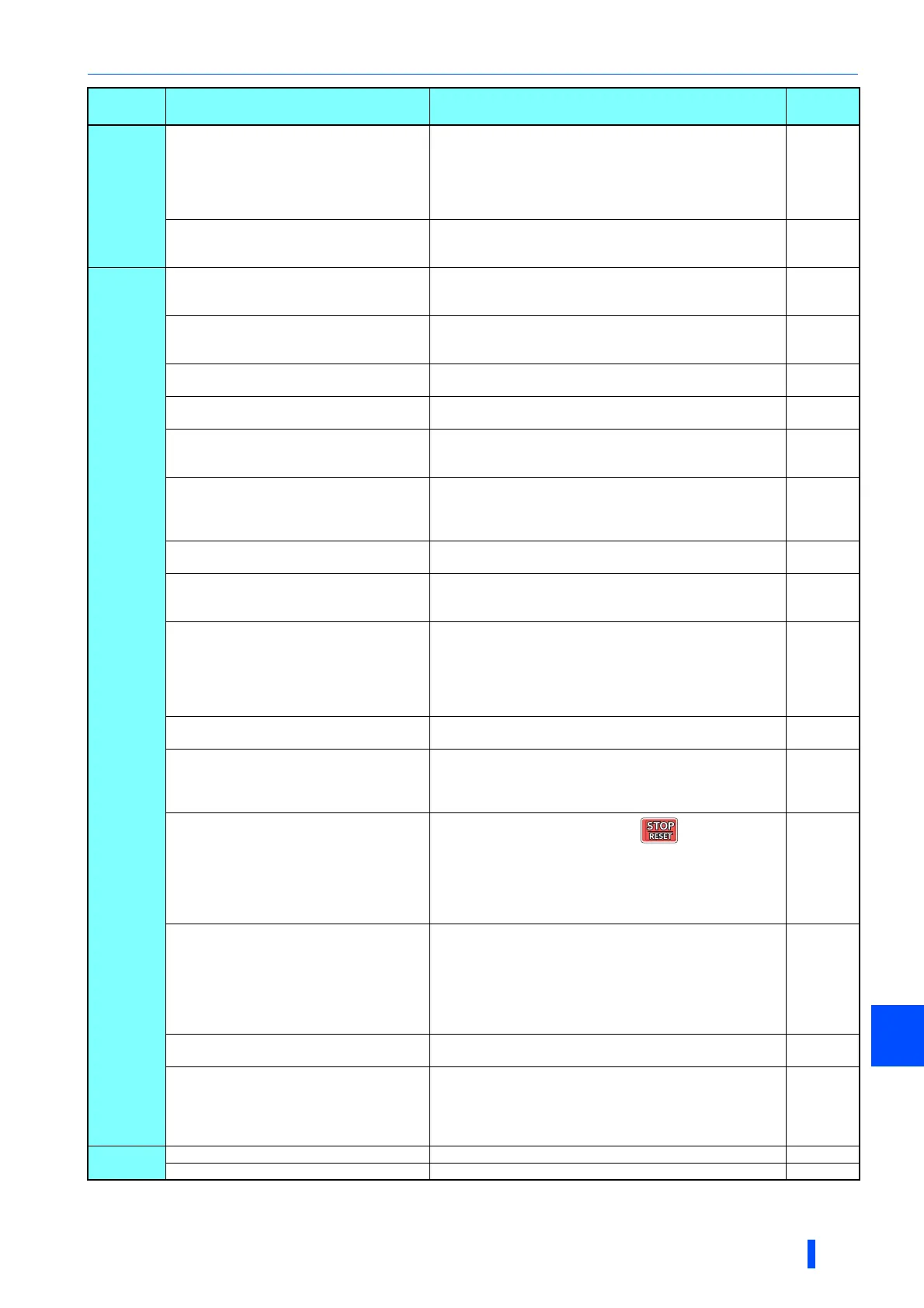

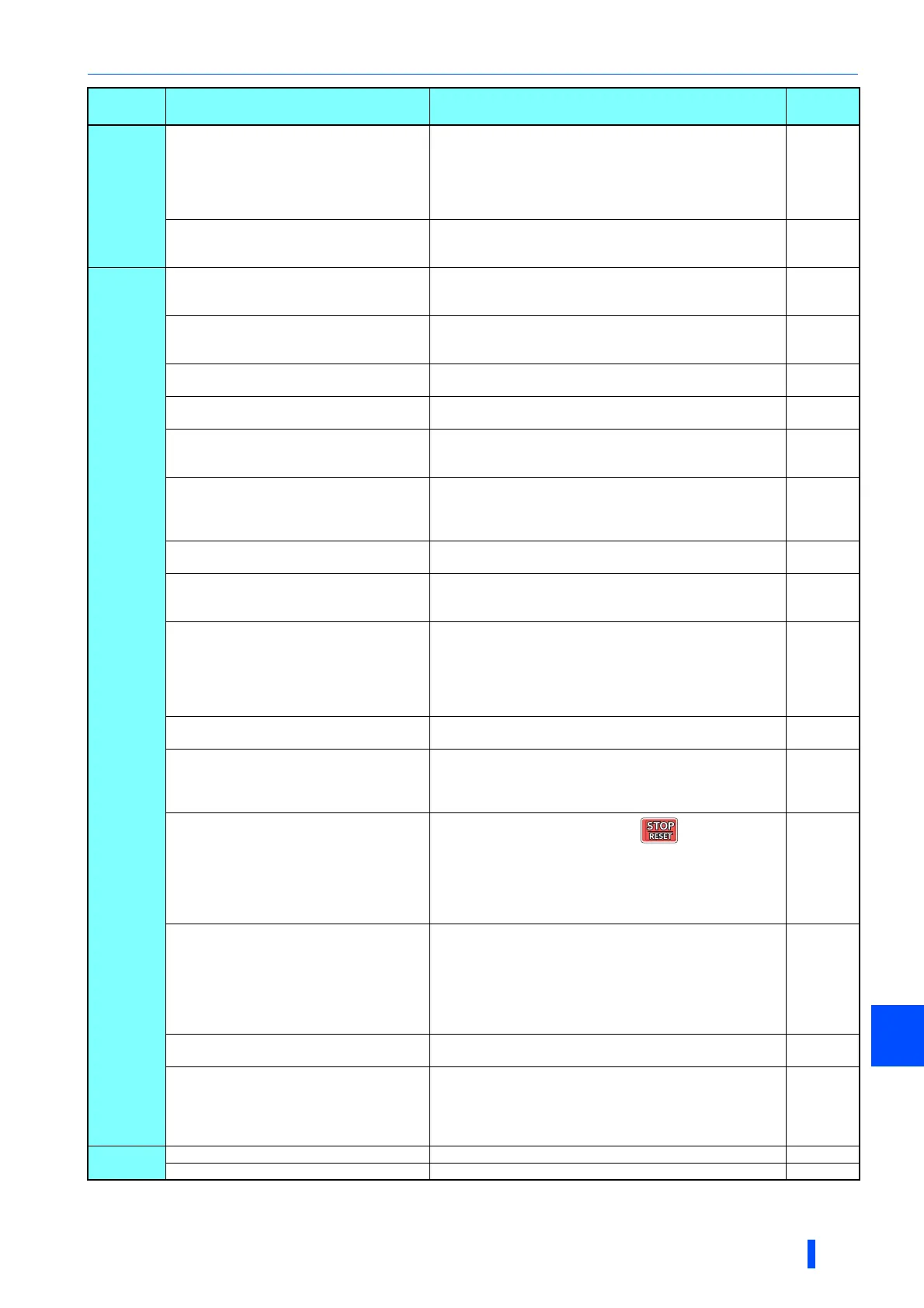

Check first when you have a trouble

PROTECTIVE FUNCTIONS

665

6

Input

signal

For the separated converter type, terminals

RDA and SE of the converter unit are not

connected to terminals MRS (X10 signal) and

SD (PC for source logic) of the inverter

respectively.

Check for the wiring.

Refer to the

Instruction

Manual

(Hardware)

of the FR-

A802.

Two-wire or three-wire type connection is

incorrect.

Check the wiring.

Use the Start self-holding selection (STP (STOP)) signal when

the three-wire type is used.

436

Parameter

Setting

Under V/F control, Pr.0 Torque boost setting

is improper.

Increase the Pr.0 setting by 0.5% increments while observing

the rotation of a motor.

If that makes no difference, decrease the setting.

597

Pr.78 Reverse rotation prevention selection

is set.

Check the Pr.78 setting.

Set Pr.78 when you want to limit the motor rotation to only one

direction.

323

Pr.79 Operation mode selection setting is

incorrect.

Select the operation mode which corresponds with input

methods of start command and frequency command.

306

Bias and gain (calibration parameter C2 to

C7) settings are improper.

Check the bias and gain (calibration parameter C2 to C7)

settings.

415

Pr.13 Starting frequency setting is greater

than the running frequency.

Set running frequency higher than Pr.13.

The inverter does not start if the frequency setting signal is less

than the value set in Pr.13.

298, 299

Frequency settings of various running

frequency (such as multi-speed operation) are

zero.

Especially, Pr.1 Maximum frequency is zero.

Set the frequency command according to the application.

Set Pr.1 higher than the actual frequency used.

328, 345

Pr.15 Jog frequency is lower than Pr.13

Starting frequency for JOG operation.

Set Pr.15 higher than Pr.13.

298, 299,

327

The Pr.359 Encoder rotation direction

setting is incorrect under encoder feedback

control or under vector control.

If the "REV" on the operation panel is lit even though the

forward-rotation command is given, set Pr.359 = "1".

68, 626

Operation mode and a writing device do not

correspond.

Check Pr.79 Operation mode selection, Pr.338

Communication operation command source, Pr.339

Communication speed command source, Pr.550 NET mode

operation command source selection and Pr.551 PU mode

operation command source selection, and select an

operation mode suitable for the purpose.

306,

316

S

tart sign

al operation selection is set by

Pr.250 Stop selection.

Check the Pr.250 setting and the connection of STF and STR

signals.

436

The motor has decelerated to a stop when

power failure deceleration stop function is

selected.

When power is restored, ensure the safety, and turn OFF the

start signal once, then turn ON again to restart.

When Pr.261 Power failure stop selection = "2 or 12", the

motor automatically restarts after the power is restored.

540

Performing auto tuning.

When offline auto tuning ends, press of the operation

panel for the PU operation. For the External operation, turn

OFF the start signal (STF or STR).

This operation resets the offline auto tuning, and the PU's

monitor display returns to the normal indication.

(Without this operation, next operation cannot be started.)

442, 537

The automatic restart after instantaneous

power failure function or power failure stop

function has been activated.

(Performing overload operation during input

phase loss may cause voltage insufficiency,

and that may result in detection of power

failure.)

Set Pr.872 Input phase loss protection selection ="1" (input

phase failure protection active).

Disable the automatic restart after instantaneous power failure

function and power failure stop function.

Reduce the load.

Increase the acceleration time if the function was activated

during acceleration.

342, 528,

534, 540

The motor test operation is selected under

vector control or PM sensorless vector control.

Check the Pr.800 Control method selection setting. 164

When the FR-HC2, FR-CV, or FR-CC2 is

used, the input logic setting of the X10 signal

is incorrect.

Set Pr.599="0" (initial value for standard models and IP55

compatible models) to use the X10 signal with the NO contact

input specification, and Pr.599="1" (initial value for separated

converter types) to use the X10 signal with the NC contact input

specification.

614

Load

Load is too heavy. Reduce the load.

Shaft is locked. Inspect the machine (motor).

Check

points

Possible cause Countermeasure

Refer to

page

Loading...

Loading...