- -

-

t

Pclir.1ii1

lire

~

-·

Fig.

4-51

Fig.

4-02

Flg. 4

-53

Fig. 4- 54

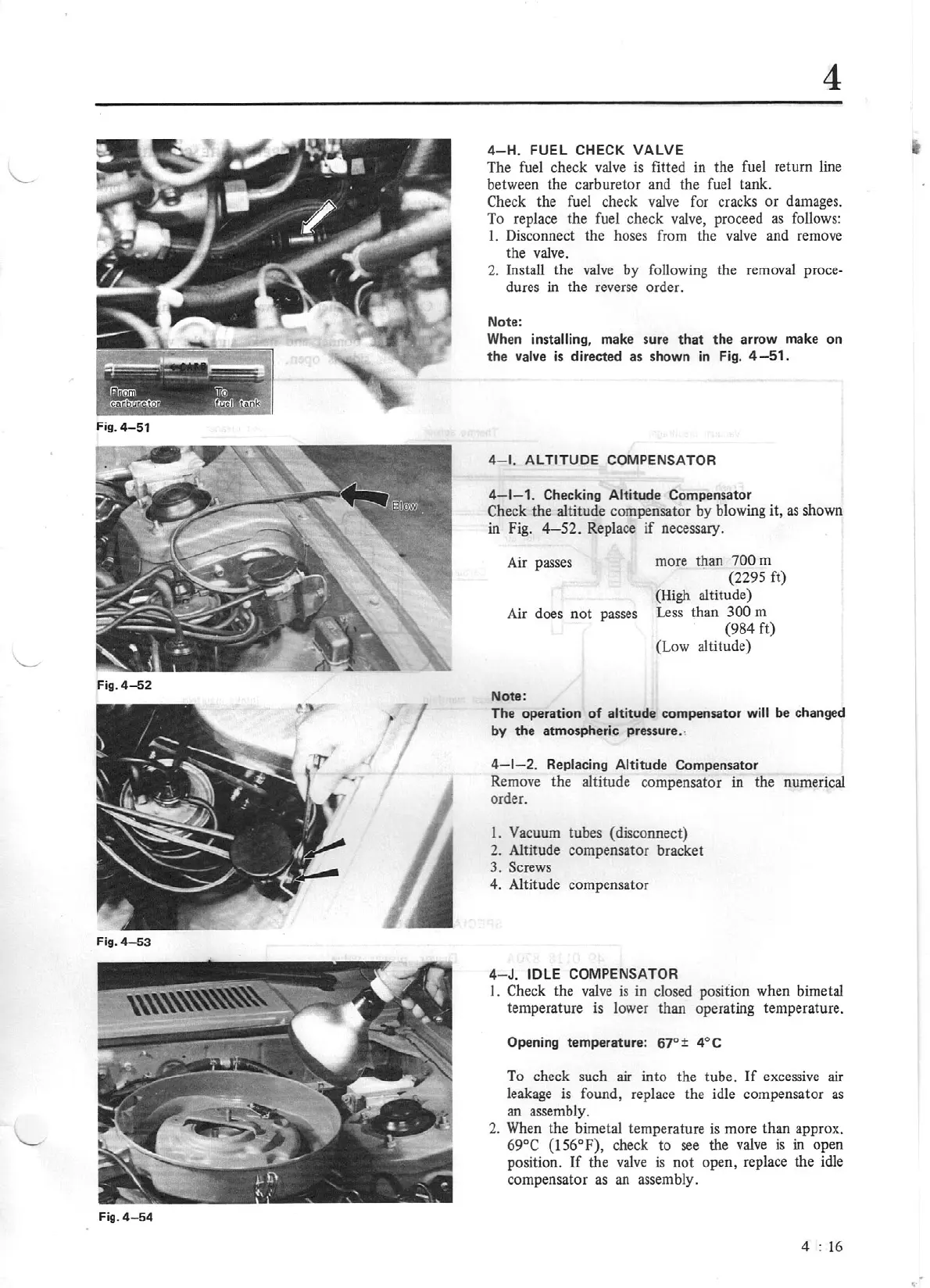

4

4-

H.

FU

EL

CHECK VALVE

The fuel check valve

is

fitted in the fuel return line

between the carburetor and the fuel tank.

Check

th

e fuel check valve for cracks or damages.

To replace

the

fuel check valve, proceed as follows:

l.

Disconnect the hoses from the valve and remove

the

valve.

2. Install

the

valve

by

following

the

removal proce-

dures in

the

reverse order.

Not

e:

Wh

en

installing, make sure

th

at

th

e arrow make

on

t he

v

al

ve

is

directed as shown in

Fig

. 4 - 51.

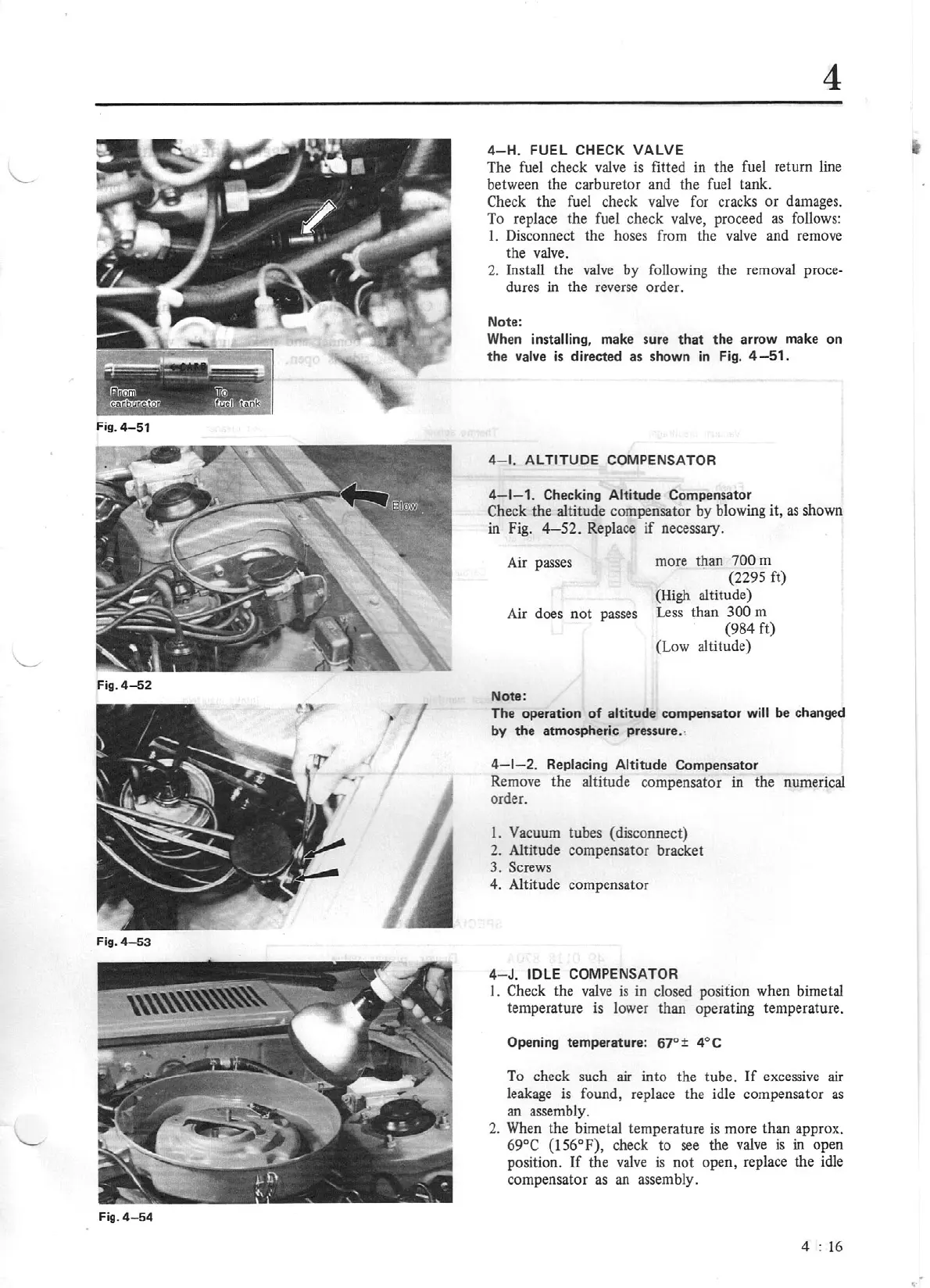

4- 1. ALTITUDE COMPENSATOR

4- 1- 1.

Checking Altitude C

om

pensa

tor

Check the

al

titude

compensator by blowing

it,

as shown

in

Fig.

4-

52.

Replace

if

necessary.

Air passes

Air does

not

passes

No

te:

more than

7

00

m

(

22

95 ft)

(High altitude)

Less than

300

m

(984

ft)

(L

ow altitude)

The operation

of

altitude compensator

will be chan

ge

d

by the

at

mospheric pressure.-

4-

1- 2.

Replacing Altitude Compensator

Remove

the

altitude compensator

in

the numerical

order.

1.

Vacuum

tubes (disconnect)

2. Altitude compensator bracket

3.

Screws

4. Altitude compensator

4- J.

IDLE

COMPEN

SATOR

I.

Check the valve

is

in closed position when bimetal

temperature is lower than operating temperature.

Opening temper

at

ure:

67

°±

4°C

To check such air into the tube.

If

excessive air

leakage is found, replace the idle compensator

as

an assembly.

2. When the bi

meta

l temperature is more than approx.

69°C (156

°F

),

check to

see

the

valve

is

in

open

pos

it ion.

If

the val

ve

is

not

open, replace the idle

compensa

tor

as an assembl

y.

4 :

16

Loading...

Loading...