Position control under vector control and PM sensorless vector control

252

PARAMETERS

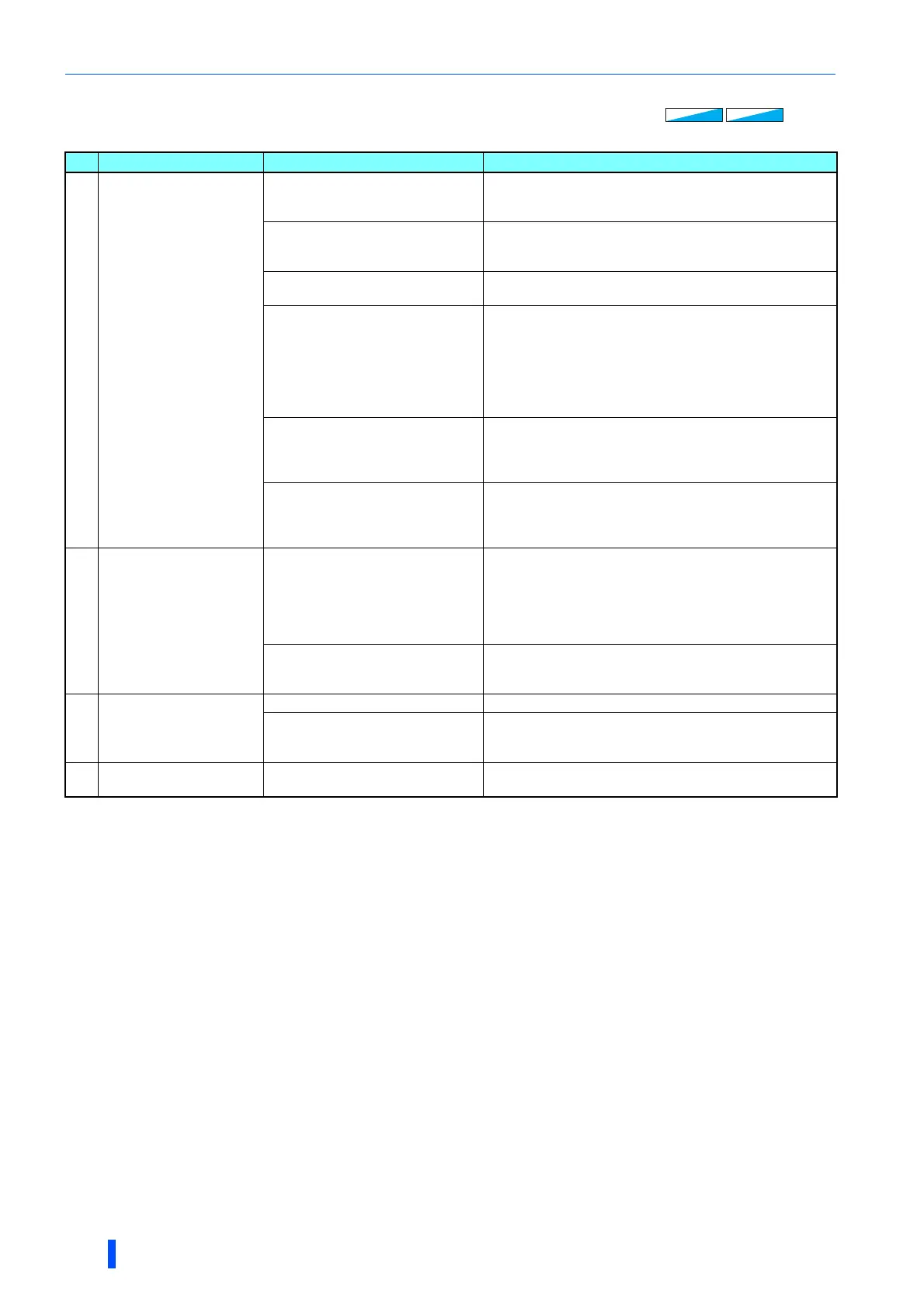

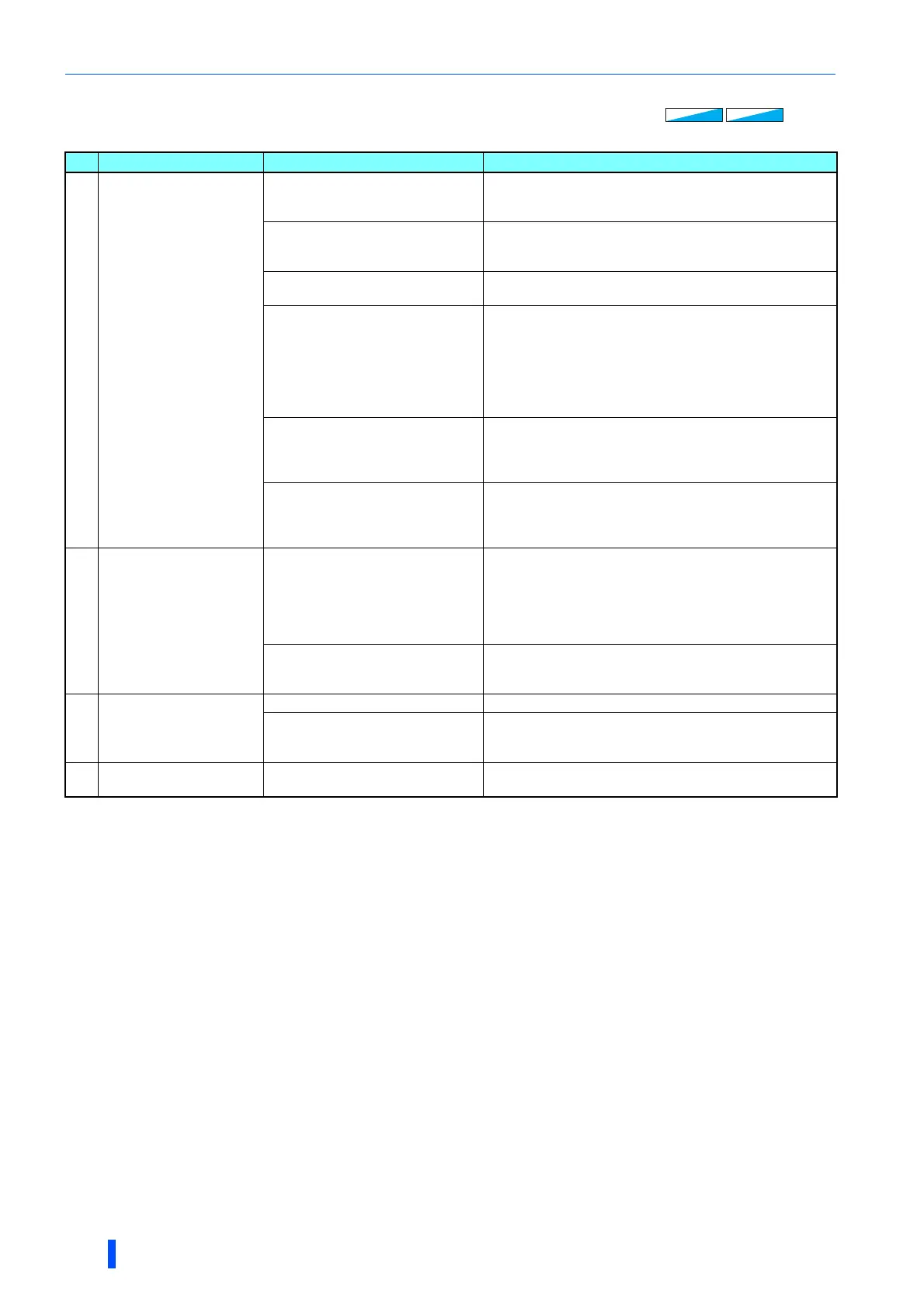

5.5.9 Troubleshooting in position control

Condition Cause Countermeasure

1 The motor does not rotate.

There is incorrect phase sequence

between the motor wiring and

encoder wiring.

Check the wiring. (Refer to page 66.)

Control mode selection setting Pr.800

Control method selection is not

appropriate.

Check the Pr.800 setting. (Refer to page 164.)

No servo ON or stroke end signals

(STF/STR) are input.

Check if a signal is properly input.

A command pulse or position pulse

sign (NP) is not correctly input.

Check if the command pulse is properly input. (check the

accumulated value for command pulses in Pr.430 Pulse

monitor selection).

Check the command pulse type in Pr.428 Command pulse

selection.

Check that the position pulse sign (NP) is assigned to an input

terminal. (inverter pulse input)

The setting in Pr.419 Position

command source selection

(position command source selection)

is not correct.

Check the position command source selection in Pr.419.

When simple position control by a

point table (Pr.419= "0") is used , the

position feed length set by Pr.465 to

Pr.494 is not correct.

Check the position feed length in Pr.465 to Pr.494.

2

The position is unfavorably

shifted.

A command pulse is not correctly

input.

Check the command pulse type in Pr.428 Command pulse

selection.

Check if the command pulse is properly input. (check the

accumulated value of command pulses in Pr.430)

Check that the position pulse sign (NP) is assigned to an input

terminal. (inverter pulse input)

The command is affected by noise.

Noise is superpositioned on the

encoder feedback signals.

Set Pr.72 PWM frequency selection lower.

Change the earthing (grounding) position of the shielded

cable. Alternatively, do not connect it.

3

Hunting occurs in the motor

or the machine.

Position loop gain is too high. Set Pr.422 Position control gain lower.

Speed loop gain is too high.

Perform easy gain tuning.

Set Pr.820 Speed control P gain 1 lower and Pr.821 Speed

control integral time 1 higher.

4

Machine movement is

unstable.

Acceleration/deceleration time

settings are affecting adversely.

Set Pr.7 Acceleration time and Pr.8 Deceleration time

lower.

Vector

Vector

PM

PM

Loading...

Loading...