Speed control under Real sensorless vector control, vector control, PM sensorless vector

control

192

PARAMETERS

5.3.5 Performing high-accuracy, fast-response control

(gain adjustment for Real sensorless vector

control, vector control and PM sensorless

vector control)

The value for the FR-A820-03160(55K) or lower and FR-A840-01800(55K) or lower.

The value for the FR-A820-03800(75K) or higher and FR-A840-02160(75K) or higher.

The load inertia ratio (load moment of inertia) for the motor is calculated in real time from the torque command and

rotation speed during motor driving by the vector control. Because the optimum gain for speed control and position

control is set automatically from the load inertia ratio and the response level, the work required for gain adjustment is

reduced. (Easy gain tuning)

If the load inertia ratio cannot be calculated due to load fluctuations, or under Real sensorless vector control or PM

sensorless vector control, the control gain can be set automatically by entering the load inertia ratio manually.

Manual gain adjustment is useful for achieving optimum machine performance or improving unfavorable conditions,

such as vibration and acoustic noise during operation with high load inertia or gear backlash.

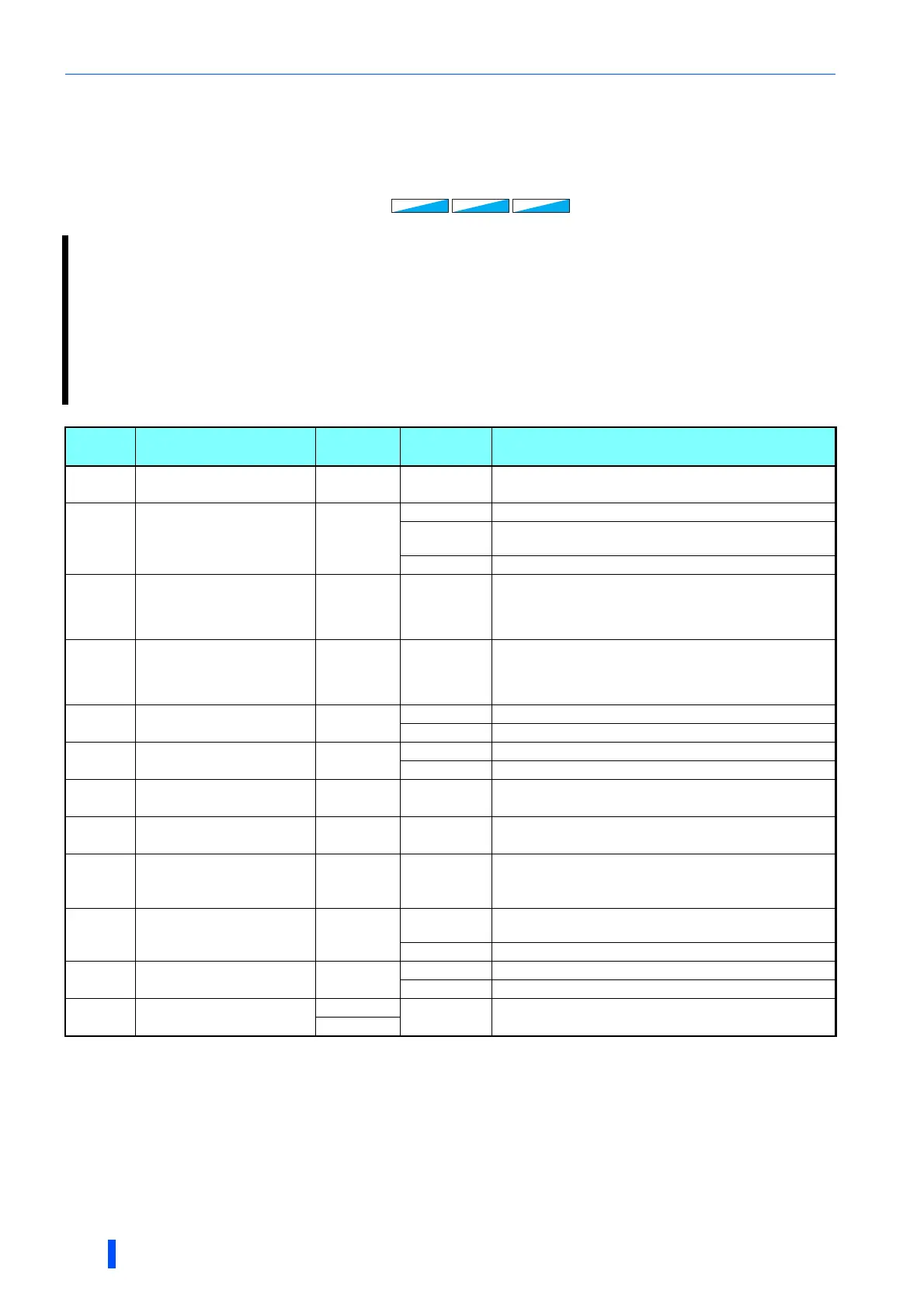

Pr. Name

Initial

value

Setting

range

Description

818

C112

Easy gain tuning

response level setting

2 1 to 15

Set the response level.

1 (slow-response) to 15 (fast-response)

819

C113

Easy gain tuning

selection

0

0 No easy gain tuning

1

Gain is calculated with load calculation

(This function is valid under vector control.)

2 Gain is calculated with load (Pr.880) manual input

820

G211

Speed control P gain 1

60% 0 to 1000%

The proportional gain during speed control is set. (Setting

this parameter higher improves the trackability for speed

command changes. It also reduces the speed fluctuation

caused by external disturbance.)

821

G212

Speed control integral

time 1

0.333 s 0 to 20 s

The integral time during speed control is set. (Setting this

parameter lower shortens the return time to the original

speed when the speed fluctuates due to external

disturbance.)

830

G311

Speed control P gain 2

9999

0 to 1000% Second function of Pr.820 (valid when RT signal is ON)

9999 The Pr.820 setting is applied to the operation.

831

G312

Speed control integral

time 2

9999

0 to 20 s Second function of Pr.821 (valid when RT signal is ON)

9999 The Pr.821 setting is applied to the operation.

880

C114

Load inertia ratio

7-fold 0 to 200-fold Set the load inertia ratio for the motor.

1115

G218

Speed control integral

term clear time

0 ms 0 to 9998 ms

Set time until the integral term is reduced and cleared after P

control switching.

1116

G206

Constant output range

speed control P gain

compensation

0% 0 to 100%

Set a compensation amount of the speed control P gain in

the constant output range (rated speed or higher).

1117

G261

Speed control P gain 1

(per-unit system)

9999

0 to 300

Set a proportional gain under speed control in the per-unit

system.

9999 The Pr.820 setting is applied to the operation.

1118

G361

Speed control P gain 2

(per-unit system)

9999

0 to 300 Second function of Pr.1117 (valid when RT signal ON)

9999 The Pr.1117 setting is applied to the operation.

1121

G260

Per-unit speed control

reference frequency

120 Hz

0 to 400 Hz

Set the speed at 100% when setting speed control P gain or

model speed control gain in the per-unit system.

60 Hz

Sensorless

Sensorless

Vector

Vector

PM

PM

Loading...

Loading...