Check first when you have a trouble

668

PROTECTIVE FUNCTIONS

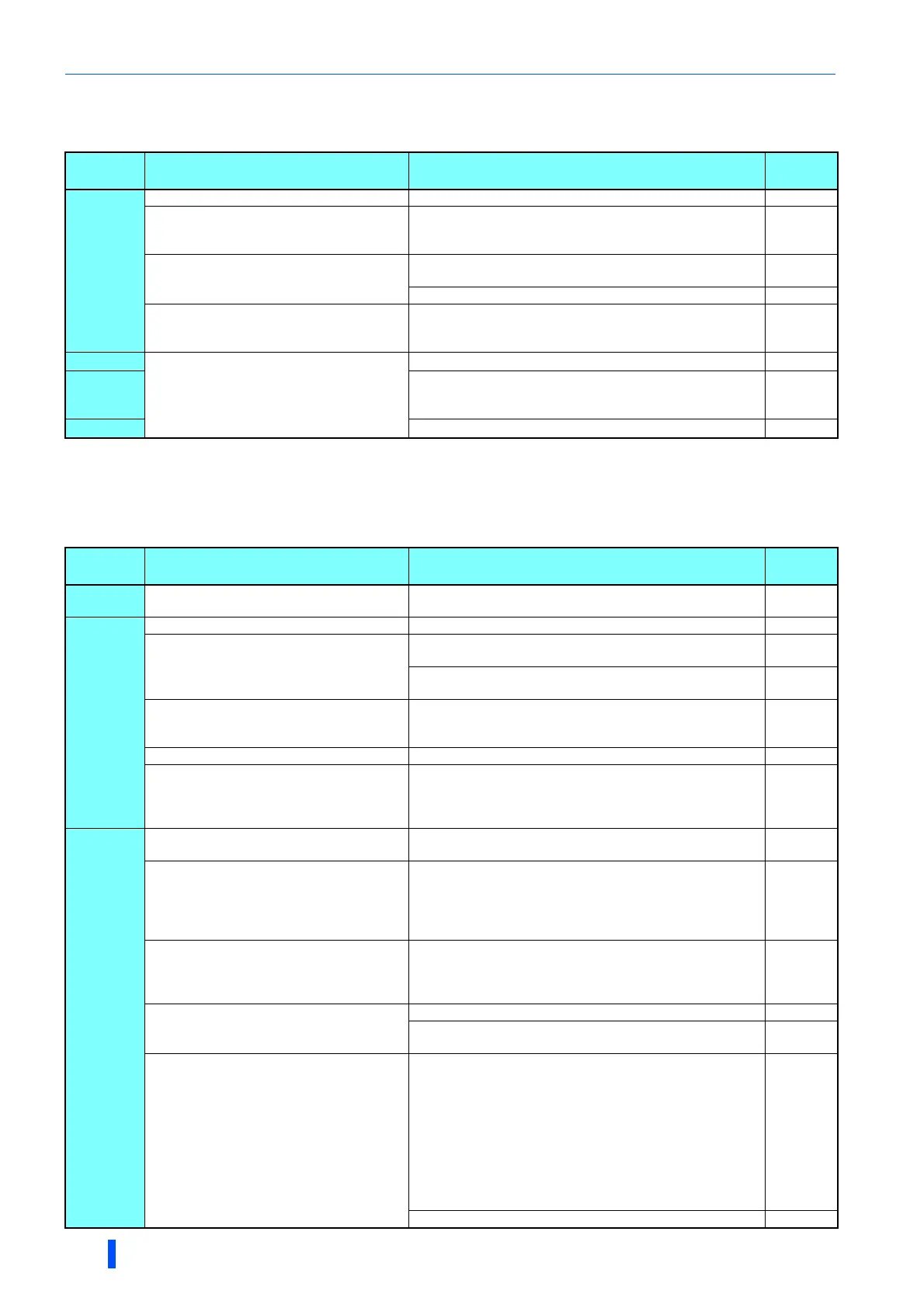

6.6.7 Acceleration/deceleration is not smooth

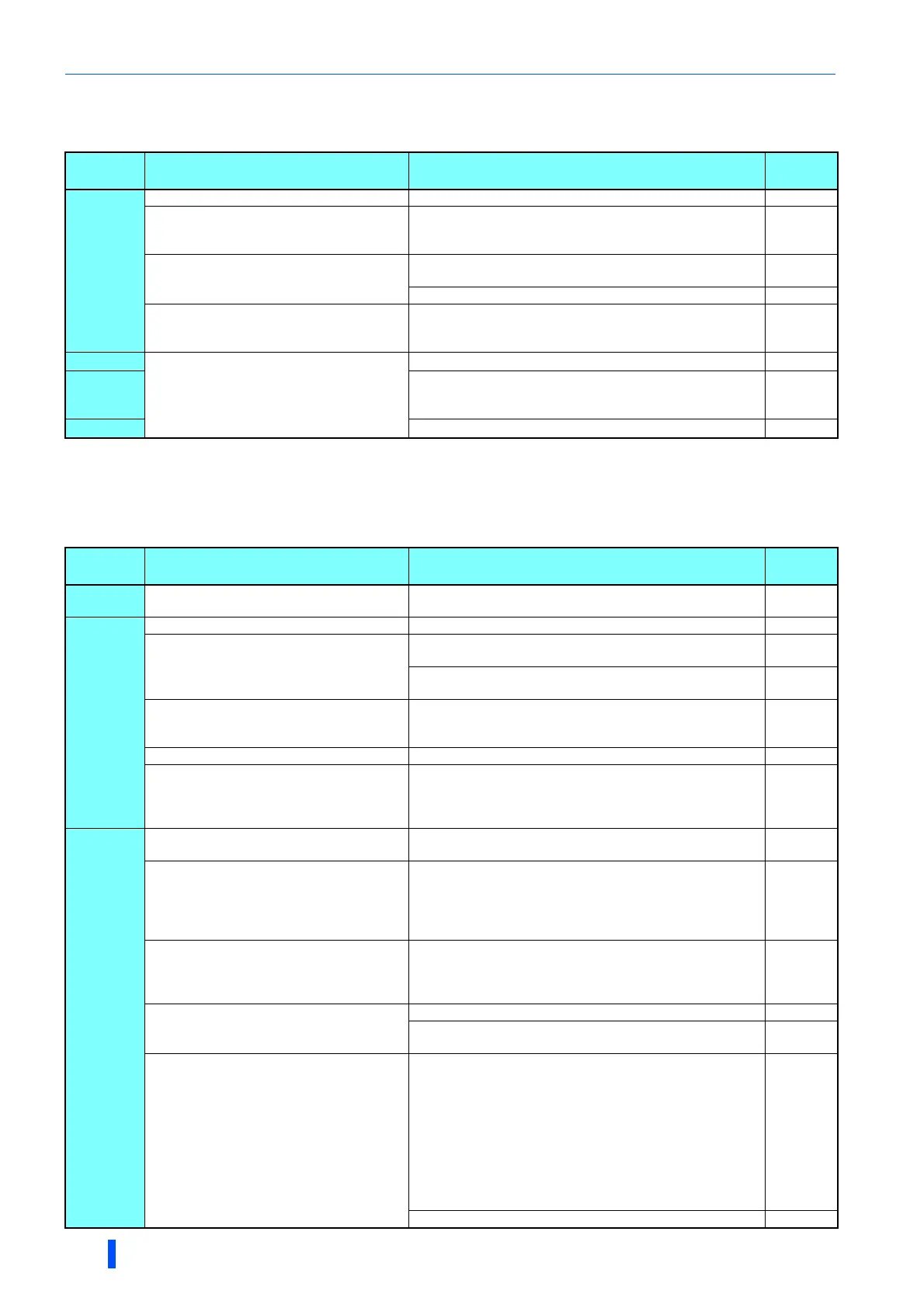

6.6.8 Speed varies during operation

Under Advanced magnetic flux vector control, Real sensorless vector control, vector control, and encoder feedback control,

the output frequency varies between 0 and 2 Hz as the load fluctuates. This is a normal operation and not a fault.

Check

points

Possible cause Countermeasure

Refer to

page

Parameter

Setting

Acceleration/deceleration time is too short. Increase the acceleration/deceleration time. 285

Torque boost (Pr.0, Pr.46, Pr.112) setting is

improper under V/F control, so the stall

prevention function is activated.

Increase/decrease the Pr.0 Torque boost setting value by

0.5% increments so that stall prevention does not occur.

597

The base frequency does not match the motor

characteristics.

Under V/F control, set Pr.3 Base frequency, Pr.47 Second V/

F (base frequency), and Pr.113 Third V/F (base frequency).

598

Under vector control, set Pr.84 Rated motor frequency. 164

Regeneration avoidance operation is

performed

If the frequency becomes unstable during regeneration

avoidance operation, decrease the setting of Pr.886

Regeneration avoidance voltage gain.

621

Load

Stall prevention (torque limit) function is

activated due to a heavy load.

Reduce the load weight.

Parameter

Setting

Set Pr.22 Stall prevention operation level (torque limit level)

higher according to the load. (If Pr.22 is set too high, an

overcurrent trip (E.OC[]) is likely to occur.)

185, 348

Motor

Check the capacities of the inverter and the motor.

Check

points

Possible cause Countermeasure

Refer to

page

Load

Load varies during an operation.

Select Advanced magnetic flux vector control, Real sensorless

vector control, vector control, or encoder feedback control.

164, 626

Input

signal

Frequency setting signal is varying. Check the frequency setting signal.

The frequency setting signal is affected by

EMI.

Set filter to the analog input terminal using Pr.74 Input filter

time constant , Pr.822 Speed setting filter 1.

413

Take countermeasures against EMI, such as using shielded

wires for input signal lines.

84

Malfunction is occurring due to the undesirable

current generated when the transistor output

unit is connected.

Use terminal PC (terminal SD when source logic) as a common

terminal to prevent a malfunction caused by undesirable

current.

50

Multi-speed command signal is chattering. Take countermeasures to suppress chattering.

Feedback signal from the encoder is affected

by EMI.

Place the encoder cable far from the EMI source such as main

circuit and power supply voltage.

Earth (ground) the shield of the encoder cable to the enclosure

using a metal P-clip or U-clip.

65

Parameter

Setting

Fluctuation of power supply voltage is too

large.

Under V/F control, change the Pr.19 Base frequency voltage

setting (approximately by 3%).

598

Pr.80 Motor capacity and Pr.81 Number of

motor poles are not appropriate for the motor

capacity under Advanced magnetic flux vector

control, Real sensorless vector control, vector

control, or PM sensorless vector control.

Check the settings of Pr.80 and Pr.81. 164

Wiring length exceeds 30 m when Advanced

magnetic flux vector control, Real sensorless

vector control, vector control, or PM

sensorless vector control is selected.

Perform offline auto tuning. 442

Under V/F control, wiring is too long and a

voltage drop occurs.

In the low-speed range, set 0.5% in Pr.0 Torque boost. 597

Change the control method to Advanced magnetic flux vector

control or Real sensorless vector control.

164

Hunting occurs by the generated vibration, for

example, when structural rigidity at load side is

insufficient.

Disable automatic control functions, such as the energy saving

operation, fast-response current limit operation, torque limit,

regeneration avoidance function, Advanced magnetic flux

vector control, Real sensorless vector control, vector control,

encoder feedback control, droop control, stall prevention, online

auto tuning, notch filter, and orientation control.

Under PID control, set smaller values to Pr.129 PID

proportional band and Pr.130 PID integral time.

Adjust so that the control gain decreases and the level of safety

increases.

Change Pr.72 PWM frequency selection setting. 277

Loading...

Loading...