Causes and corrective actions

648

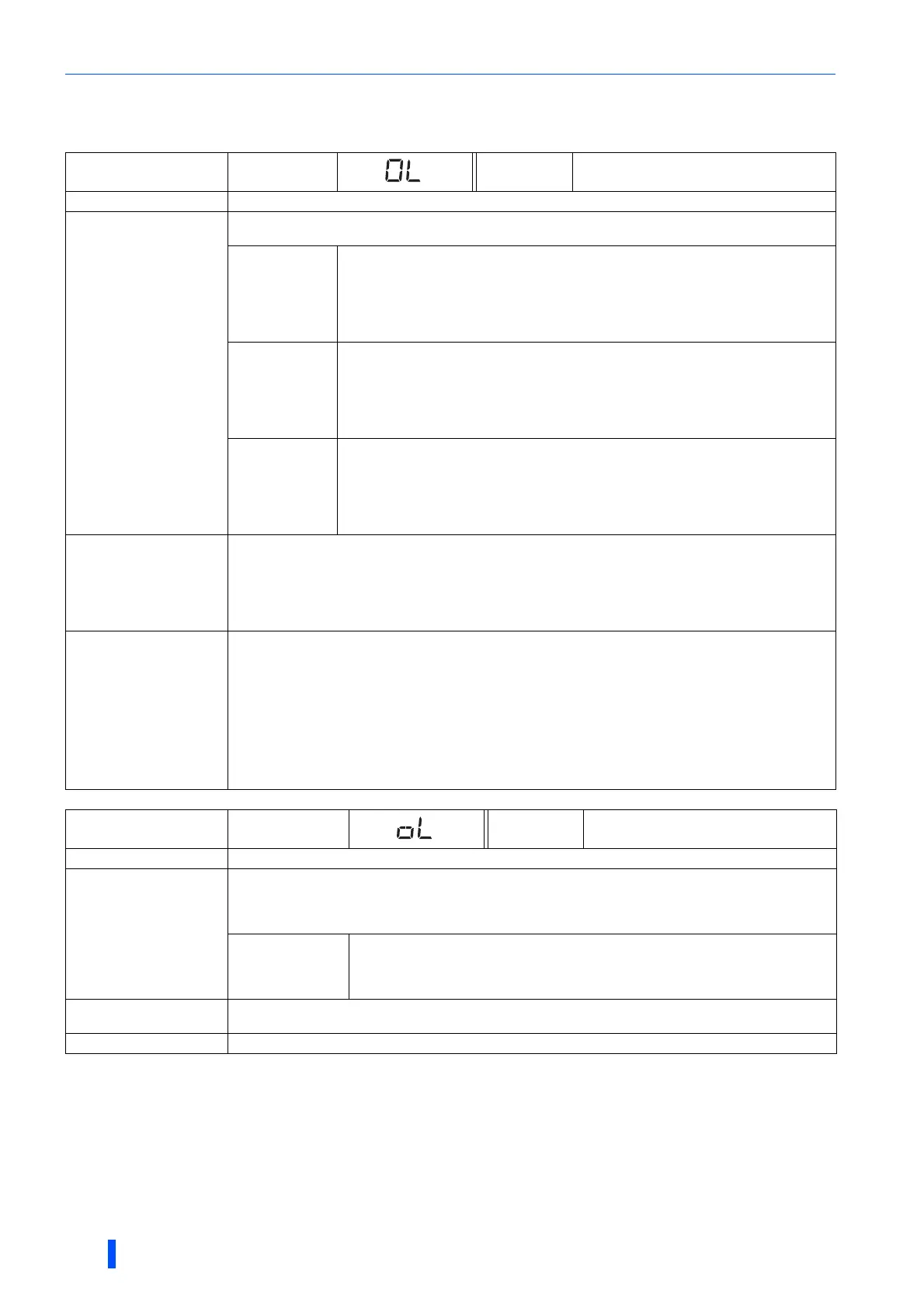

PROTECTIVE FUNCTIONS

Warning

Output is not shut off when a protective function activates.

Operation panel

indication

OL FR-PU07 OL

Name

Stall prevention (overcurrent)

Description

• When the output current of the inverter increases, the stall prevention (overcurrent) function activates.

• The following section explains about the stall prevention (overcurrent) function.

During

acceleration

When the output current (output torque under Real sensorless vector control or vector

control) of the inverter exceeds the stall prevention level (Pr.22 Stall prevention

operation level, etc.), this function stops the increase in frequency until the overload

current decreases to prevent the inverter from resulting in overcurrent trip. When the

overload current has reduced below stall prevention operation level, this function

increases the frequency again.

During

constant-speed

operation

When the output current (output torque under Real sensorless vector control or vector

control) of the inverter exceeds the stall prevention level (Pr.22 Stall prevention

operation level, etc.), this function reduces frequency until the overload current

decreases to prevent the inverter from resulting in overcurrent trip. When the overload

current has reduced below stall prevention operation level, this function increases the

frequency up to the set value.

During

deceleration

When the output current (output torque under Real sensorless vector control or vector

control) of the inverter exceeds the stall prevention level (Pr.22 Stall prevention

operation level, etc.), this function stops the decrease in frequency until the overload

current decreases to prevent the inverter from resulting in overcurrent trip. When the

overload current has decreased below stall prevention operation level, this function

decreases the frequency again.

Check point

• Check that the Pr.0 Torque boost setting is not too large.

• The Pr.7 Acceleration time and Pr.8 Deceleration time settings may be too short.

• Check that the load is not too heavy.

• Check for any failures in peripheral devices.

• Check that the Pr.13 Starting frequency is not too large.

• Check that Pr.22 Stall prevention operation level is appropriate.

Corrective action

• Gradually increase or decrease the Pr.0 setting by 1% at a time and check the motor status.(Refer to

page 597.)

• Set a larger value in Pr.7 Acceleration time and Pr.8 Deceleration time. (Refer to page 285.)

• Reduce the load.

• Try Advanced magnetic flux vector control, Real sensorless vector control, or vector control.

• Change the Pr.14 Load pattern selection setting.

• The stall prevention operation current can be set in Pr.22 Stall prevention operation level. (Initial value is

150%.) The acceleration/deceleration time may change. Increase the stall prevention operation level with

Pr.22 Stall prevention operation level, or disable stall prevention with Pr.156 Stall prevention operation

selection. (Use Pr.156 to set either operation continued or not at OL operation.)

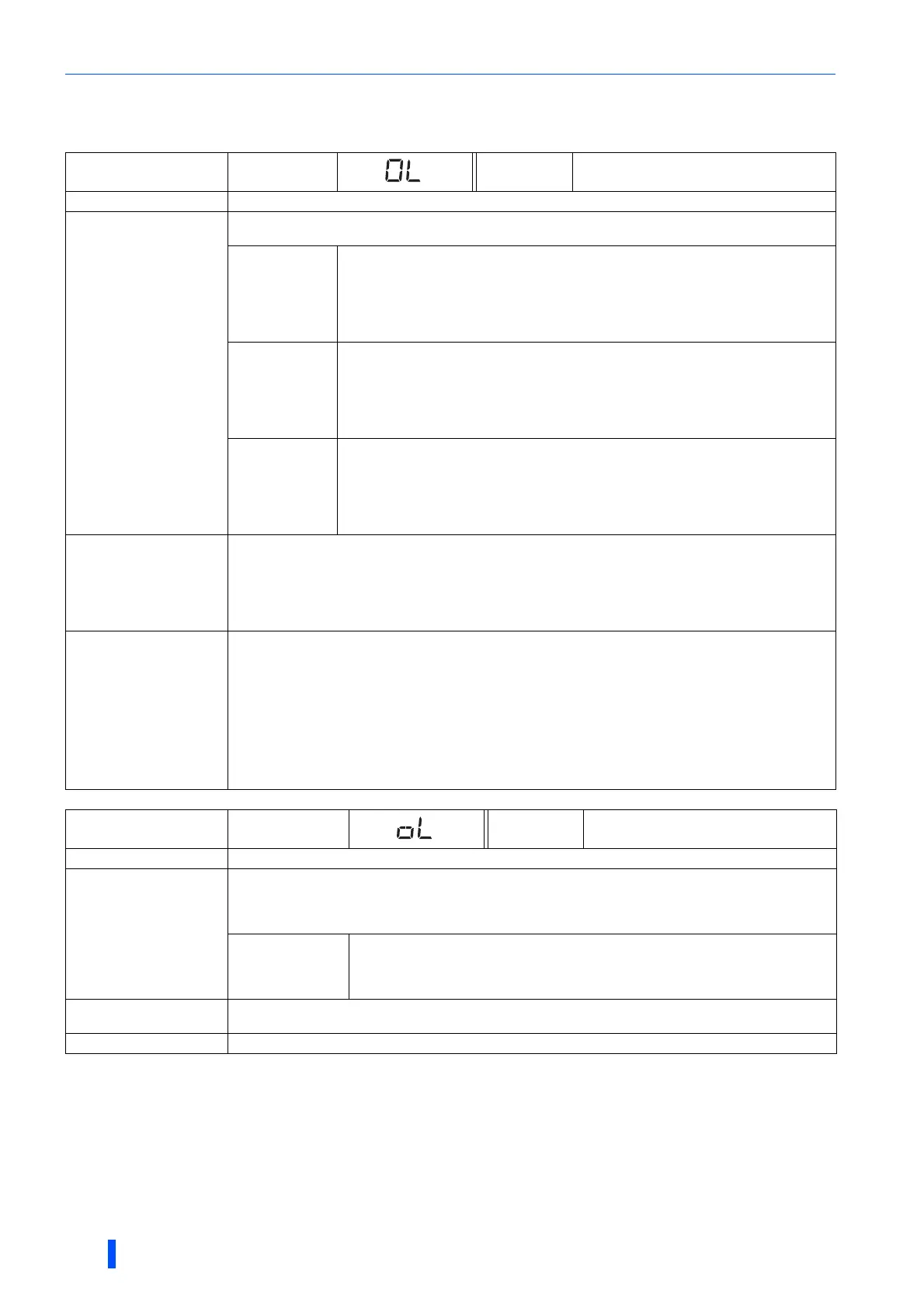

Operation panel

indication

oL FR-PU07 oL

Name

Stall prevention (overvoltage)

Description

• When the output voltage of the inverter increases, the stall prevention (overvoltage) function activates.

• The regeneration avoidance function activates due to excessive regenerative power of the motor. (Refer to

page 621.)

• The following section explains the stall prevention (overvoltage) function.

During deceleration

If the regenerative power of the motor becomes excessive to exceed the regenerative

power consumption capability, this function stops decreasing the frequency to prevent

overvoltage trip. As soon as the regenerative power has reduced, deceleration

resumes.

Check point

• Check for sudden speed reduction.

• Check if the regeneration avoidance function (Pr.882 to Pr.886) is being used. (Refer to page 621.)

Corrective action

The deceleration time may change. Increase the deceleration time using Pr.8 Deceleration time.

Loading...

Loading...