Measurement of main circuit voltages, currents and powers

684

PRECAUTIONS FOR MAINTENANCE AND INSPECTION

Measuring points and instruments

Use an FFT to measure the output voltage accurately. A tester or general measuring instrument cannot measure accurately.

When the carrier frequency exceeds 5 kHz, do not use this instrument since using it may increase eddy current losses produced in metal parts

inside the instrument, leading to burnout. In this case, use an approximate-effective value type.

When the setting of Pr.195 ABC1 terminal function selection is the positive logic

A digital power meter (designed for inverter) can also be used to measure.

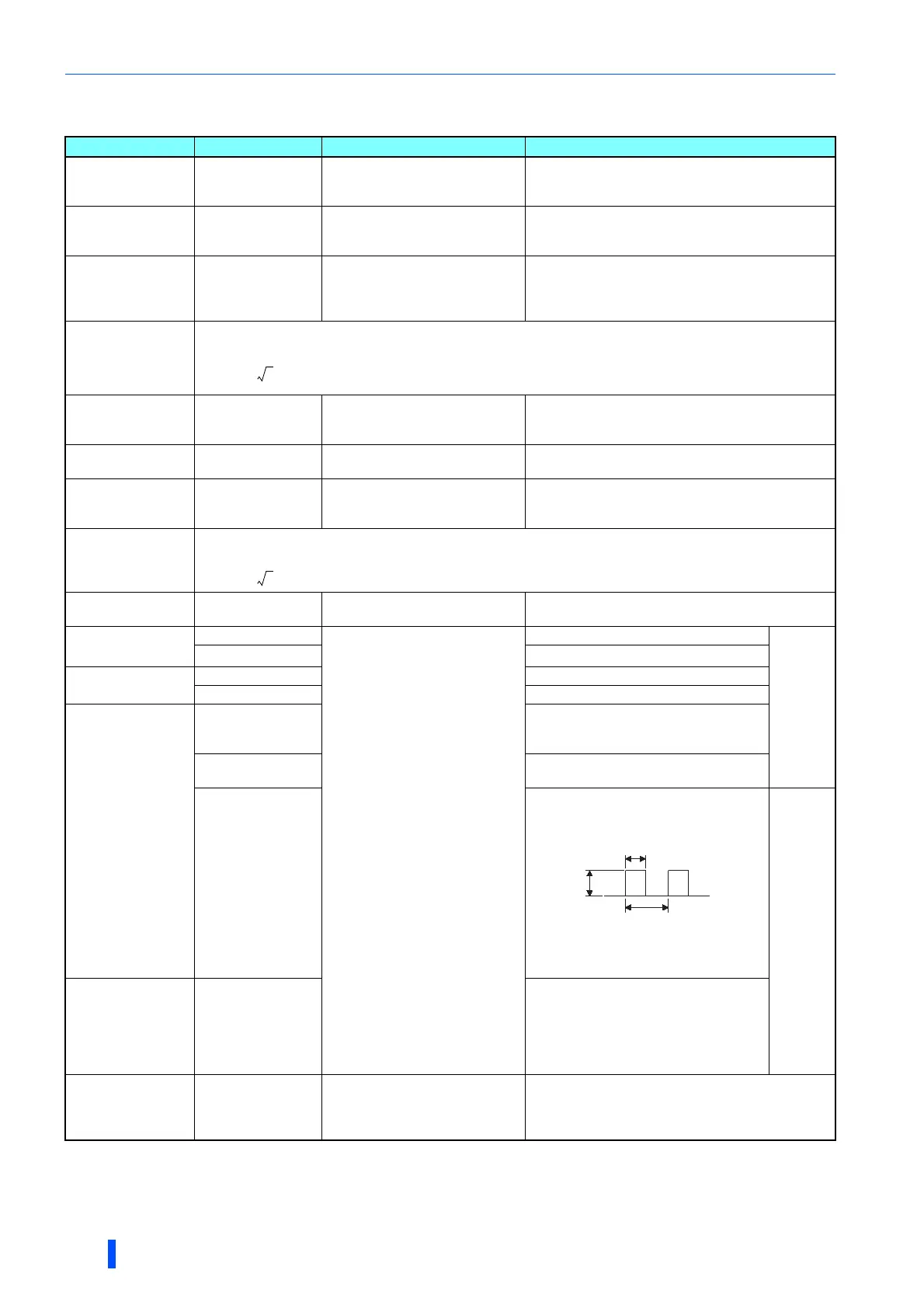

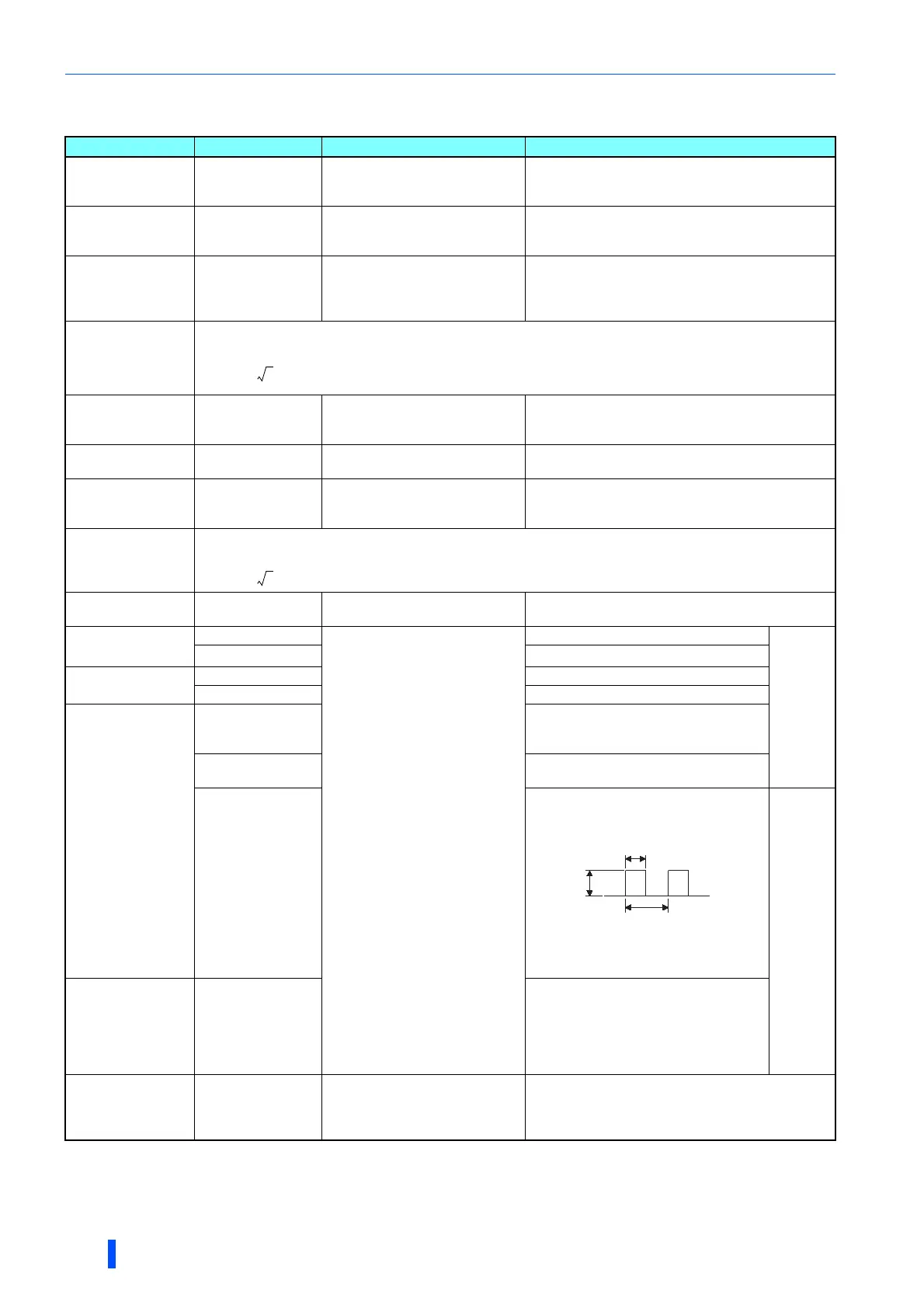

Item Measuring point Measuring instrument Remarks (reference measured value)

Power supply voltage

V1

Across R/L1 and S/L2,

S/L2 and T/L3,

T/L3 and R/L1

Moving-iron type AC voltmeter

Commercial power supply

Within permissible AC voltage fluctuation

(Refer to page 690.)

Power supply side

current

I

1

R/L1, S/L2, T/L3 line

current

Moving-iron type AC ammeter

Power supply side

power

P

1

R/L1, S/L2, T/L3 and

Across R/L1 and S/L2,

S/L2 and T/L3,

T/L3 and R/L1

Digital power meter (for inverter) or

electrodynamic type single-phase

wattmeter

P

1 = W11 + W12 + W13 (3-wattmeter method)

Power supply side

power factor

Pf

1

Calculate after measuring power supply voltage, power supply side current and power supply side power.

Output side voltage

V

2

Across U and V, V

and W, and W and U

Rectifier type AC voltage meter

(moving-iron type cannot

measure.)

Difference between the phases is within 1% of the

maximum output voltage.

Output side current

I

2

U, V and W line

currents

Moving-iron type AC ammeter

Difference between the phases is 10% or lower of the

rated inverter current.

Output side power

P

2

U, V, W and

across U and V, V

and W

Digital power meter (for inverter) or

electrodynamic type single-phase

wattmeter

P

2 = W21 + W22

2-wattmeter method (or 3-wattmeter method)

Output side power

factor

Pf

2

Calculate in similar manner to power supply side power factor.

Converter output Across P/+ and N/-

Moving-coil type

(such as tester)

Inverter LED is lit. 1.35 V

1

Frequency setting

signal

Across 2, 4(+) and 5

Moving-coil type

(tester and such may be used.)

(internal resistance 50 k or more)

0 to 10 VDC, 4 to 20 mA

"5" is .

common

Across 1(+) and 5

0 to ±5 VDC and 0 to ±10 VDC

Frequency setting

power supply

Across 10(+) and 5 5.2 VDC

Across 10E(+) and 5 10 VDC

Frequency meter

signal

Across AM(+) and 5

Approximately 10 VDC at maximum

frequency

(without frequency meter)

Across CA(+) and 5

Approximately 20 mADC at maximum

frequency

Across FM(+) and

SD

Approximately 5 VDC at maximum

frequency

(without frequency meter)

Pulse width T1:

Adjust with

C0 (Pr.900)

.

Pulse cycle T2: Set with Pr.55.

(frequency monitor only)

"SD" is

common

Start signal

Select signal

Reset signal

Output stop signal

Across STF, STR,

RH, RM, RL, JOG,

RT, AU,

STP (STOP)

,

CS, RES, MRS(+)

and SD (for sink

logic)

When open

20 to 30 VDC

ON voltage: 1 V or less

Fault signal

Across A1 and C1

Across B1 and C1

Moving-coil type

(such as tester)

Continuity check

[Normal] [Fault]

Across A1 and C1 Discontinuity Continuity

Across B1 and C1 Continuity Discontinuity

Pf1

P1

3V1 I 1

------------------------

100=

%

Pf2

P2

3V2 I2

------------------------

100=

%

8VDC

T1

T2

Loading...

Loading...