Check first when you have a trouble

664

PROTECTIVE FUNCTIONS

6.6 Check first when you have a trouble

For Real sensorless vector control and vector control, also refer to the troubleshooting on page 198 (speed control), page 226

(torque control), and page 252 (position control).

NOTE

• If the cause is still unknown after every check, it is recommended to initialize the parameters, set the required parameter

values and check again.

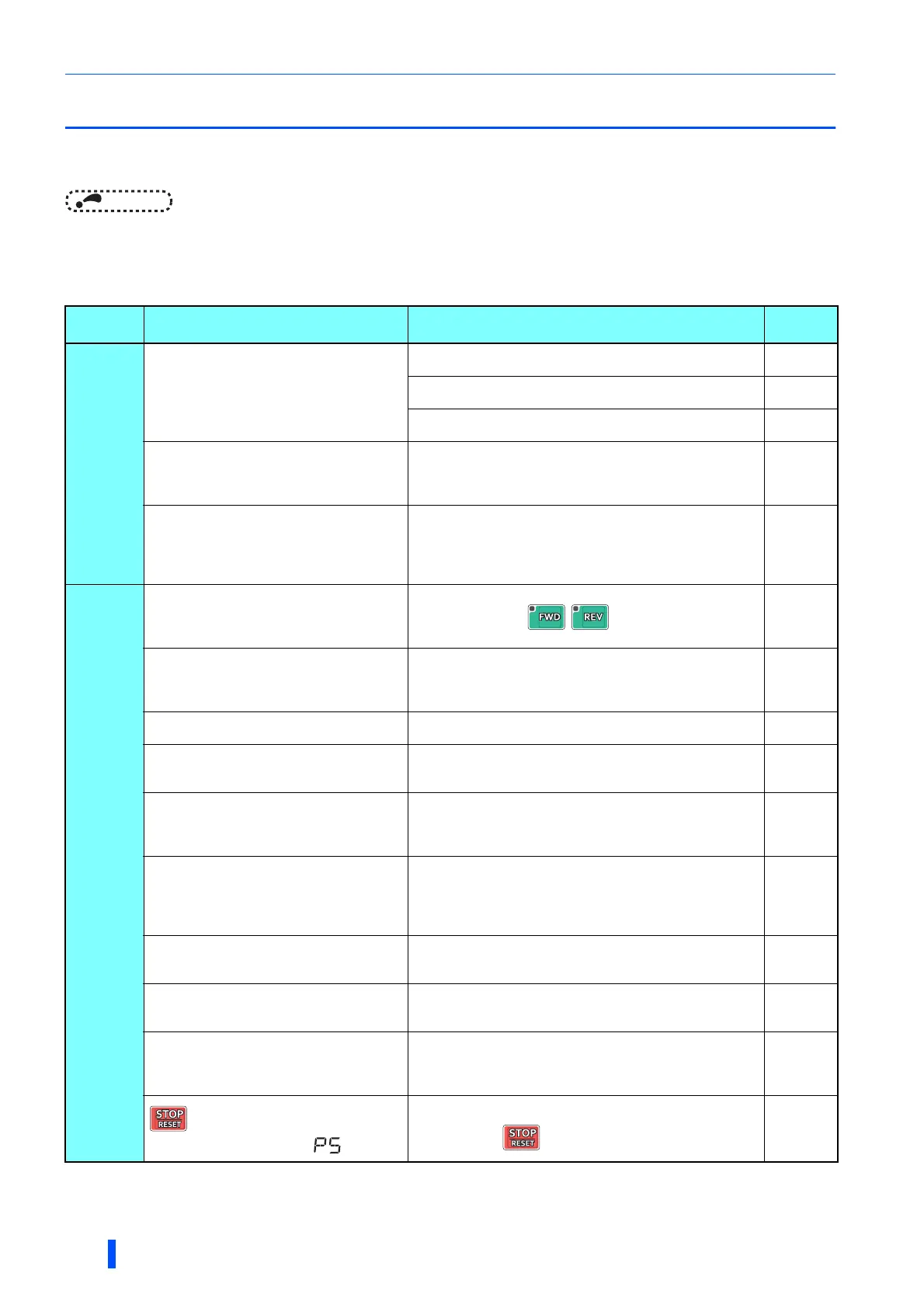

6.6.1 Motor does not start

Check

points

Possible cause Countermeasure

Refer to

page

Main

Circuit

Appropriate power supply voltage is not

applied.

(Operation panel display is not provided.)

Power on a molded case circuit breaker (MCCB), an earth

leakage circuit breaker (ELB), or a magnetic contactor (MC).

Check for the decreased input voltage, input phase loss, and

wiring.

If only the control power is ON when using a separate power

source for the control circuit, turn ON the main circuit power.

54

Motor is not connected properly.

Check the wiring between the inverter and the motor.

If the electronic bypass function is active, check the wiring of

the magnetic contactor (MC) between the inverter and the

motor.

38

The jumper across P/+ to P1 is disconnected.

A DC reactor (FR-HEL) is not connected.

Securely fit a jumper across P/+ and P1.

When using a DC reactor (FR-HEL), remove the jumper across

P/+ to P1, and then connect the DC reactor.

Connect the DC reactor securely when required according to

the capacity.

38, 79

Input

signal

Start signal is not input.

Check the start command source, and input a start signal.

PU operation mode: /

External operation mode: STF/STR signal

309

Both the forward and reverse rotation start

signals (STF, STR) are input simultaneously.

Turn ON only one of the forward and reverse rotation start

signals (STF or STR).

When the STF and STR signals are turned ON simultaneously

in the initial setting, a stop command is given.

45

Frequency command is zero. (FWD or REV

LED on the operation panel is flickering.)

Check the frequency command source and enter a frequency

command.

309

AU signal is not ON when terminal 4 is used

for frequency setting. (FWD or REV LED on

the operation panel is flickering.)

Turn ON the AU signal.

Turning ON the AU signal activates terminal 4 input.

406

Output stop signal (MRS) or reset signal

(RES) is ON. (FWD or REV LED on the

operation panel is flickering.)

Turn MRS or RES signal OFF.

Inverter starts the operation with a given start command and a

frequency command after turning OFF MRS or RES signal.

Before turning OFF, ensure the safety.

45

CS signal is OFF while the automatic restart

after instantaneous power failure function is

selected (Pr.57 Restart coasting time

9999). (FWD or REV LED on the operation

panel is flickering.)

Turn ON the automatic restart after instantaneous power

failure/flying start (CS) signal.

When the CS signal is assigned to an input terminal, automatic

restart operation is enabled when the CS signal is turned ON.

528

Jumper connector of sink - source is

incorrectly selected. (FWD or REV LED on the

operation panel is flickering.)

Check that the control logic switchover jumper connector is

correctly installed.

If it is not installed correctly, input signal is not recognized.

49

Wiring of encoder is incorrect.

(Under encoder feedback control or vector

control)

Check the wiring of encoder. 65

Voltage/current input switch is not correctly set

for analog input signal (0 to 5 V/0 to 10 V, 4 to

20 mA). (FWD or REV LED on the operation

panel is flickering.)

Set Pr.73 Analog input selection, Pr.267 Terminal 4 input

selection, and a voltage/current input switch correctly, then

input an analog signal in accordance with the setting.

406

was pressed.

(Operation panel indication is (PS).)

During the External operation mode, check the

method of

restarting from a input stop from PU

.

260, 649

Loading...

Loading...