(0.J 260

in)

23 3.23 mm (0.

12

71

in)

26 3.26 mm (0.1283

in)

29 3.29

mm

(0.1295

in)

32 3.32

mm

(0.1307

in)

35

3.

35

mm

(0.1319

in)

38 3.38 mm

(0.1331

in)

41

3.41 mm

(0.13

43

in)

44

3.

44

mm

(0.1354

in

)

47

3.

47

mm

(0

.1366

in)

Fig.

9-26

9 : 7

1

1.

In order to compensate

fo

r all

of

the machining

variable, the pinion has number recorded in

hundredth millimeters on the rear face

of

the

pinion.

If

there

is

nothing,

th

e pinion

is

a nominal size.

Example:

2 +0.02

mm

(

+0.0008

in)

- I

=

-

0.01

mm

(

-0.

0004

in)

a)

If

the pinion

is

marked number, subtract the amount

specified on the pinion.

b) If the pinion

is

marked "- "

(minus), add the amount

specified on the pinion.

12. Finally select the correct pinion spacer to

be

used

during pinion assembly

by

adding or subtracting

the amount determined in Step 9

to

11

from the

thickness

of

the spacer used in Step 3.

The spacers are available in fourteen thicknesses

as shown in the left table.

13. Position the correct spacer on the pinion and insta

ll

the rear pinion bearing.

9-

E-2

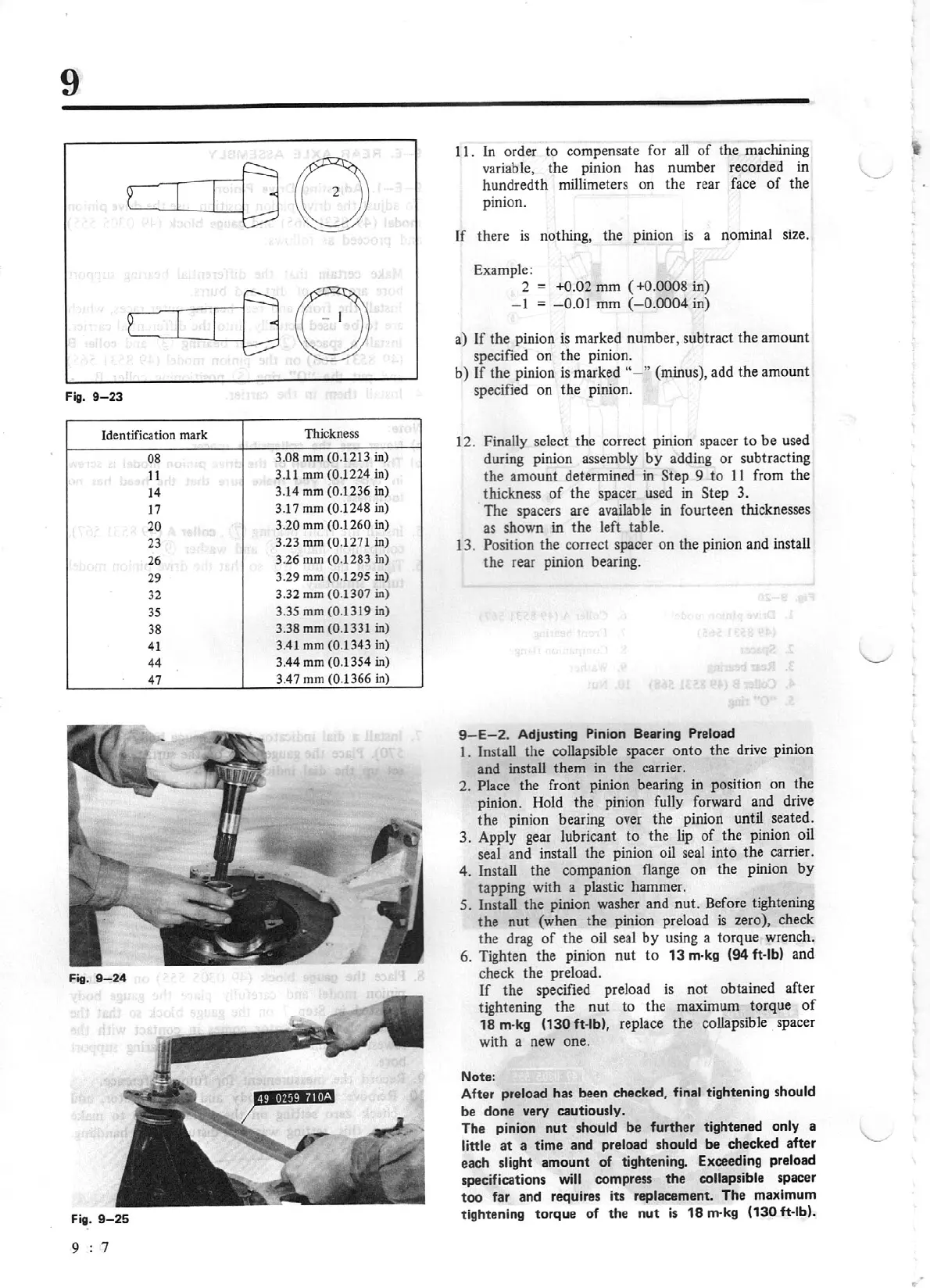

. Adjusting Pinion Bearing Preload

I.

Install the collapsible spacer

onto

the drive pinion

and install them in the carrier.

2.

Place

the front pinion bearing in position on the

pinion. Hold the pinion fully forward and drive

the

pinion bearing over the pinion until seated.

3. Apply gear lubricant

to

the lip

of

the pinion oil

seal and install the pinion oil seal into the carrier.

4. Install the companion flange on t

he

pinion

by

tapping with a plastic hammer.

5. Install the pinion washer a

nd

nut

. Before tightening

the

nut

(when the pinion preload

is

zero), check

the drag

of

the oil seal

by

using a

to

rque wrench.

6. Tighten the pinion

nut

to

13

m-kg

(94

ft-lb) and

check the preload.

If

the specified preload

is

not

obt

ained after

tightening the nut

to

the maximum torque

of

18

m-kg

(130

ft

-lb),

replace

the

collapsible spacer

with a new one.

Note:

After preload has been checked,

final

tightening should

be done very cautiously.

The pinion

nu

t should

be

further tightened

only

a

little

at a time

and

preload

should

be

checked after

each

slig

ht

amount

of

tighteni

ng.

Exceeding preload

specifications

will

compress

the

collapsible

spacer

too

far and requires

its

replacement. The maximum

tightening torque

of

the nut

is

18

m-kg

(130

ft-lb).

Loading...

Loading...