Torque control under Real sensorless vector control and vector control

PARAMETERS

225

5

Speed limit mode switching by external terminals (Pr.1113="10")

• The speed limit mode can be switch between 3 and 4 using the torque control selection (X93) signal.

• To assign the X93 signal, set "93" in any of Pr.178 to Pr.189 (input terminal function selection).

NOTE

• During the speed limit operation, (SL) is displayed on the operation panel and OL signal is output.

• OL signal is assigned to the terminal OL in the initial status. Set "3" in any of Pr.190 to Pr.196 (output terminal function

selection) to assign the OL signal to another terminal. Changing the terminal assignment using Pr.190 to Pr.196 may affect

the other functions. Set parameters after confirming the function of each terminal.

• Changing the terminal assignment using Pr.178 to Pr.189 (input terminal function selection) may affect the other

functions. Set parameters after confirming the function of each terminal.

Pr.1 Maximum frequency, Pr.2 Minimum frequency page 345

Pr.4 to Pr.6, Pr.24 to Pr.27, Pr.232 to Pr.239 (Multi-speed operation) page 328

Pr.7 Acceleration time, Pr.8 Deceleration time page 285

Pr.13 Starting frequency page 298

Pr.190 to Pr.196 (output terminal function selection) page 384

Pr.868 Terminal 1 function assignment page 410

Pr.125, Pr.126, C2 to C7, C12 to C15 (frequency setting voltage (current) bias gain) page 415

5.4.6 Torque control gain adjustment

Current loop proportional (P) gain adjustment (Pr.824)

• The 100% current loop proportional gain is equivalent to 1000 rad/s during Real sensorless vector control, and to 1400 rad/

s during vector control.

• For ordinary adjustment, try to set within the range of 50 to 500%.

• Set the proportional gain for during speed control.

• If setting value is large, changes in current command can be followed well and current fluctuation relative to external

disturbance is smaller. If the setting value is however too large, it becomes unstable and high frequency torque pulse is

produced.

Current control integral time adjustment (Pr.825)

• Set the integral time of current control during torque control.

• Torque response increases if set small; current however becomes unstable if set too small.

• If the setting value is small, it produces current fluctuation toward disturbance, decreasing time until it returns to original

current value.

X93 signal Speed limit mode

OFF Mode 3 (torque command=positive, Pr.1113=1 or equivalent)

ON Mode 4 (torque command=negative, Pr.1113=2 or equivalent)

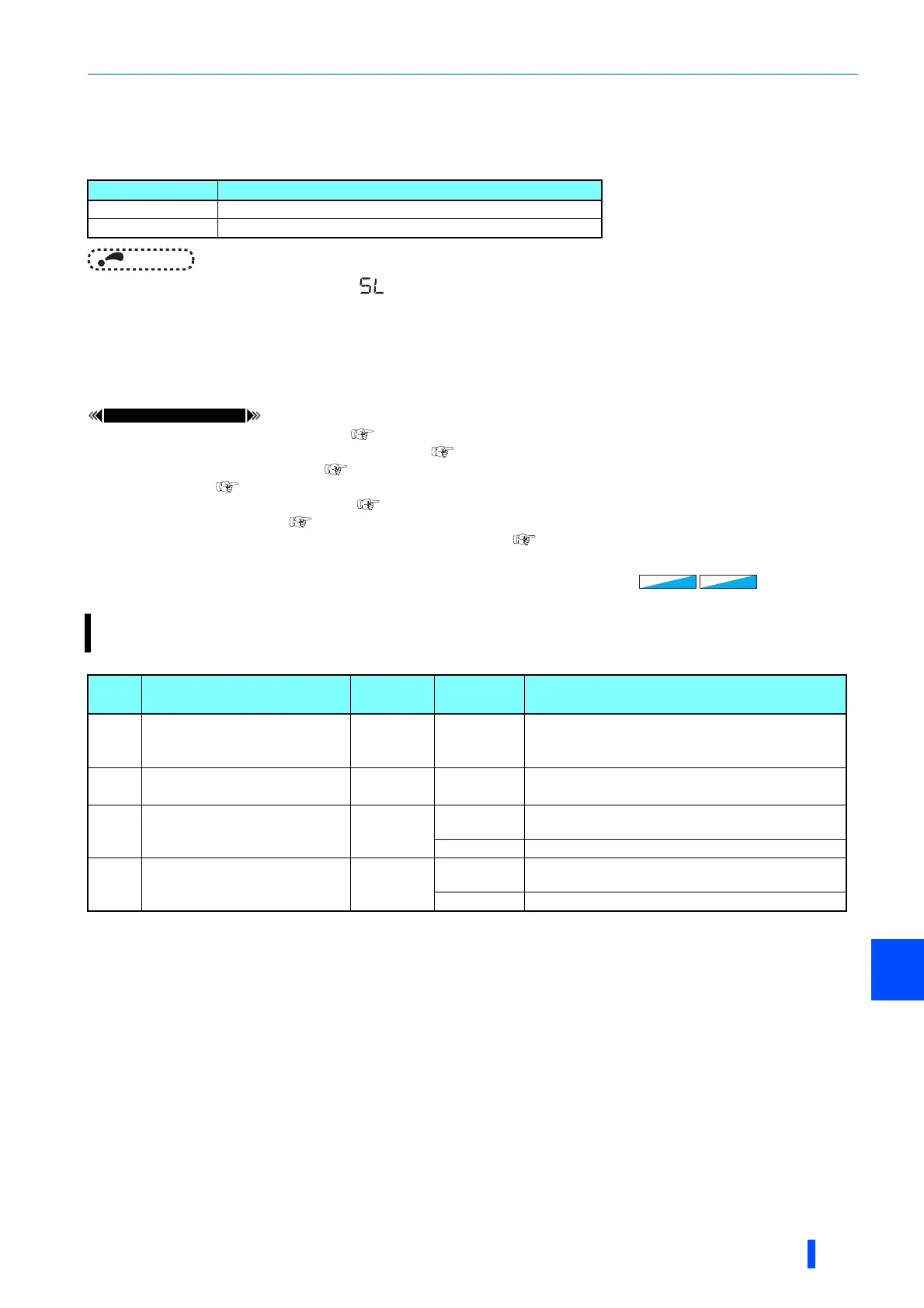

Operation is normally stable enough in the initial setting, but some adjustments can be made if if abnormal vibration,

noise or overcurrent occur for the motor or machinery.

Pr. Name

Initial

value

Setting

range

Description

824

G213

Torque control P gain 1

(current loop proportional

gain)

100% 0 to 500%

Sets the current loop proportional gain.

100% is the equivalent to 2000 rad/s.

825

G214

Torque control integral time 1

(current loop integral time)

5 ms 0 to 500 ms Sets current loop integral compensation time.

834

G313

Torque control P gain 2

9999

0 to 500%

Sets the current loop proportional gain when RT signal is

ON.

9999 The Pr.824 setting is applied to the operation.

835

G314

Torque control integral time 2

9999

0 to 500 ms

Sets the current loop integral compensation time when

RT signal is ON.

9999 The Pr.825 setting is applied to the operation.

Sensorless

SensorlessSensorless

SensorlessSensorless

Sensorless

Vector

Vector

Loading...

Loading...