(A) Application parameters

522

PARAMETERS

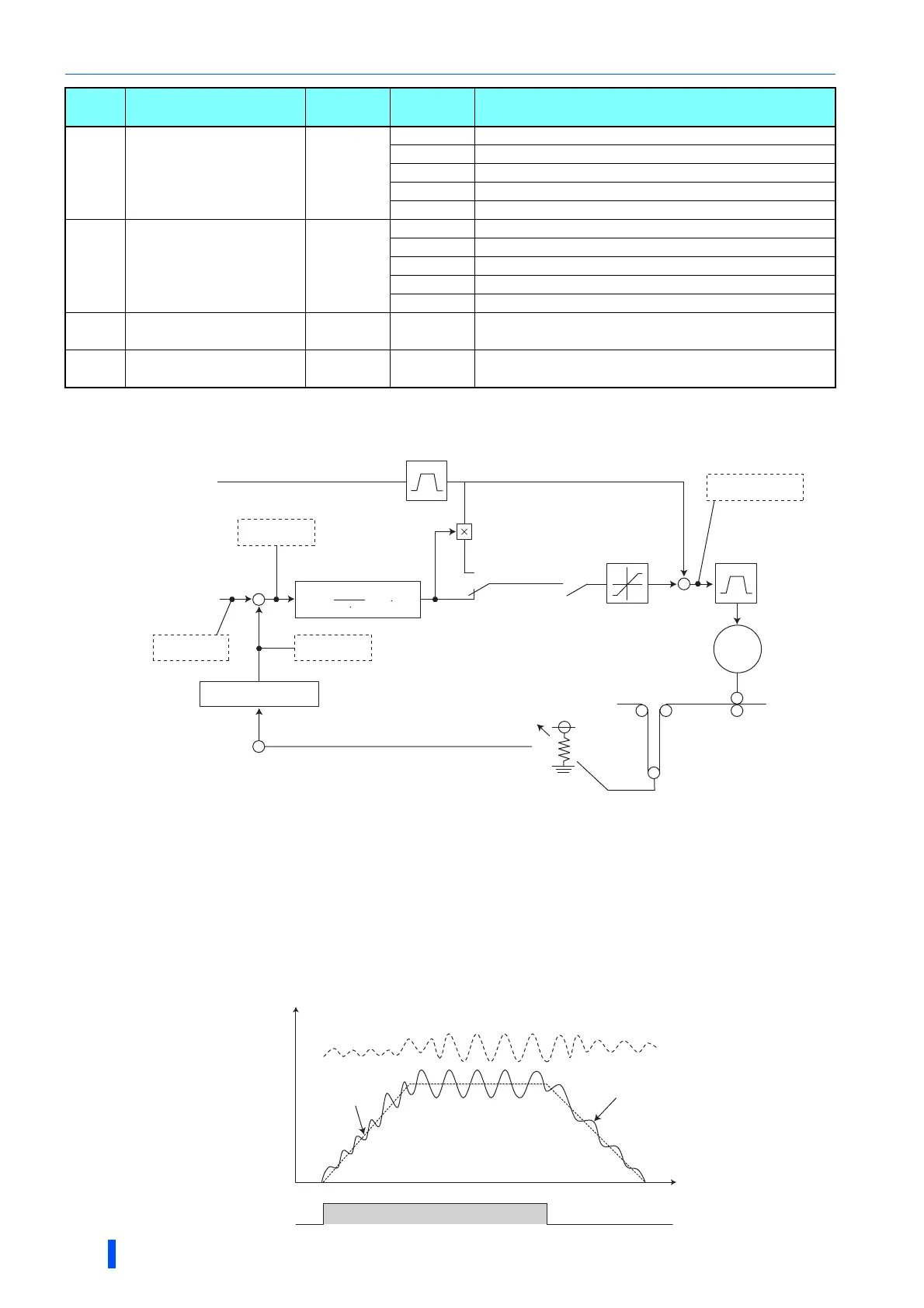

Block diagram of dancer control

The main speed can be selected in all operation modes, External (analog voltage input, multi-speed), PU (digital frequency setting) and

Communication (RS-485).

Outline of dancer control

• Dancer control is performed by setting "40 to 43" in Pr.128 PID action selection. The main speed command is the speed

command for each operation mode (External, PU and communication). PID control is performed by the dancer roll position

detection signal, and the control result is added to the main speed command. For the main speed acceleration/deceleration

time, set the acceleration time to Pr.44 Second acceleration/deceleration time and the deceleration time to Pr.45

Second deceleration time.

609

A624

PID set point/deviation

input selection

2

1 Input set point from terminal 1

2 Input set point from terminal 2

3 Input set point from terminal 4

4 Input set point via CC-Link communication

5 Input set point by PLC function

610

A625

PID measured value

input selection

3

1 Input measured value from terminal 1

2 Input measured value from terminal 2

3 Input measured value from terminal 4

4 Input measured value via CC-Link communication

5 Input measured value by PLC function

1134

A605

PID upper limit

manipulated value

100% 0 to 100% Set the upper limit of PID action.

1135

A606

PID lower limit

manipulated value

100% 0 to 100% Set the lower limit of PID action.

Pr. Name

Initial

value

Setting

range

Description

Limit

Ratio

Acceleration/deceleration

of main speed

Main speed command

∗1

Dancer roll

setting point

Pr.133

Terminal 4

Potentiometer

Dancer roll position detection

PID control

PID deviation

PID feedback

PID set point

Target frequency

X14

Pr.128 = 40, 41

Pr.128 = 42, 43

Acceleration/

deceleration

+

-

Kp(1+ +Td S)

Ti S

1

Convert to 0 to 100%

IM

+

+

STF

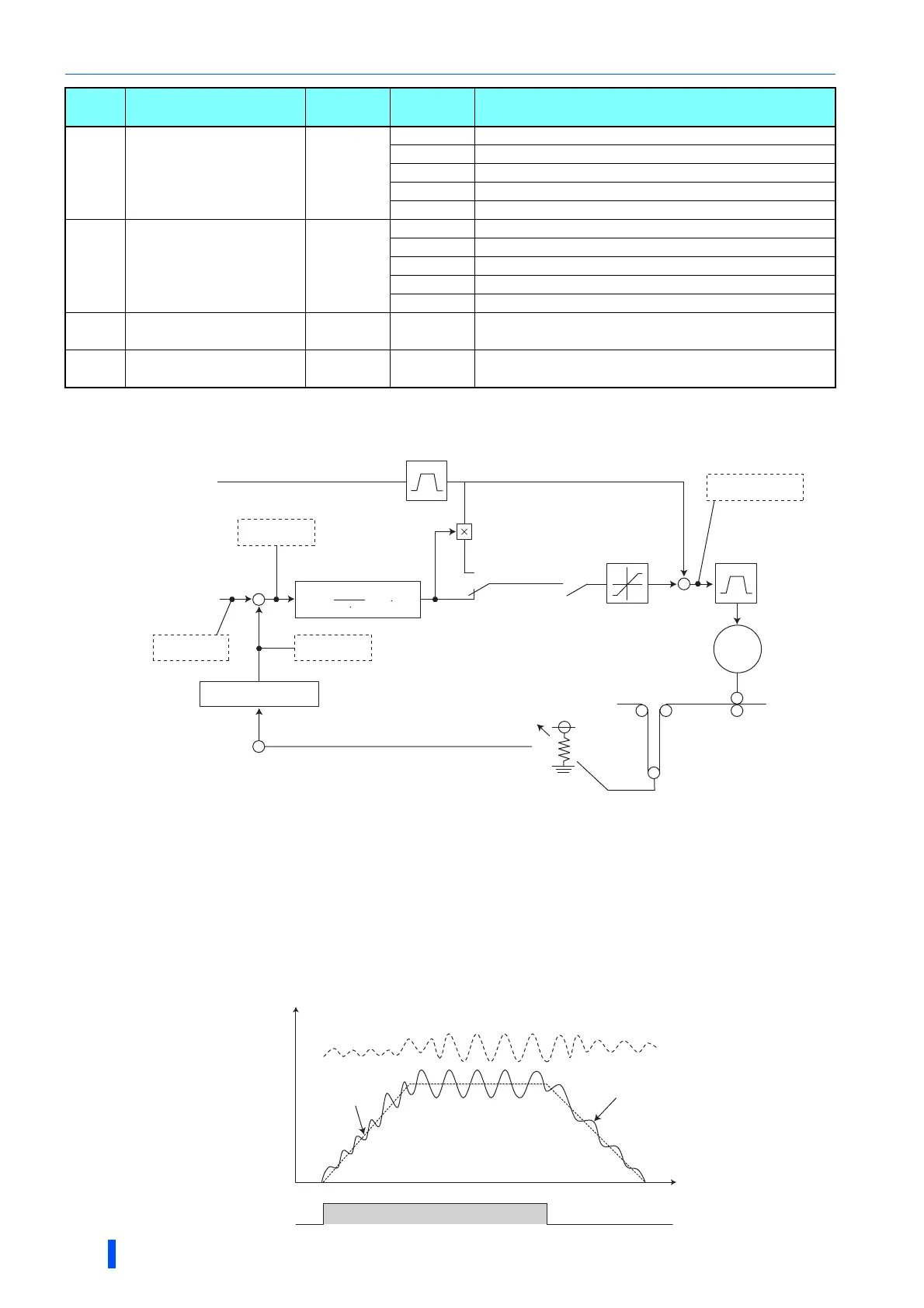

PID adding value

Main speed

ON

Output frequency

Time

Output frequency

Loading...

Loading...