Speed control under Real sensorless vector control, vector control, PM sensorless vector

control

PARAMETERS

195

5

Adjusting the speed control gain manually (Pr.819 = "0" No easy gain

tuning)

• The speed control gain can be adjusted for the conditions such as abnormal machine vibration, acoustic noise, slow

response, and overshoot.

• Pr.820 Speed control P gain 1="60% (initial value)" is equivalent to 120 rad/s (speed response of a single motor).

(Equivalent to the half the rad/s value during Real sensorless vector control or with the FR-A820-03800(75K) or higher and

FR-A840-02160(75K) or higher during vector control.) Setting this parameter higher speeds up the response, but setting

this too high causes vibration and acoustic noise.

• Setting Pr.821 Speed control integral time 1 lower shortens the return time to the original speed during speed fluctuation,

but setting it too low causes overshoot.

The value in parentheses is applicable during Real sensorless vector control or with the FR-A820-03800(75K) or higher and FR-A840-

02160(75K) or higher during vector control.

Performing PM parameter initialization changes the settings. (Refer to page 173.)

• Actual speed gain is calculated as below when load inertia is applied.

• Adjust in the following procedure:

1) Change the Pr.820 setting while checking the conditions.

2) If it cannot be adjusted well, change Pr.821 setting, and perform 1) again.

Actual speed gain = Speed gain of a single motor

JM JM: Motor inertia

JL: Load inertia converted as the motor axis inertia

JM + JL

No. Movement condition Adjustment method

1 Load inertia is high.

Set Pr.820 and Pr.821 higher.

Pr.820

If acceleration is slow, raise the setting by 10%s and then set the value to 0.8 to 0.9

the setting immediately before vibration/noise starts occurring.

Pr.821

If overshoots occur, raise the setting by double the setting and then set the value to 0.8

to 0.9 the setting where overshoots stop occurring.

2

Vibration or acoustic noise

are generated from

machines.

Set Pr.820 lower and Pr.821 higher.

Pr.820

Lower the setting by 10%s and then set the value to 0.8 to 0.9 the setting

immediately before vibration/noise starts occurring.

Pr.821

If overshoots occur, raise the setting by double the setting and then set the value to 0.8

to 0.9 the setting where overshoots stop occurring.

3 Response is slow.

Set Pr.820 higher.

Pr.820

If acceleration is slow, raise the setting by 5%s and then set the value to 0.8 to 0.9

the setting immediately before vibration/noise starts occurring.

4

Return time (response time)

is long.

Set Pr.821 lower.

Lower Pr.821 by half the current setting and then set the value to 0.8 to 0.9 the setting

immediately before overshoots or unstable movements stop occurring.

5

Overshoots or unstable

movements occur.

Set Pr.821 higher.

Raise Pr.821 by double the current setting and then set the value to 0.8 to 0.9 the setting

immediately before overshoots or unstable movements stop occurring.

Pr.820

Setting

100%

60%

(initial value

)

Proportional gain

200 (100)rad/s

120 (60)rad/s

∗1

∗1

∗2

Since increasing the proportional gain enhances the

response level and decreases the speed fluctuation.

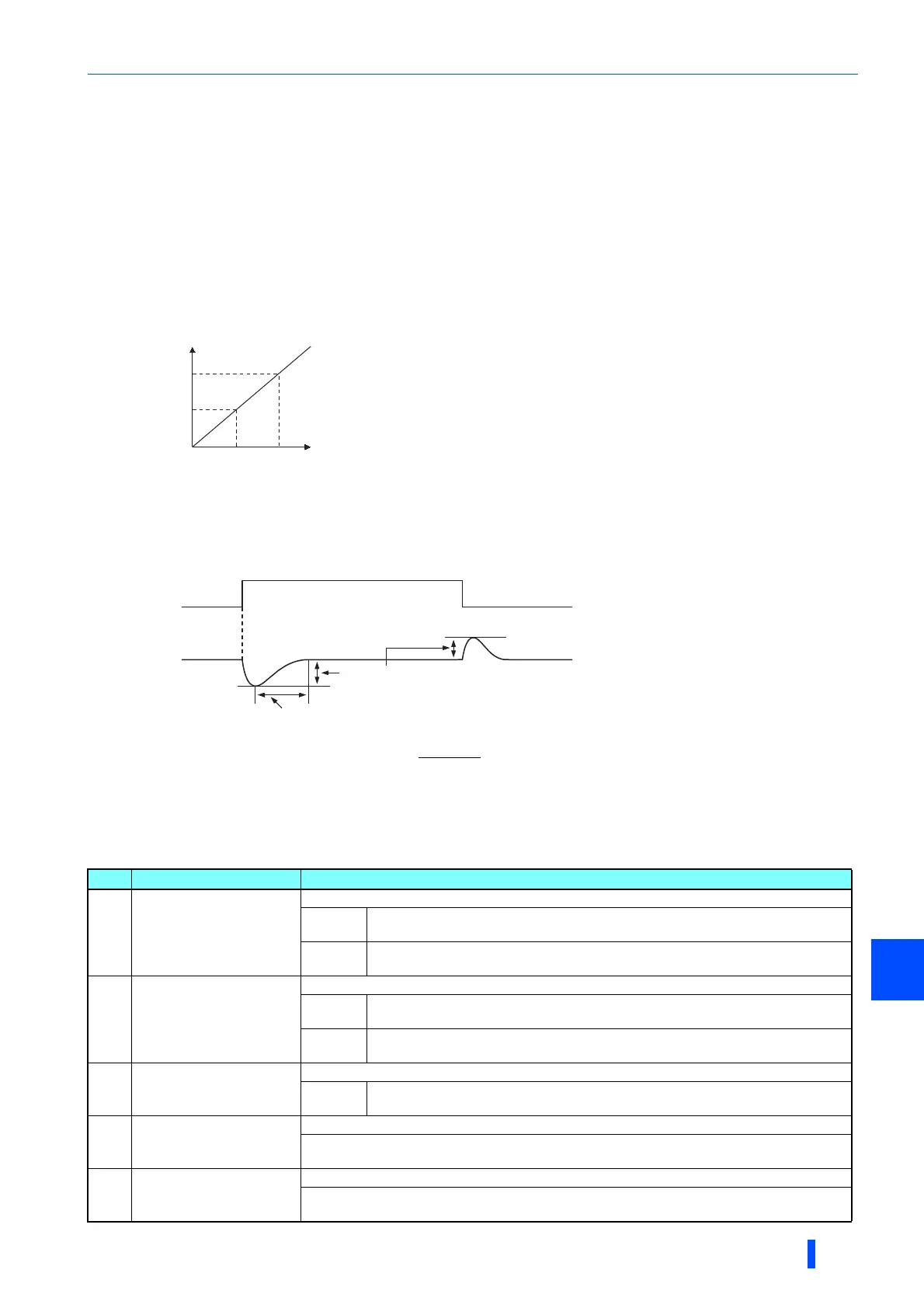

Load

fluctuation

Speed

Decreasing the integral time shortens the return time taken.

Loading...

Loading...