Torque control under Real sensorless vector control and vector control

PARAMETERS

217

5

Torque command by parameter (Pr.804="1")

• Torque command values can be set by setting Pr.805 Torque command value (RAM) and Pr.806 Torque command

value (RAM,EEPROM).

•For Pr.805 or Pr.806, regard 1000% as 0%, and set torque command by offset from 1000%.

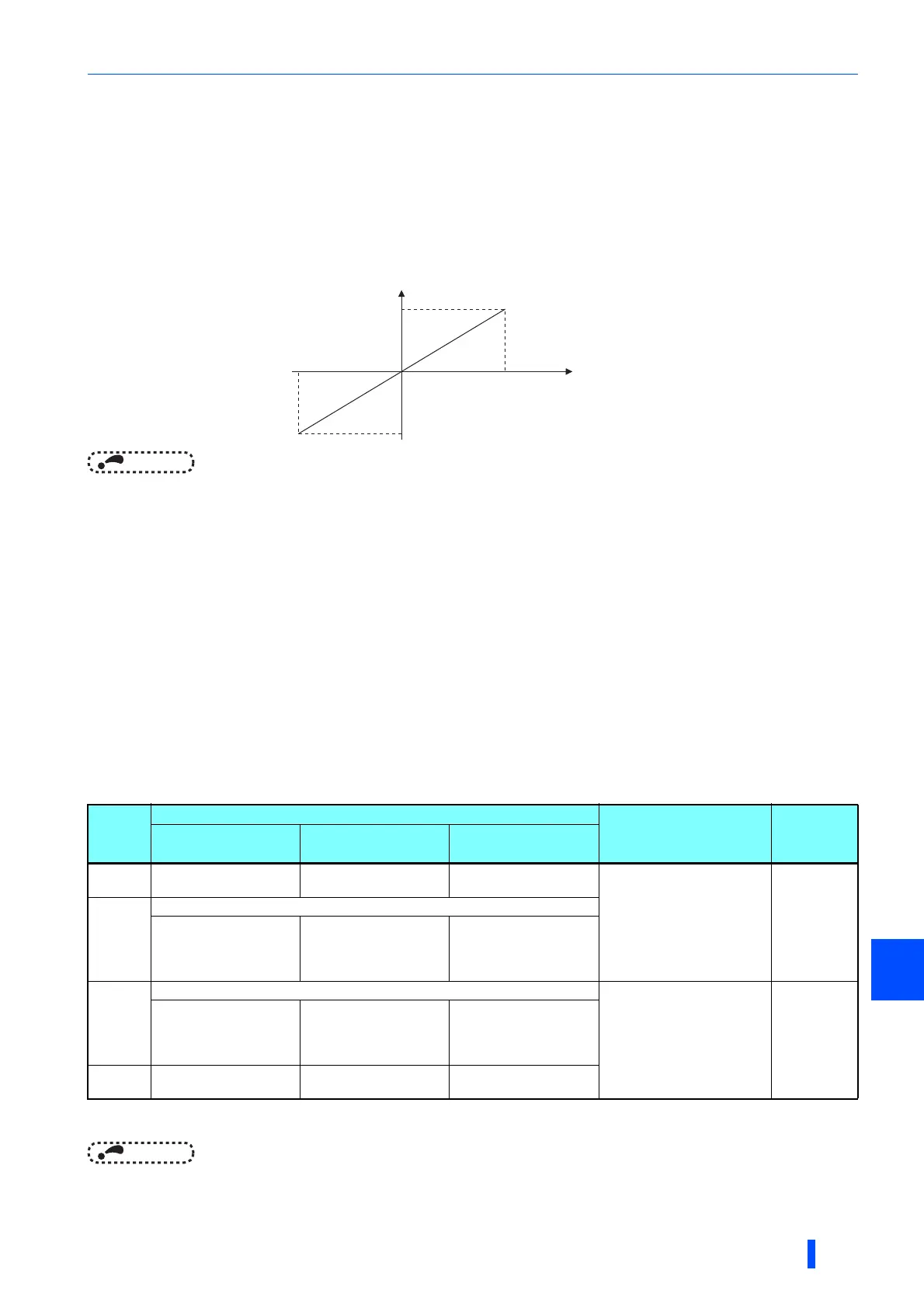

The following diagram shows relation between the Pr.805 or Pr.806 setting and the actual torque command value.

• To change torque command value frequently, write in Pr.805. If values are written in Pr.806 frequently, EEPROM life is

shortened.

• When FR-A8NCE (CC-Link IE Field communication option) is mounted, torque command from FR-A8NCE is enabled.

NOTE

• When the torque command is set by Pr.805 (RAM), powering OFF the inverter will erase the changed parameter value.

Therefore,the parameter set value will be the one saved by Pr.806 (EEPROM) when the power is turned back on.

• If providing torque command by parameter setting, set the speed limit value properly to prevent overspeeding. (Refer to page

219.)

Torque command via CC-Link communication or PROFIBUS-DR

communication (Pr.804="3, 5, or 6")

• Torque command values can be set via CC-Link communication (FR-A8NC / PLC function), the CC-Link IE Field

communication option (FR-A8NCE), or the PROFIBUS-DR communication option (FR-A8NP).

• If the CC-Link communication is used with Pr.804="3 or 5", Pr.807 Speed limit selection is invalid and Pr.808 Forward

rotation speed limit/speed limit and Pr.809 Reverse rotation speed limit/reverse-side speed limit are valid. (When

Pr.544 CC-Link extended setting="0, 1, 12, 100, or 112")

• For the CC-Link communication, Pr.807 is valid when the extended cyclic setting of CC-Link communication is quadruple or

octuple. For the FR-A8NCE, Pr.807 is always valid.

Can also be set from operation panel or parameter unit.

Setting range if set by operation panel or parameter unit is "673 to 1327 (-327% to 327%)"; setting increment is 1%.

NOTE

• For the details of FR-A8NC, FR-A8NCE, FR-A8NP setting, refer to the Instruction Manual for the respective communication

options.

• For the details of the setting using the PLC function, refer to the PLC Function Programming Manual.

Pr.804

setting

Torque command input

Setting range

Setting

increments

FR-A8NC

PLC function

FR-A8NCE FR-A8NP

1

Torque command by

Pr.805, Pr.806

Same operation as the

setting value "3"

Torque command by

Pr.805, Pr.806

600 to 1400 (-400% to

400%)

1%

3

Torque command by Pr.805, Pr.806

Torque command by

remote register (RWw1

or RWwC)

Torque command by

remote register (RWw2

or RWw3)

Torque command by the

buffer memory of

PROFIBUS-DP (REF1

to 7)

5

Torque command by Pr.805, Pr.806

-32768 to 32767

(complement of 2)

(-327.68% to 327.67%)

0.01%

Torque command by

remote register (RWw1

or RWwC)

Torque command by

remote register (RWw2

or RWw3)

Torque command by the

buffer memory of

PROFIBUS-DP (REF1

to 7)

6

Torque command by

Pr.805, Pr.806

Same operation as

setting value "5"

Torque command by

Pr.805, Pr.806

Torque command value

400%

600%

1000% 1400%

-400%

Pr.805, Pr.806

settings

Torque command value

=Pr.805(or Pr.806)-1000%

Loading...

Loading...