(A) Application parameters

PARAMETERS

523

5

GROUP

A

NOTE

• Normally, set Pr.7 Acceleration time and Pr.8 Deceleration time to "0 s". When the Pr.7 and Pr.8 settings are large, dancer

control response becomes slow during acceleration/deceleration.

• The Pr.127 PID control automatic switchover frequency setting is enabled. The larger setting value between Pr.7 and

Pr.44 is used as the acceleration time during normal operation. For the deceleration time, the larger setting value between

Pr.8 and Pr.45 is used. (For the details of Pr.127, refer to page 501.)

• If an automatic restart after instantaneous power failure is activated during dancer control, E.OC[] or E.OV[] is likely to occur.

In such case, disable the automatic restart after instantaneous power failure function (Pr.57 = "9999").

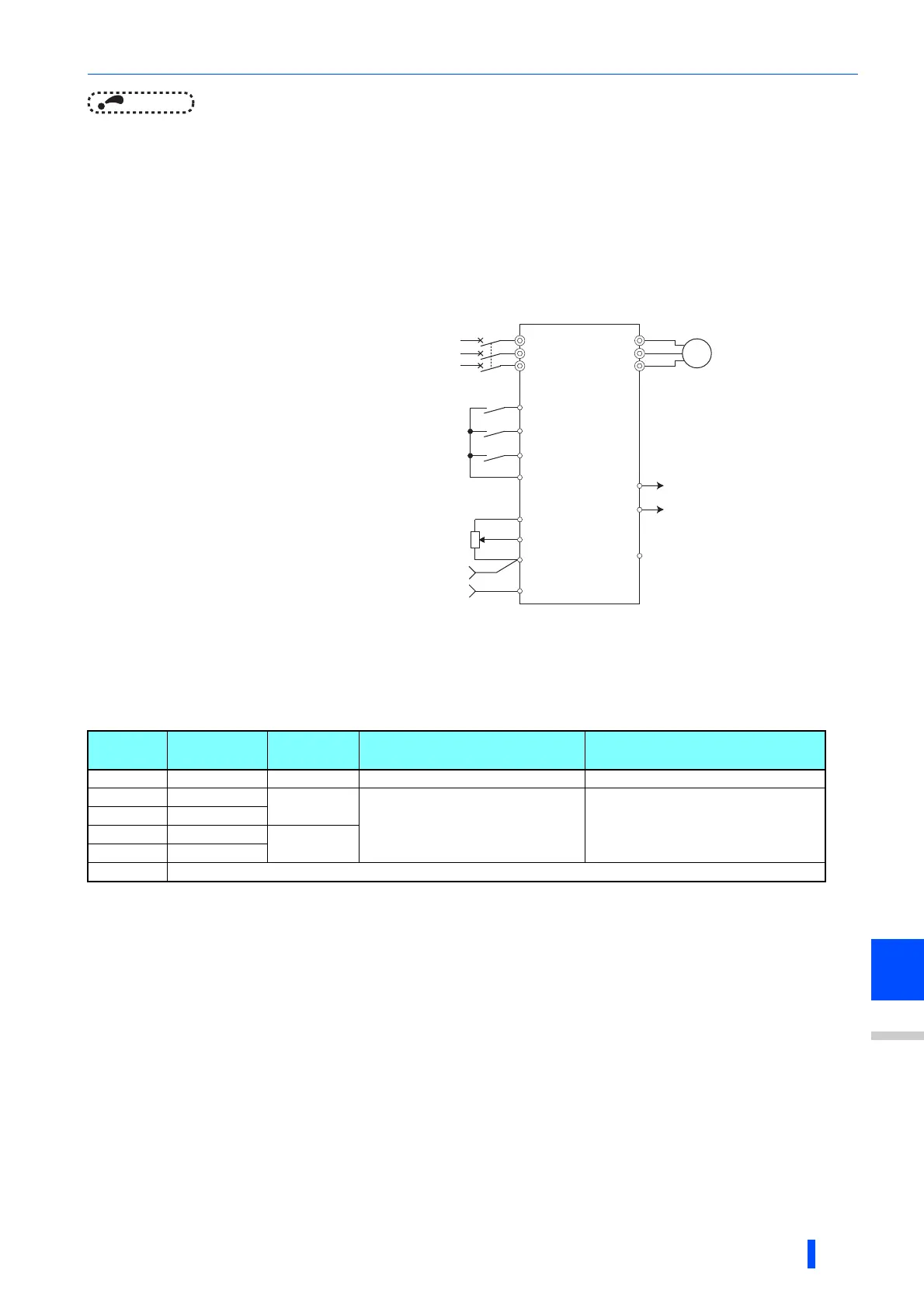

Connection diagram

Dancer control operation selection (Pr.128)

When Pr.133 "9999", the Pr.133 setting is valid.

• To enable dancer control, set "40 to 43" in Pr.128 PID action selection.

• Dancer control is enabled only when the PID control valid terminal (X14) signal turns ON when "14" is set in one of Pr.178

to Pr.182 (Input terminal function selection) and X14 signal is assigned.

When the X14 signal is not assigned, dancer control is enabled only by the Pr.128 setting.

• Input the main speed command (External, PU, Communication). Dancer control is also supported by the main speed

command in all operation modes.

• Input the set point between the terminals 2 and 5 (the setting can be selected using Pr.133 or Pr.609) and input the

measured value signal (dancer roll position detection signal) between the inverter terminals 4 and 5 (the setting can be

selected using Pr.610).

• The action of Pr.129 PID action selection, Pr.130 PID integral time, Pr.131 PID upper limit, Pr.132 PID lower limit and

Pr.134 PID differential time is the same as PID control action. In the relationship between the control amount (%) and

frequency in PID control, 0% and 100% are equivalent to the frequencies set to Pr.902 and Pr.903, respectively.

• Sink logic

• Pr.128 =41

• Pr.182 =14

• Pr.193 =14

• Pr.194 =15

• Pr.133 =set point

The main speed command differs according to each operation mode (External, PU, communication).

The output signal terminal to be used differs according to the Pr.190 to Pr.196 (Output terminal function selection) setting.

The input signal terminal to be used differs according to the Pr.178 to Pr.189 (Input terminal function selection) setting.

The AU signal need not be input.

Pr.128

setting

PID action

Additive

method

Set point input Measured value input

0PID invalid- - -

40 Reverse action

Fixed

Set by Pr.133 or Input by terminal

selected by Pr.609

Input by terminal selected by Pr.610

41 Forward action

42 Reverse action

Ratio

43 Forward action

Others Refer to page 501.

Power supply

MCCB

Inverter

Forward rotation

Reverse rotation

PID control selection

Main speed command

setting potentiometer

∗1

R/L1

S/L2

T/L3

STF

STR

RH(X14)

∗3

SD

10

2

5

4

∗4

U

V

W

∗2 (FUP)FU

SE

Motor

IM

Upper limit

∗2 (FDN)OL Lower limit

Output signal common

Feedback value of

dancer roll position

Loading...

Loading...