5

Fig.

5-14

Fig.

5-15

Fig.

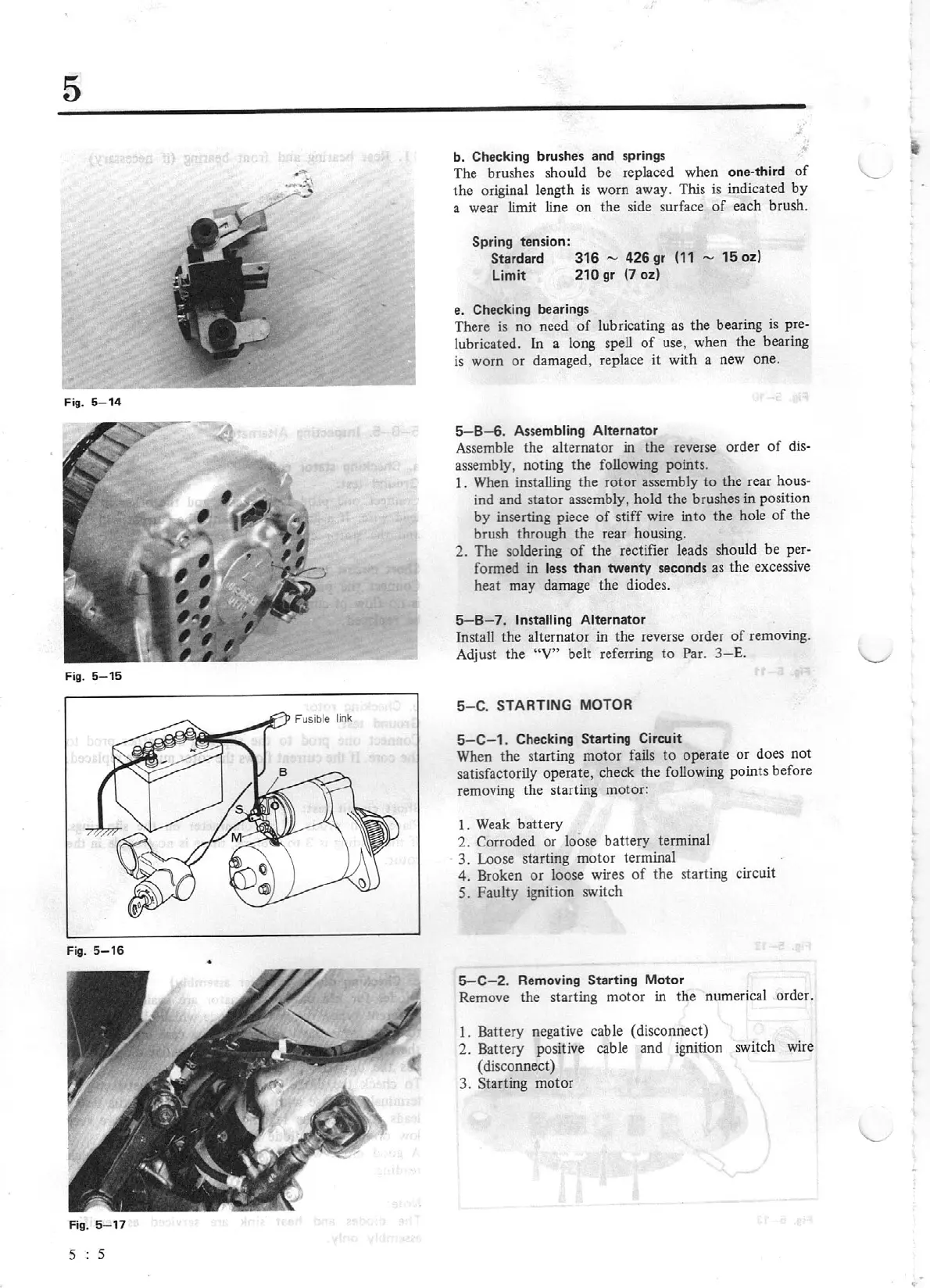

5-16

•

Fig. 5-

17

s : s

b. Checking

brushes and springs

The brushes should be replaced when one-third

of

the original length

is

worn away. This

is

indicated

by

a wear limit line on the side surface

of

each brush.

Spring

tension:

Stardard

316

- 426 gr

(11

- 15 oz)

Limit

210 gr (7 oz)

e.

Checking

bearings

There

is

no need

of

lubricating as the bearing

is

pre-

lubricated.

In

a long spell

of

use, when the bearing

is

worn

or

damaged, replace

it

with a new one.

5-B-6.

Assembling Alternator

Assemble the alternator in the reverse order

of

dis-

assembly, noting the following points.

I.

When

installing the rotor assembly to the rear hous-

ind and stator

assembly, hold the brushes in position

by inserting piece

of

stiff wire into the hole

of

the

brush through the rear housing.

2. The soldering

of

the rectifier leads should be

per-

formed in

less

than twenty seconds as the excessive

heat may damage the diodes.

5-B

- 7.

Installing Alternator

Install the alternator in the reverse order

of

removing.

Adjust the

"V"

belt referring

to

Par.

3-

E.

5-C

. STARTING

MOTOR

5-C-1

. Checking

Starting

Circuit

When the starting motor fails

to

operate

or

does not

satisfactorily operate, check the following points before

removing the starting motor:

I.

Weak

battery

2.

Corroded or loose battery terminal

3. Loose starting motor terminal

4. Broken

or

loose wires

of

the starting circuit

S. Faulty ignition switch

5-C-2.

Removing Starting Motor

Remove the starting motor in the numerical order.

I.

Battery negative cable (disconnect)

2. Battery positive cable and ignition switch wire

(disconnect)

3. Starting motor

Loading...

Loading...