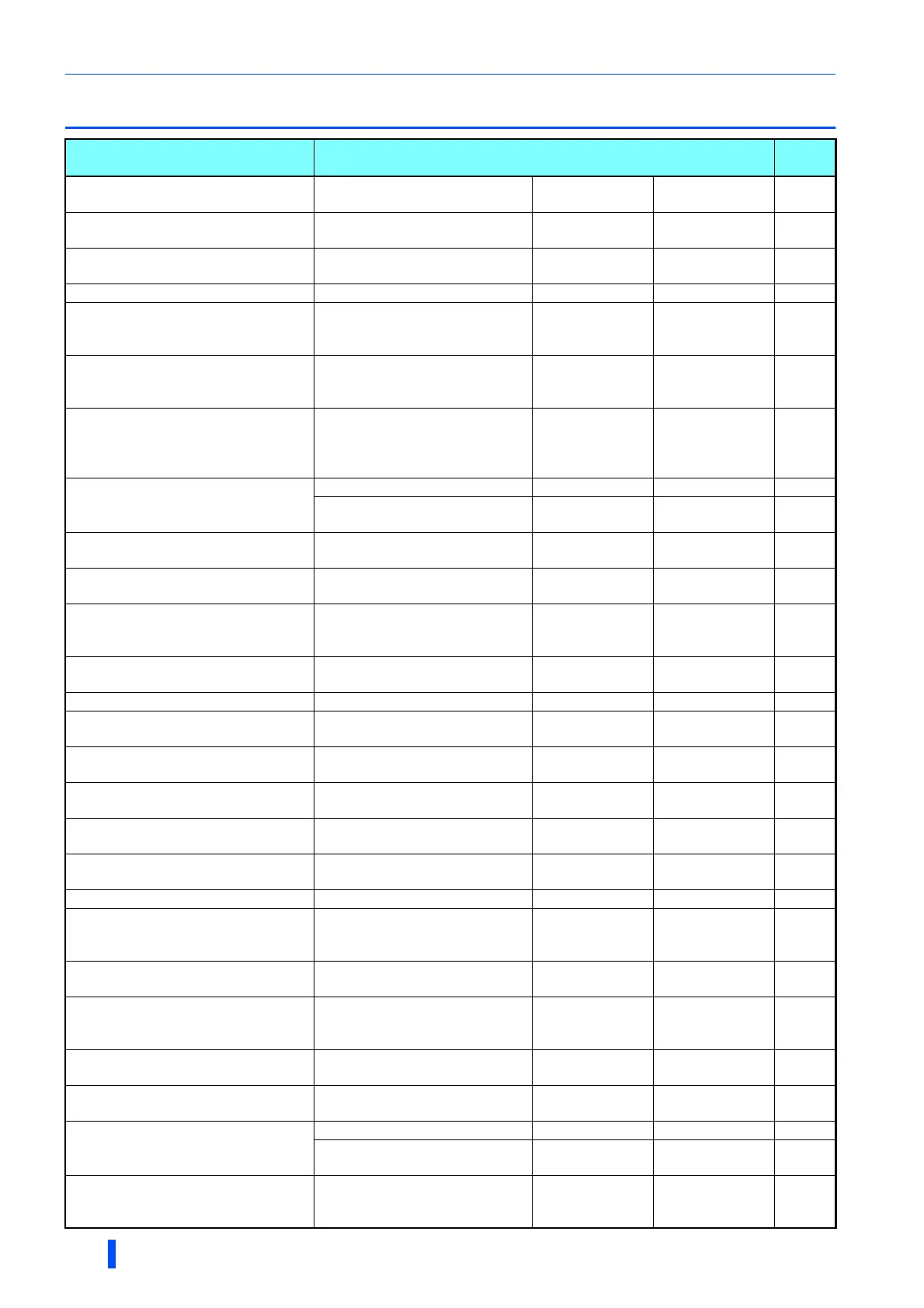

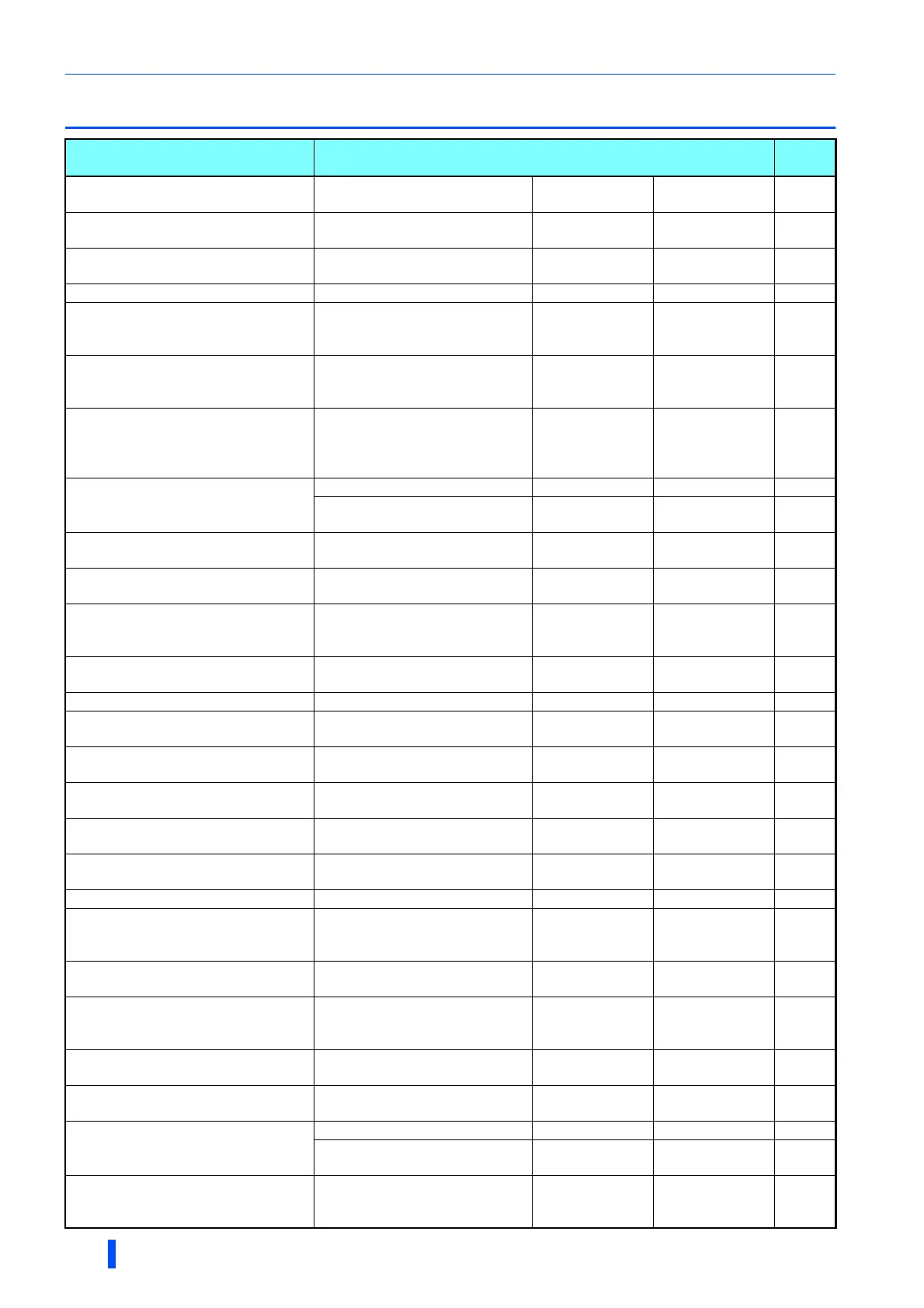

(G) Control parameters

596

PARAMETERS

5.16 (G) Control parameters

Purpose Parameter to set

Refer

to page

To set the starting torque manually Manual torque boost

P. G 0 0 0 , P. G 0 1 0 ,

P. G 02 0

Pr.0, Pr.46,

Pr.112

597

To set the motor constant

Base frequency, base

frequency voltage

P. G 0 0 1 , P. G 0 0 2 ,

P.G011, P.G021

Pr.3, Pr.19,

Pr.47, Pr.113

598

To select the V/F pattern matching

the application

Load pattern selection P.G003 Pr.14 600

To perform energy saving operation Energy saving operation P.G030 Pr.60 602

To use a special motor Adjustable 5 points V/F

P.C100,

P. G 0 4 0 t o

P. G 04 9

Pr.71,

Pr.100 to Pr.109

603

To compensate the motor slip

amount when replacing an SF-JR

motor with an SF-PR motor

SF-PR slip amount adjustment

mode

P.G060, P.G061 Pr.673, Pr.674 604

To adjust the motor braking torque

DC injection brake, zero speed

control, and servo lock,

magnetic flux decay output

shutoff

P. G 1 0 0 t o

P. G 1 0 3 , P. G 11 0

Pr.10 to Pr.12,

Pr.802, Pr.850

605

To coast the motor to a stop

Output stop function P.G105 Pr.522 611

Selection of motor stop

method

P.G106 Pr.250 613

To use the regeneration unit to

increase the motor braking torque

Regenerative brake selection

P.E300, P.G107,

P. T 72 1

Pr.30, Pr.70,

Pr.599

614

To operate the inverter with DC

power supply

DC feeding mode P.E300 Pr.30 614

To avoid overvoltage alarm due to

regenerative driving by automatic

adjustment of the output frequency

Regeneration avoidance

function

P. G 1 2 0 t o

P. G 12 5

Pr.882 to Pr.886,

Pr.665

621

To decrease the deceleration time

of the motor

Increased magnetic excitation

deceleration

P. G 1 3 0 t o

P. G 13 2

Pr.660 to Pr.662 624

To select the control method Control method selection P.G200, P.G300 Pr.800, Pr.451 164

To secure the low-speed torque by

compensating the slip of the motor

Slip compensation

P. G 2 0 3 t o

P. G 20 5

Pr.245 to Pr.247 625

To select the torque characteristic

Constant output range torque

characteristic selection

P.G210 Pr.803

185,

216

To adjust the speed control gain Speed control gain

P.G211, P.G212

P.G311, P.G312

Pr.820, Pr.821,

Pr

.830, Pr.831

192

T

o adjust the torque control gain Torque control gain

P. G 2 1 3 , P. G 2 1 4 ,

P. G 3 1 3 , P. G 3 1 4

Pr.824, P.825,

Pr.834, P.835

225

To stabilizes speed and torque

feedback signal

Speed detection filter,

torque detection filter

P. G 2 1 5 , P. G 2 1 6 ,

P. G 3 1 5 , P. G 3 1 6

Pr.823, Pr.827,

Pr.833, Pr.837

254

To changes excitation ratio Excitation ratio P.G217 Pr.854 255

To improve the motor trackability

for the speed command changes

Speed feed forward control,

model adaptive speed control

P. G 2 2 4 , P. G 2 2 0

to P.G222,

P. G 22 3

Pr.828,

Pr.877 to Pr.879,

Pr.881

200

To make starting torque start-up

faster

Torque bias

P. G 2 3 0 t o

P. G 23 8

Pr.840 to Pr.848 202

To make the motor speed constant

by the encoder

Encoder feedback control

P. M 0 0 2 , P. A 1 0 7 ,

P.C140, P.C141,

P. G 2 4 0 , P. G 2 4 1

Pr.144, Pr.285,

Pr.359,

Pr.367 to Pr.369

626

To select low-speed range torque

characteristics

Low-speed range torque

characteristics

P.G250, P.G350 Pr.788, Pr.747 176

To perform frequency control

appropriate for load torque

Droop control

P. G 4 0 0 t o

P. G 40 4

Pr.286 to Pr.288,

Pr.994, Pr.995

628

To suppress the machine

resonance

Speed smoothing control P.G410, P.G411 Pr.653, Pr.654 630

Notch filter

P. G 6 0 1 t o

P. G 60 3

Pr.1003 to

Pr.1005

208

To adjust the speed gain for

Advanced magnetic flux vector

control

Speed control gain P.G932, P.G942 Pr.89, Pr.569 170

Loading...

Loading...